A kind of packing method of LED core particle and LED core particle packing structure

A packaging method and packaging structure technology, applied in the manufacturing of semiconductor devices, electrical components, semiconductor/solid-state devices, etc., can solve the problems of uneven brightness and darkness of the outer ring core particles, identification and other problems, and achieve high efficiency, low cost, and reduced The effect of the alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

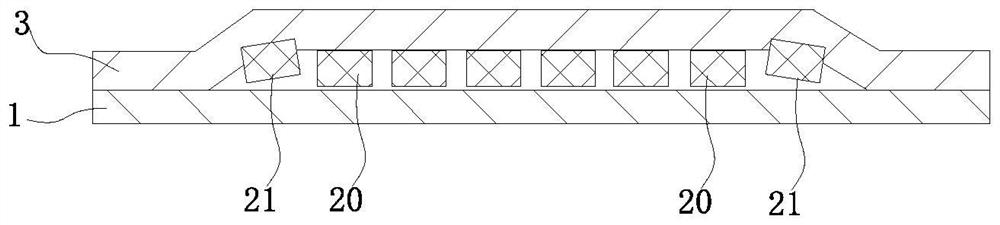

[0029] Such as figure 1 and figure 2 shown. in figure 1 It is a schematic diagram of sticking release paper after the core particles are fixed on the film. exist figure 1 Among them, the number 1 represents the adhesive film, 20 represents the non-outermost non-outer ring core particle, 21 represents the outermost outer ring core particle among all the core particles, and 3 represents the release paper.

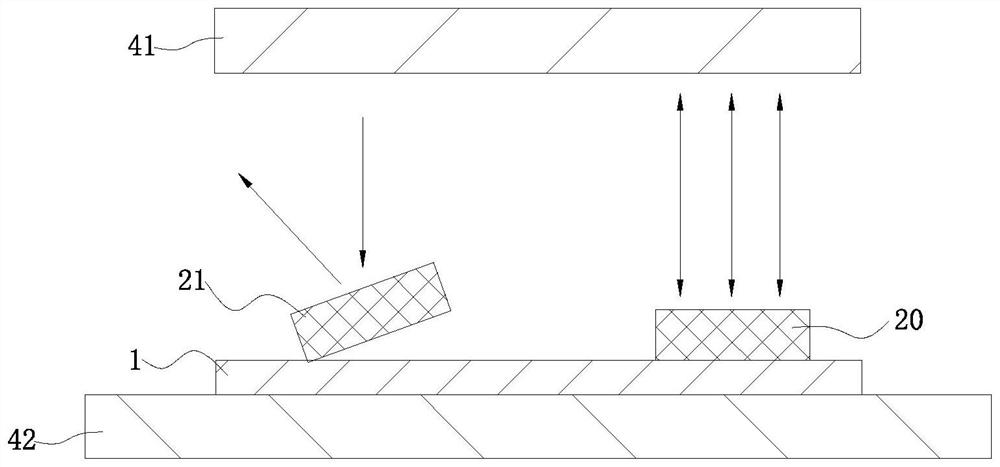

[0030] figure 2 It is a schematic diagram of non-outer ring core particles 20 and outer ring core particles 21 under the CCD lens of the die bonder. exist figure 2 Among them, the reference number 41 represents the CCD lens of the die bonder, and 42 represents the plate of the die bonder, and the arrow in the figure represents the light path.

[0031] The applicant found in the research that the main reason for the uneven brightness and darkness of the outer ring core particles 21 is that the outer ring core particles 21 are affected by the bonding force of the adh...

Embodiment 2

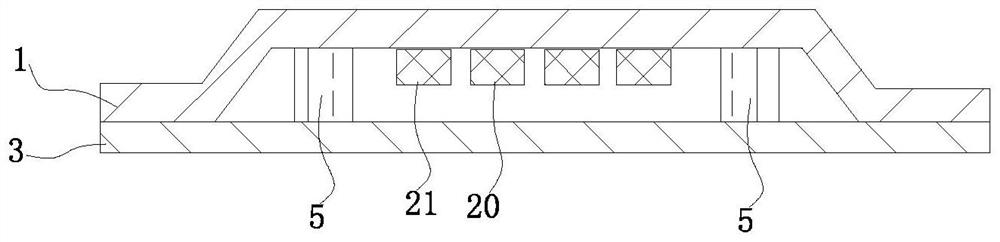

[0043] refer to Figure 3-Figure 5, this embodiment provides an LED chip packaging structure produced by the LED chip packaging method proposed in Example 1, including an adhesive film, a plurality of LED chips, a cover and a support, wherein a plurality of LED The core particles are fixed on the adhesive film 1, and are divided into outer ring core particles 21 located at the edge and non-outer ring core particles 20 located in the outer ring core particles 21 according to their positional relationship; the support is placed on the adhesive film There is fixed on one side of the core particle, the support 5 ring is arranged on the edge of the outermost core particle, and the maximum thickness of the support 5 is greater than the maximum thickness of the core particle;

[0044] The cover covers the support 5 and all the core particles, and is fixed on the adhesive film 1 and / or the support 5, and the support 5 prevents the cover from directly contacting the position of the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com