Novel cylindrical button battery

A button battery and cylinder technology, applied in the field of new cylindrical button batteries, can solve problems such as corrosion, battery gas, burrs that are easy to pierce, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

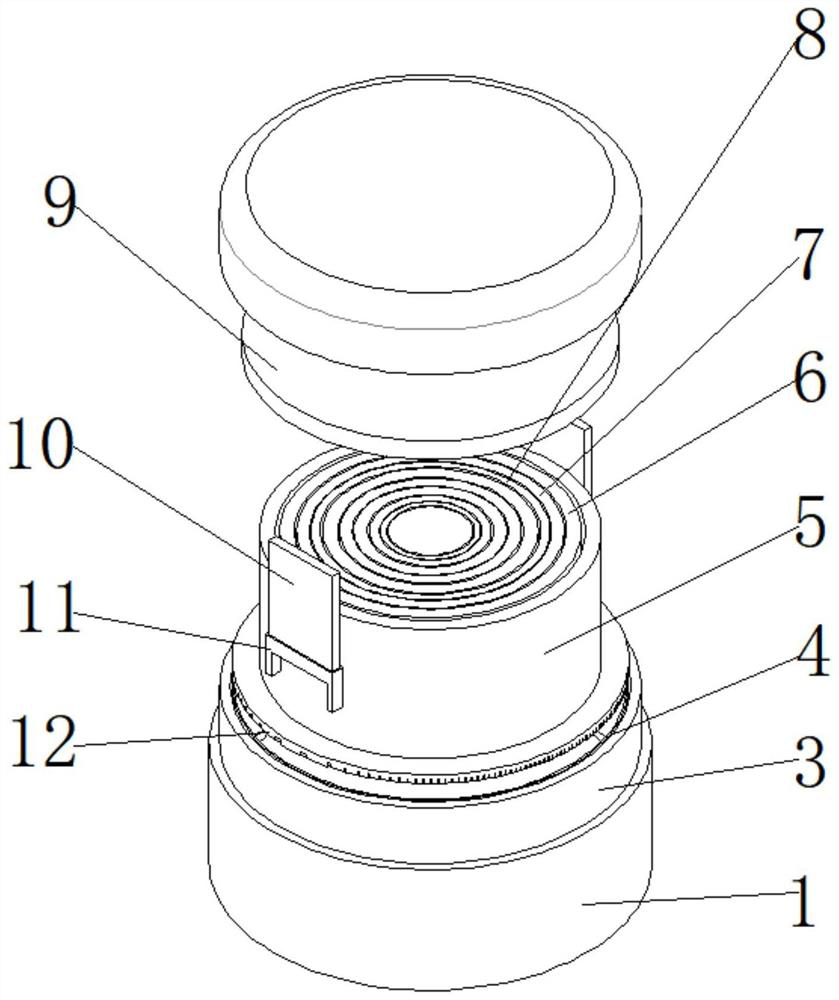

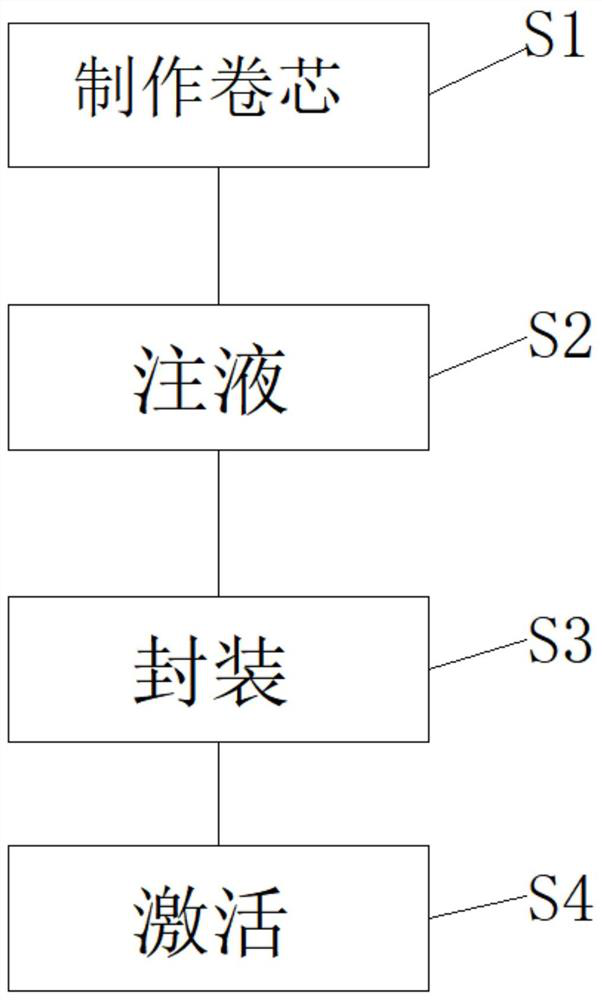

[0028] see Figure 1-2 , a novel cylindrical button cell, comprising membrane case one 2, membrane case two 3 and winding core 5, membrane case one 2 being installed above membrane case two 3, winding core 5 being installed on the inner side of membrane case two 3, membrane case An anti-corrosion sheet 4 is fixedly installed on the inner side of the first 2, and the anti-corrosion sheet 4 can play a protective role on the inner winding core 5, and a sealing gasket 9 is fixedly installed on the inner side of the membrane shell two 3, and the sealing gasket 9 can protect the winding core 5. To protect the winding core 5 from damage due to external force, a protective sleeve 1 is fixedly installed at the junction of the membrane shell 1 2 and the membrane shell 2 3, and the connection of the membrane shell 1 2 and the membrane shell 2 3 can be fixed through the protective sleeve 1 Protection at the junction of membrane shell 1 2 and membrane shell 2 3 to avoid liquid leakage caus...

Embodiment 2

[0037] Based on Example 1, such as Figure 1-2 , A wool top 12 is fixedly installed under the core 5 , the negative electrode ear 11 runs through the wool top 12 , and the bottom of the core 5 can be protected by the wool top 12 .

[0038] Working principle: When installing the winding core 5, first install the top 12 on the bottom of the membrane shell 12, and then install the winding core 5 above the top 12. During installation, the negative electrode ear 11 runs through the top 12, and then connects to the membrane shell 12. The inner side of shell one 2 is dripped with electrolyte.

[0039] When encapsulating, high-frequency heating is used to seal the junction of membrane shell 1 2 and membrane shell 2 3, and then the anti-corrosion sheet 4 can prevent the inner solution from corroding the shell, and then the protective sleeve 1 is fixed on the membrane shell 1 2 and membrane shell 2 3, after the installation is completed, it is sealed at high temperature, so that the pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap