PDINH-coated TiO2 photocatalyst as well as preparation method and application thereof

A technology of photocatalyst and titanium dioxide, which is applied in the field of PDINH@TiO2 photocatalyst and its preparation, can solve the problems of not being able to suppress the rapid recombination of photogenerated electrons and holes, and reducing the photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

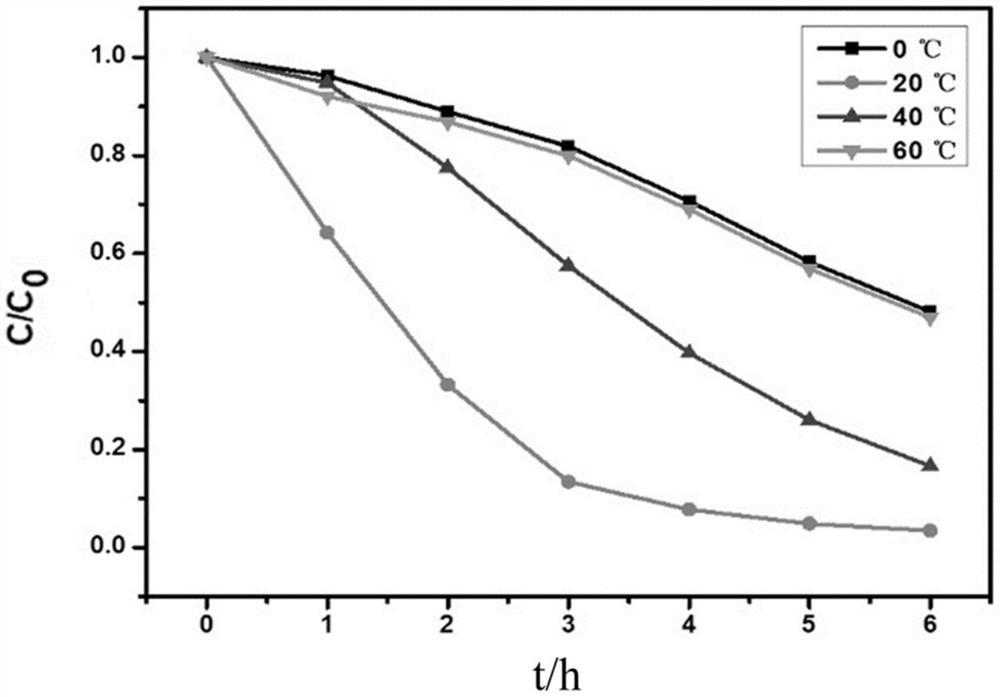

[0032] Examples 1-4 are PDINH@TiO 2 Photocatalyst TiO 2 As an example of the load temperature study when loading PDINH, Example 1 is 0°C, Example 2 is 20°C, Example 3 is 40°C, and Example 4 is 60°C.

[0033] Example 1

[0034] A PDINH@TiO 2 The preparation method of photocatalyst, concrete steps are as follows:

[0035] (1) Weigh 0.3g TiO 2, measure 10mL H 2 SO 4 Place it in a 250mL beaker and stir it magnetically for 12h to obtain a mixed solution.

[0036] (2) Add 0.3g PDINH to the mixture of (1) and sonicate for 10min, then slowly add 100mL distilled water to the above solution, then put the 250mL beaker containing the solution into a 2000mL beaker and add ice water for ice water cooling , and keep the temperature at 0°C and stir for 4h. Finally, centrifuged at 10000rpm / min, alternately washed with absolute ethanol and distilled water for 3 times, and dried at 60°C for 12h to obtain PDINH@TiO 2 powder.

[0037] Catalyst performance evaluation, the photocatalytic d...

Embodiment 2

[0040] A PDINH@TiO 2 The preparation method of photocatalyst, concrete steps are as follows:

[0041] (1) Weigh 0.3g TiO 2 , measure 10mL H 2 SO 4 Place it in a 250mL beaker and stir it magnetically for 12h to obtain a mixed solution.

[0042] (2) Add 0.3g of PDINH to the mixture of (1) and sonicate for 10min, then slowly add 100mL of distilled water into the above solution, and then stir the solution at 20°C for 4h. Finally, centrifuged at 10000rpm / min, alternately washed with absolute ethanol and distilled water for 3 times, and dried at 60°C for 12h to obtain PDINH@TiO 2 powder.

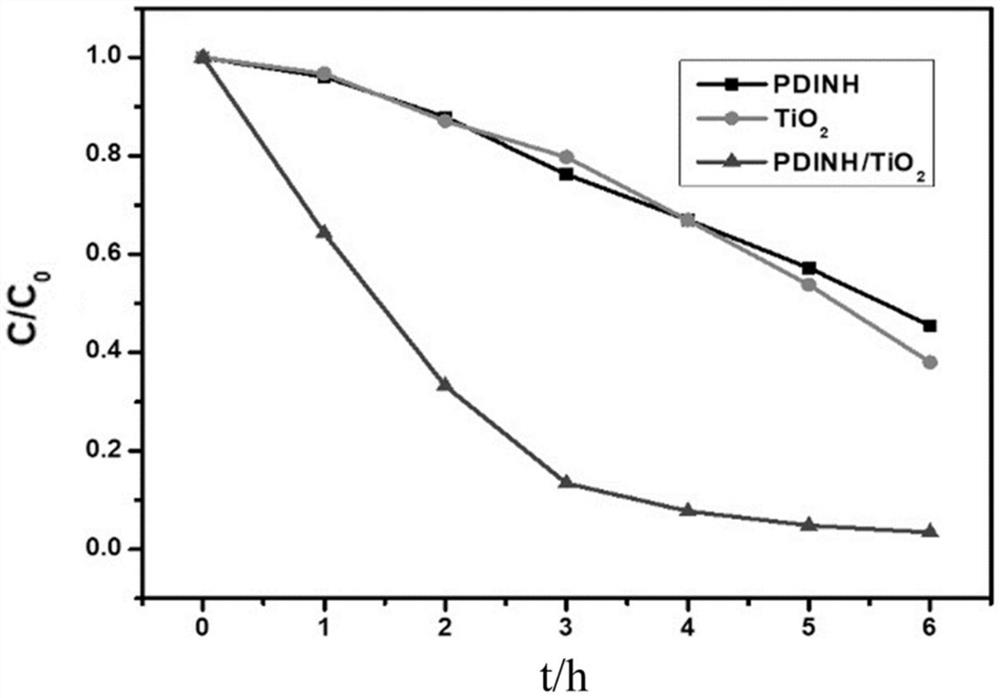

[0043] like figure 1 As shown, the loading temperature of the catalyst in this example is 20°C, and the prepared PDINH@TiO 2 The removal rate of catalyst degraded phenol was 91.29%.

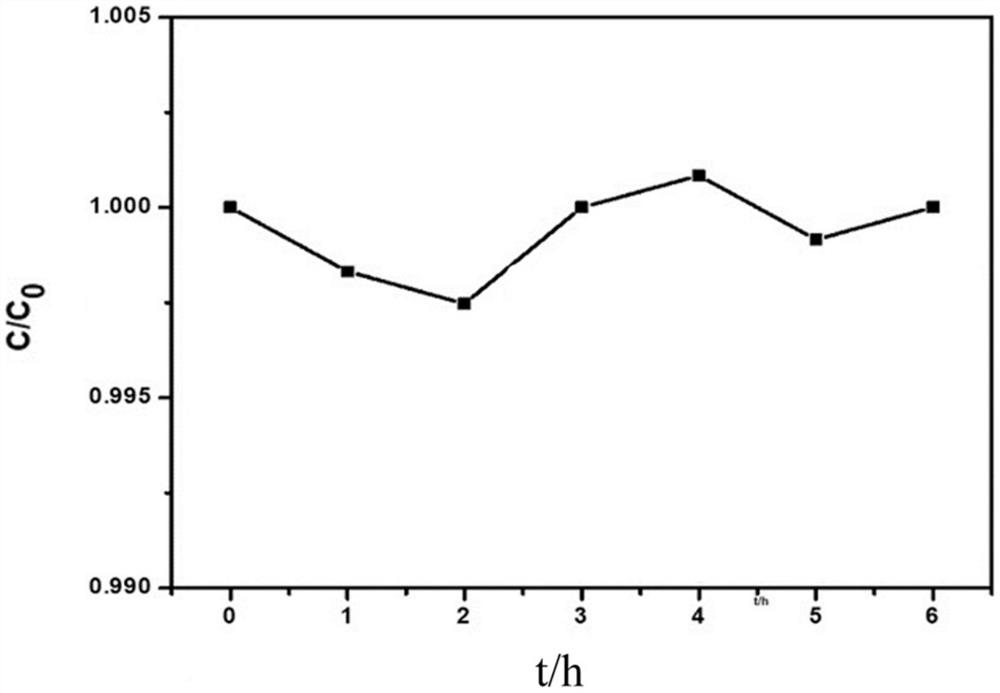

[0044] figure 2 It is the performance curve of self-degradation of 6ppm phenol solution under 300W simulated sunlight, by figure 2 It can be seen that the 6 ppm phenol solution basically does not self-deg...

Embodiment 3

[0047] A PDINH@TiO 2 The preparation method of photocatalyst, concrete steps are as follows:

[0048] (1) Weigh 0.3g TiO 2 , measure 10mL H 2 SO 4 Place it in a 250mL beaker and stir it magnetically for 12h to obtain a mixed solution.

[0049] (2) Add 0.3g of PDINH to the mixture of (1) and sonicate for 10min, then slowly add 100mL of distilled water into the above solution, and then stir the solution at 40°C for 4h. Finally, centrifuged at 10000rpm / min, alternately washed with absolute ethanol and distilled water for 3 times, and dried at 60°C for 12h to obtain PDINH@TiO 2 powder.

[0050] like figure 1 As shown, the loading temperature of the catalyst in this example is 40°C, and the prepared PDINH@TiO 2 The removal rate of catalyst degraded phenol was 80.33%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com