Method for producing electroplating-grade copper oxide by utilizing acidic etching waste liquid

A technology of electroplating copper oxide and acidic etching waste liquid, which is applied in the direction of copper oxide/copper hydroxide, etc., to achieve the effects of improving collection efficiency, enhancing purity, and increasing production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail with reference to the accompanying drawings.

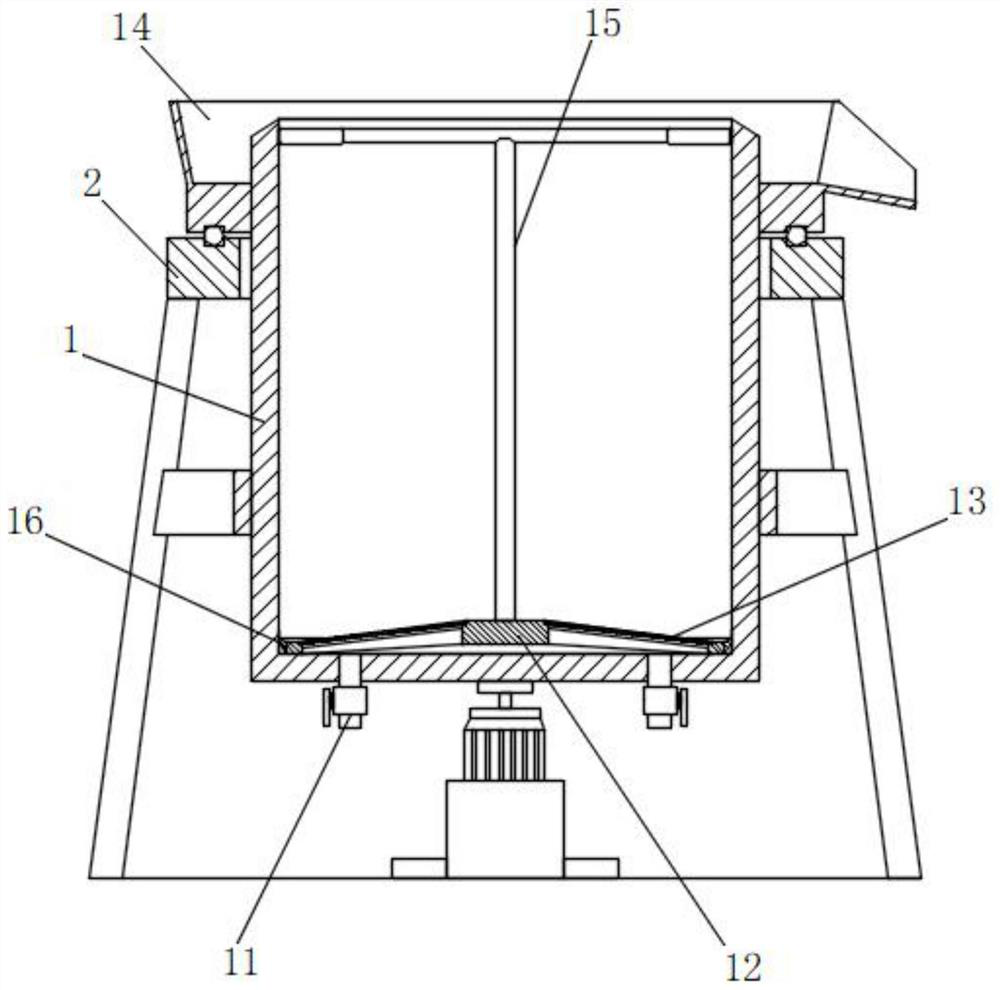

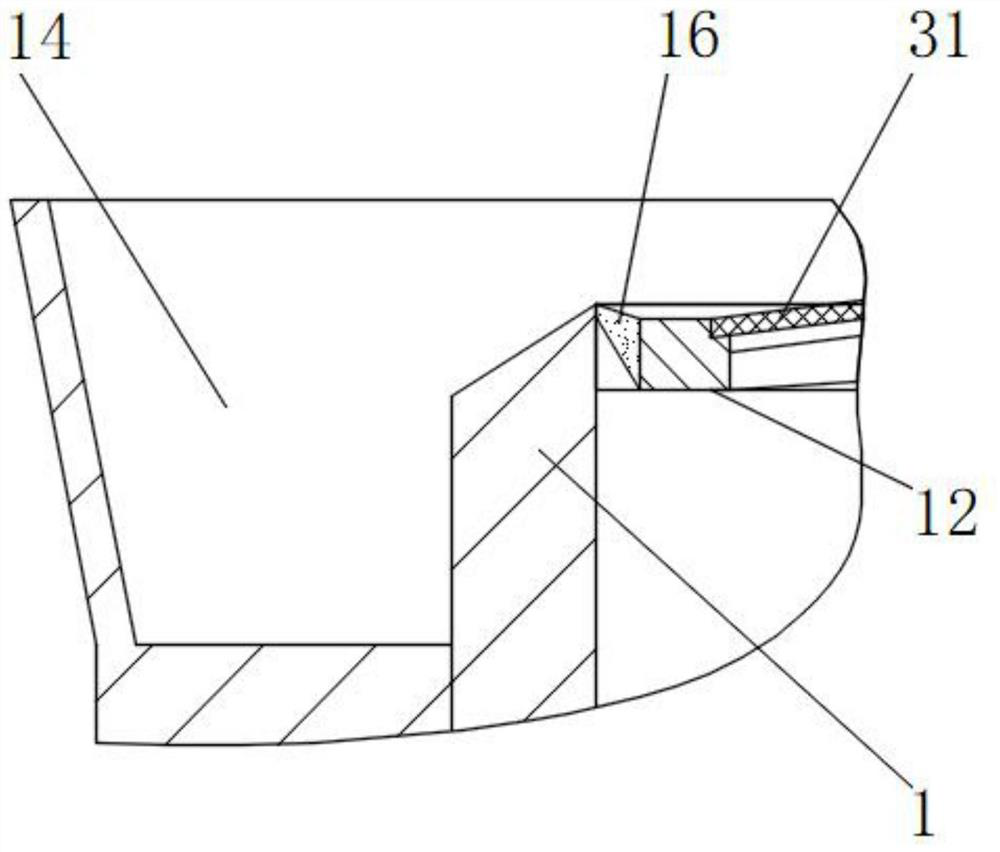

[0025]The present invention providesFigure 1-2The shown method for producing electroplating-grade copper oxide using acid etching waste liquid includes the following steps:

[0026]Step 1. Set up a rotatable reaction cylinder 1 and rotate it through the support frame 2. Install a lifting scraper 12 that can slide up and down inside the reaction cylinder 1, and install a precision filter 13 inside the lifting scraper 12 , After inserting the lifting scraper 12 into the bottom of the reaction cylinder 1, the acidic etching solution after filtering and removing impurities is introduced into the reaction cylinder 1 to prepare for processing;

[0027]Step 2. Gradually add an oxidant to the reaction cylinder 1 to oxidize the free copper ions in the acid etching solution, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com