Adhesive composition, easy-to-pull adhesive tape as well as preparation method and application of easy-to-pull adhesive tape

An easy-to-pull adhesive tape and composition technology, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems of unfavorable heavy work, low bonding strength, and difficulty in ensuring the fixation of adherends, etc., to achieve easy heavy work, good The effect of cushioning performance, excellent removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

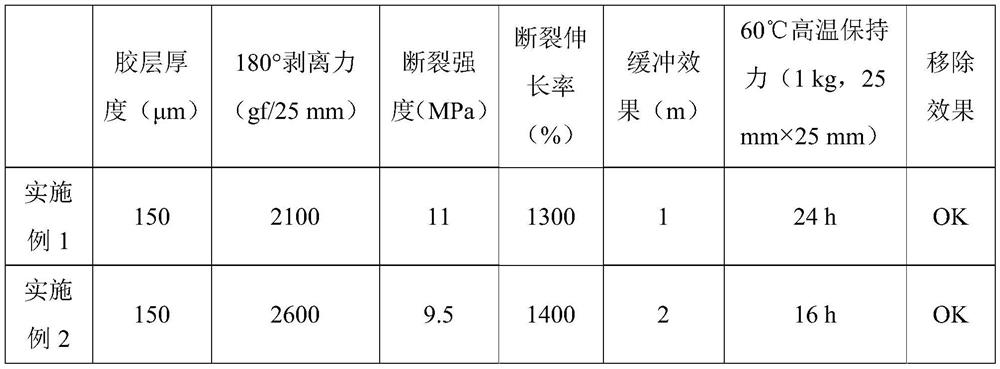

[0087] An adhesive composition comprising the following components in parts by weight: 40 parts of SBS (D1101), 20 parts of SIS (4111), 24 parts of rosin resin (RE100L), 25 parts of terpene resin (TR100), 5 parts C5 petroleum resin (BT-H100), 4 parts of titanium dioxide, 1 part of color paste dispersant.

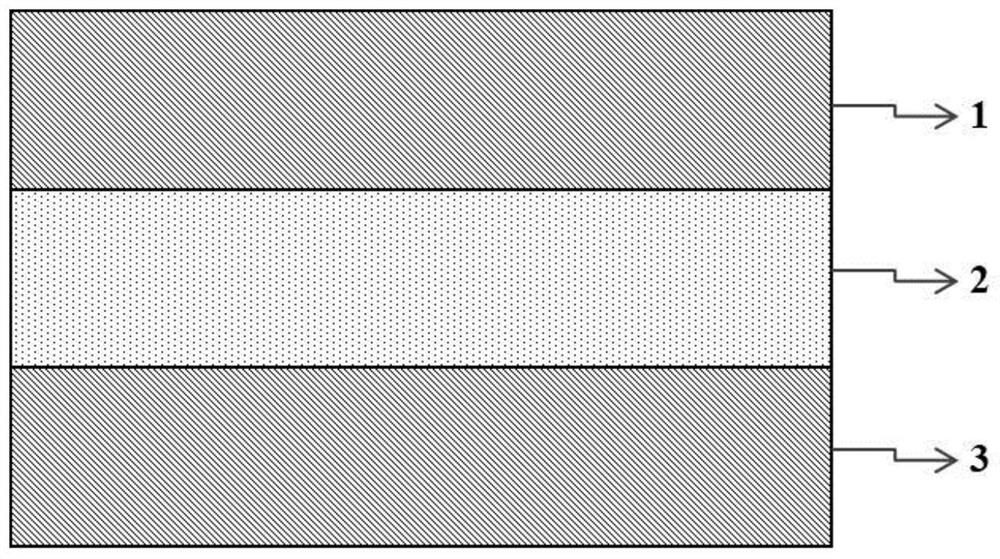

[0088] The adhesive composition is used to prepare an easy-pull tape, and the structural representation of the easy-pull tape is as follows: figure 1 As shown, it includes a first release material layer 1, an adhesive layer 2 and a second release material layer 3 in sequence; wherein, the thickness of the first release material layer is 25 μm, the thickness of the adhesive layer is 150 μm, and the second release material layer The thickness of the type material layer is 50 μm.

[0089] The preparation method of described easy pull adhesive tape is as follows:

[0090] (1) Mix titanium dioxide, color paste dispersant, 4 parts of rosin resin and 11 parts of butyl acetate (BA...

Embodiment 2

[0094] An adhesive composition comprising the following components in parts by weight: 30 parts of SBS (D1101), 20 parts of SIS (4111), 14 parts of rosin resin (RE100L), 35 parts of terpene resin (TR100), 5 parts C5 petroleum resin (BT-H100), 4 parts of titanium dioxide, 1 part of color paste dispersant.

[0095] The adhesive composition is used to prepare an easy-pull tape, and the structural representation of the easy-pull tape is as follows: figure 1 As shown, it includes a first release material layer 1, an adhesive layer 2 and a second release material layer 3 in sequence; wherein, the thickness of the first release material layer is 36 μm, the thickness of the adhesive layer is 150 μm, and the second release material layer The thickness of the type material layer is 75 μm.

[0096] The preparation method of described easy pull adhesive tape is as follows:

[0097] (1) Mix titanium dioxide, color paste dispersant, 4 parts of rosin resin and 11 parts of butyl acetate (BA...

Embodiment 3

[0101] An adhesive composition comprising the following components in parts by weight: 30 parts of SBS (D1192), 20 parts of SIS (D1114), 24 parts of rosin resin (RE100L), 25 parts of terpene resin (TR100), 5 parts C5 petroleum resin (wingtack 95), 4 parts of titanium dioxide, 1 part of color paste dispersant.

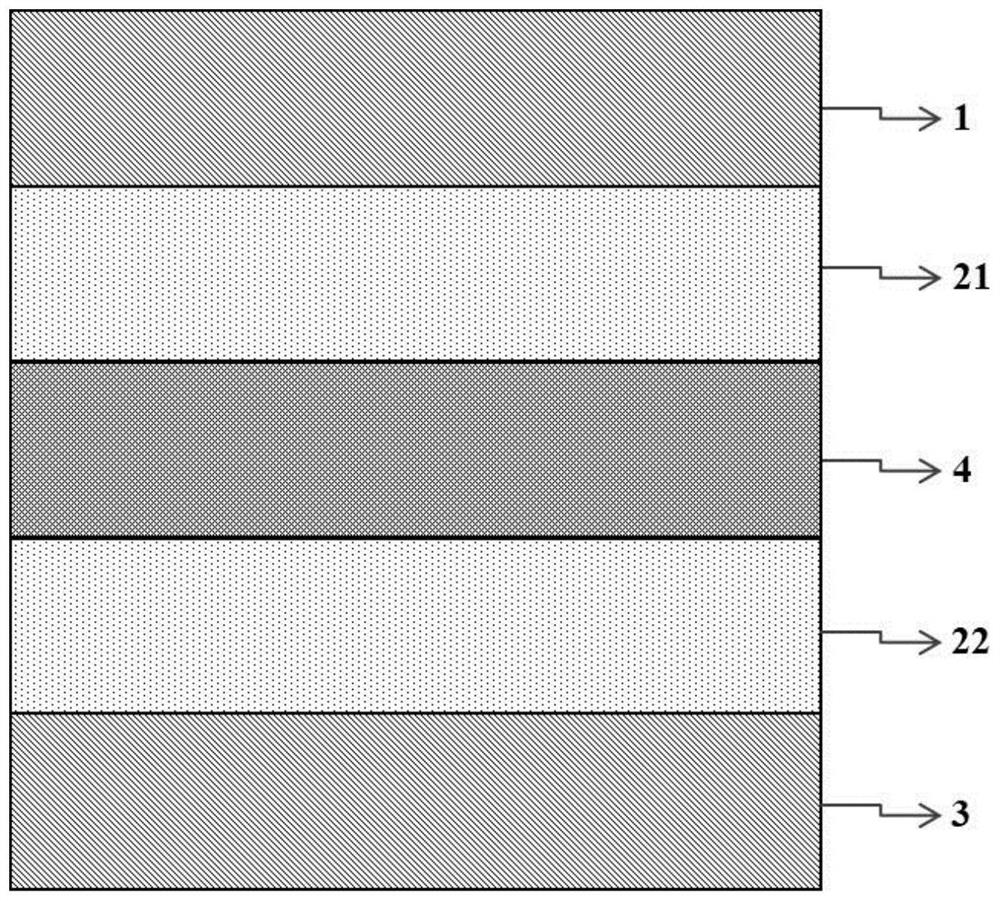

[0102] The adhesive composition is used to prepare the easy-pull tape containing the base material, and the structural representation of the easy-pull tape containing the base material is as follows: figure 2 As shown, the first release material layer 1, the first adhesive layer 21, the elastic substrate layer 4, the second adhesive layer 22 and the second release material layer 3 are sequentially included; wherein, the first release material layer The thickness is 25 μm, the thickness of the first adhesive layer, the elastic substrate layer and the second adhesive layer are all 50 μm, the thickness of the second release material layer is 50 μm; the material of the ela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com