Twin dissimilar material composite radial flow impeller and manufacturing process thereof

A dissimilar material, composite technology, used in non-variable-capacity pumps, liquid fuel engines, non-variable-capacity engines, etc., can solve the problem of limited power or torque, many parts, loose impeller or turbine impeller connection parts, etc. problems, to achieve the effect of reducing weight, improving rigidity and strength, and reducing the difficulty of processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

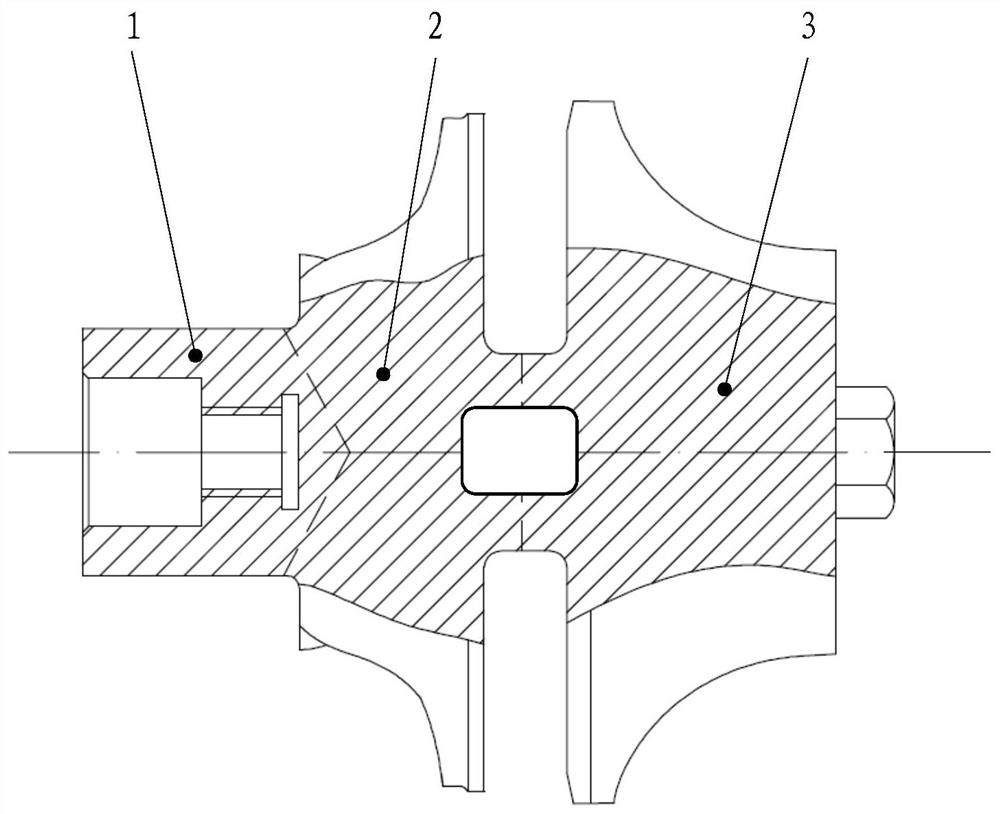

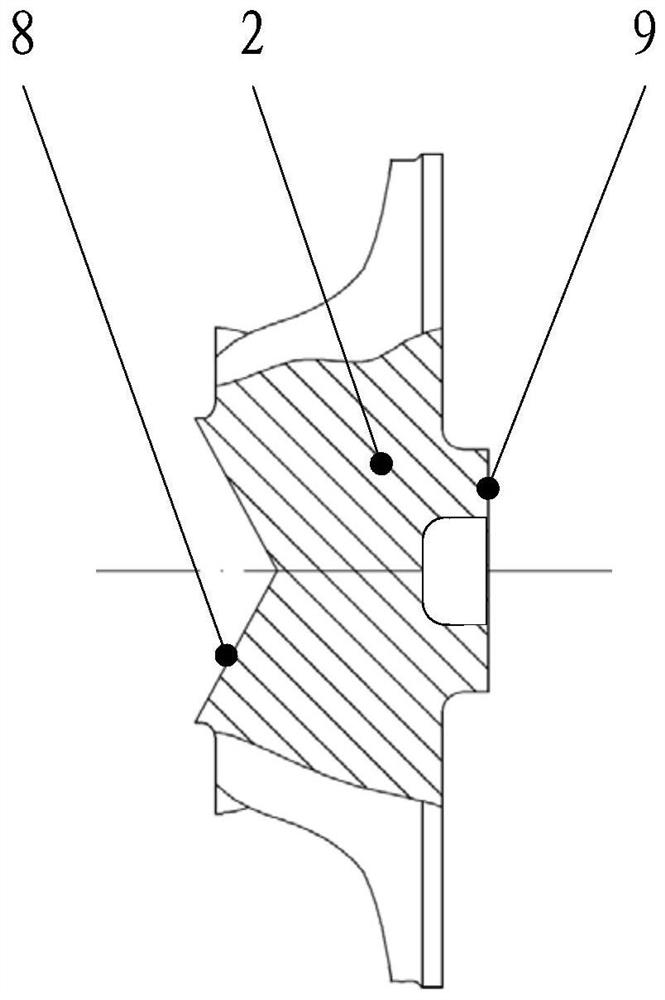

[0027] A twin dissimilar material composite radial flow impeller includes a connecting shaft 1, a radial compressor impeller 2 and a radial turbine impeller 3, the connecting shaft 1, the radial compressor impeller 2 and the radial turbine impeller 3 are an integrated structure, and the connecting shaft 1. Radial compressor impeller 2 and radial turbine impeller 3 are located on the same axis, such as figure 1 shown;

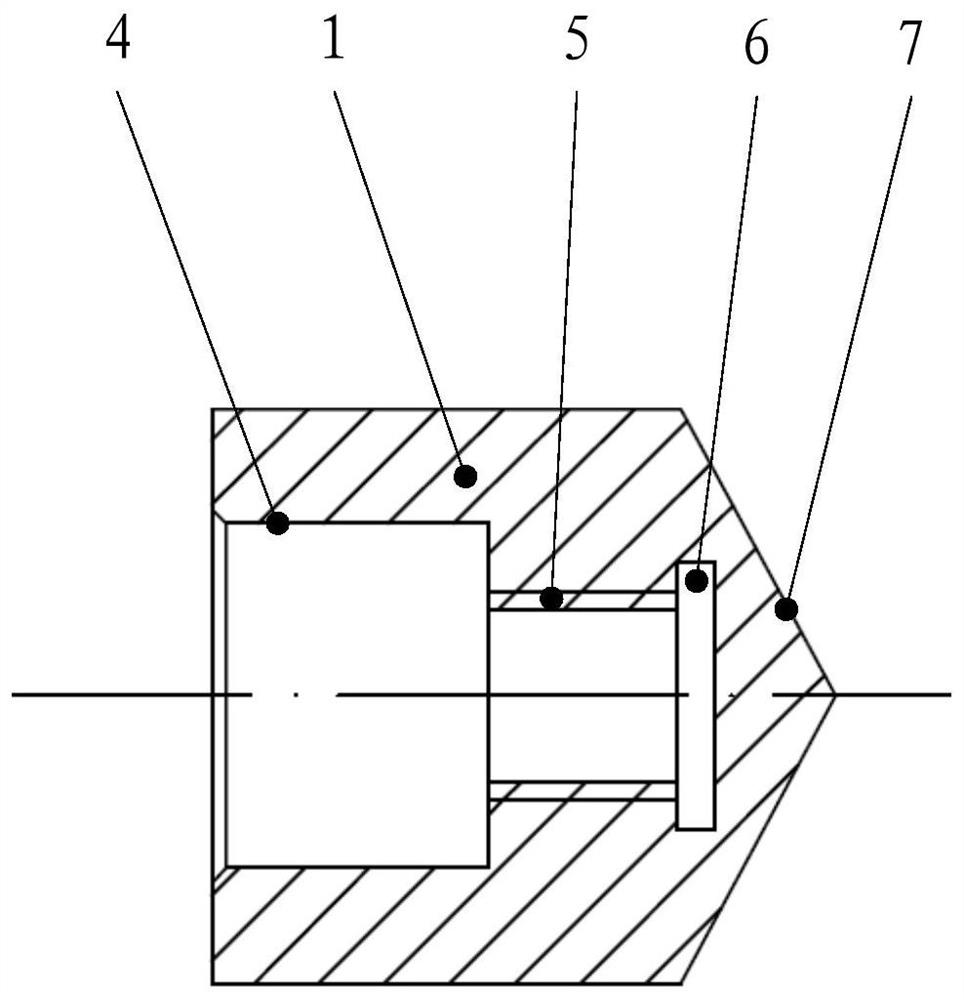

[0028] The central part of one end of the connecting shaft 1 has a round hole 4 for connecting with the rotor, the other end of the connecting shaft 1 has a tapered end face 7 welded with the radial compressor impeller 2, and the round hole of the connecting shaft 1 4 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com