Preparation method of pumpkin seed and buckwheat sugar-free yoghourt and pumpkin seed and buckwheat sugar-free yoghourt

A production method and pumpkin seed technology are applied in the production of pumpkin seed buckwheat sugar-free yogurt and the field of pumpkin seed buckwheat sugar-free yogurt, which can solve the problems of inability to meet the dietary needs of the three-high population, and achieve prevention of cardiovascular and cerebrovascular diseases and thrombosis. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

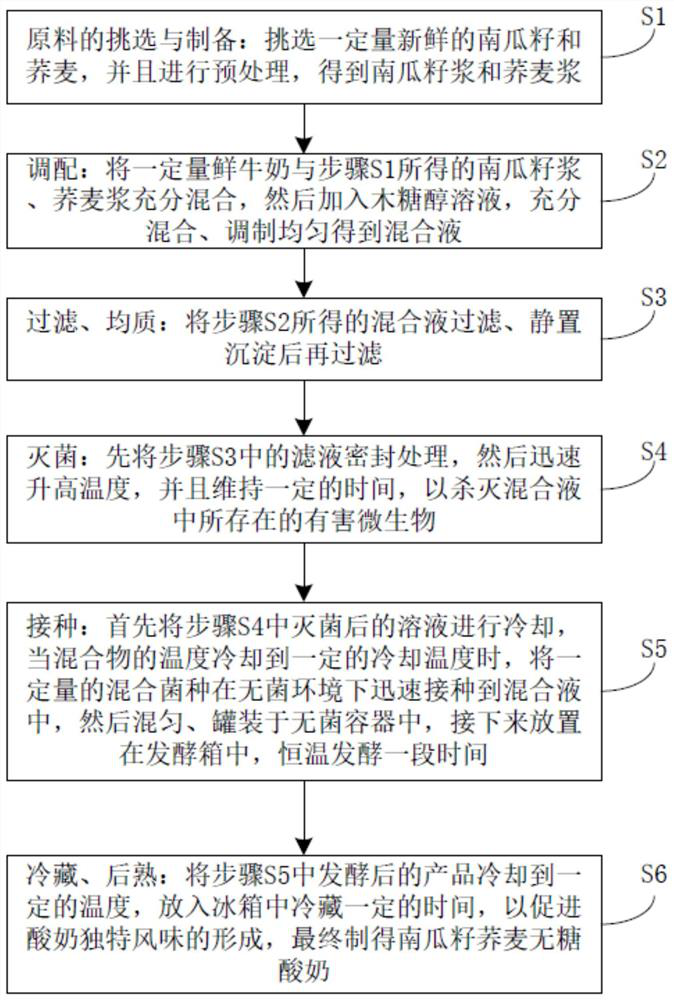

Method used

Image

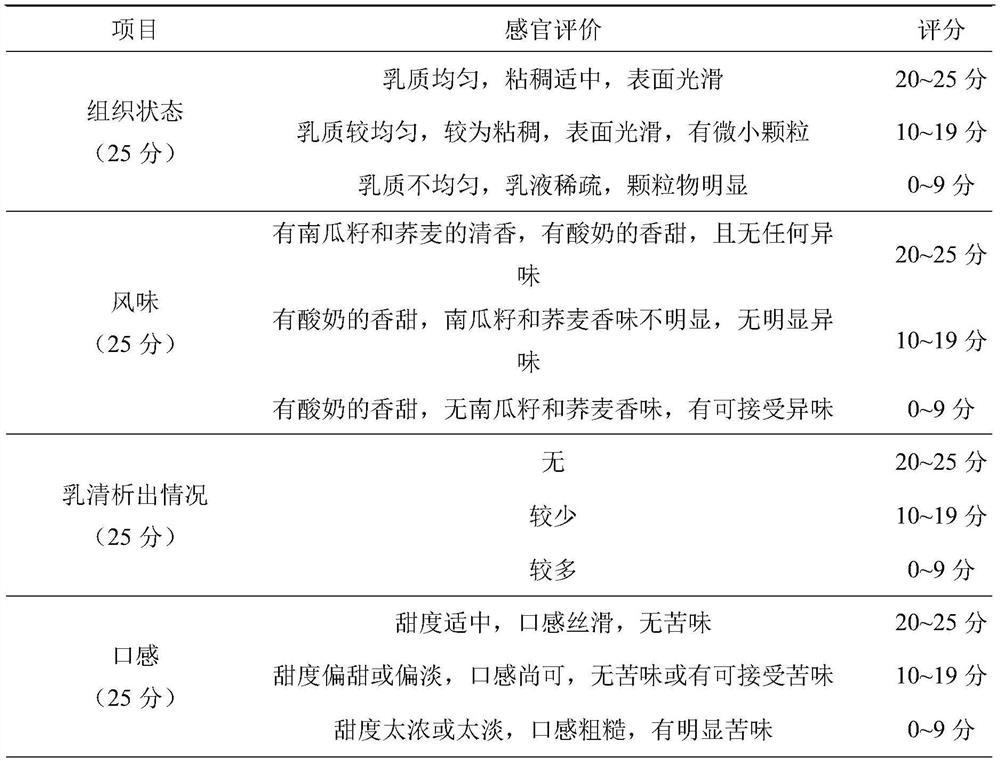

Examples

specific Embodiment 1

[0032] 1. Production of pumpkin seed buckwheat sugar-free yogurt: In this example, 100 parts of fresh milk is used as the benchmark

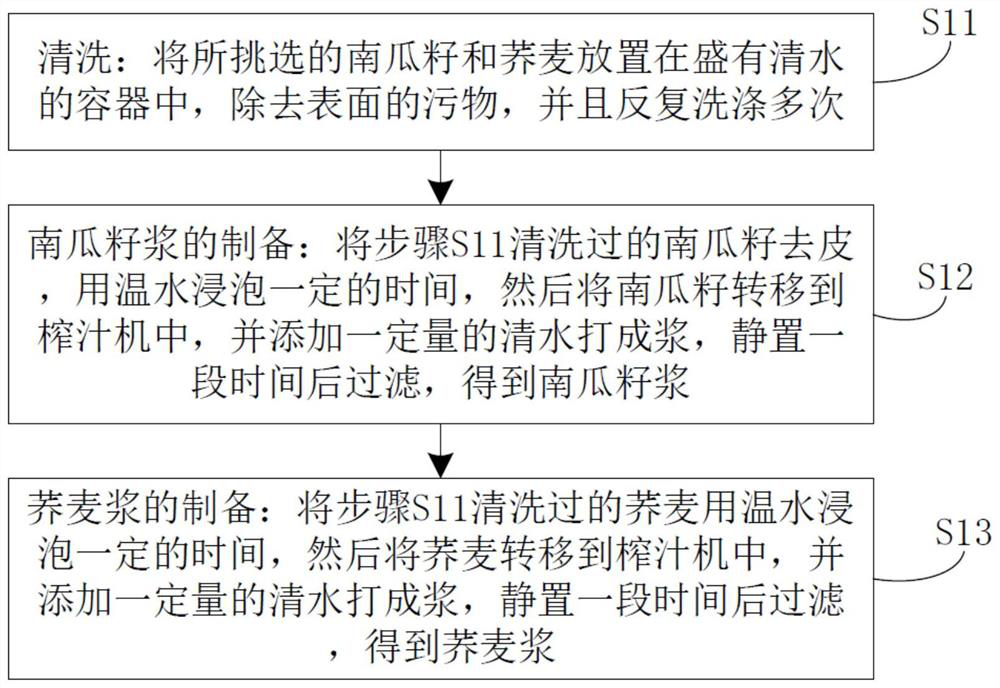

[0033] 1. Selection and preparation of raw materials: According to 100 parts by weight of fresh milk, 5 parts of fresh pumpkin seeds and 10 parts of buckwheat are selected and pretreated to obtain pumpkin seed pulp and buckwheat pulp.

[0034] In this step, firstly, cleaning is carried out, that is, the selected pumpkin seeds and buckwheat are placed in a container filled with clear water to remove the dirt on the surface, and washed repeatedly three times;

[0035] Then, prepare pumpkin seed pulp: peel the washed pumpkin seeds, soak them in warm water at 40°C for 3 hours, then transfer the pumpkin seeds to a juice extractor, add 35 parts of water to make a slurry, let stand for 5 hours, and then filter to obtain pumpkin seed paste;

[0036] Next, prepare the buckwheat pulp: soak the buckwheat in warm water at 40°C for 3 hours, then transfer th...

specific Embodiment 2

[0047] 1. Production of pumpkin seed buckwheat sugar-free yogurt: In this example, 100 parts of fresh milk is used as the benchmark

[0048] 1. Selection and preparation of raw materials: According to 100 parts by weight of fresh milk, 17 parts of fresh pumpkin seeds and 21 parts of buckwheat are selected and pretreated to obtain pumpkin seed pulp and buckwheat pulp.

[0049] In this step, firstly, cleaning is carried out, that is, the selected pumpkin seeds and buckwheat are placed in a container filled with clear water to remove the dirt on the surface, and washed repeatedly three times;

[0050] Then, prepare pumpkin seed pulp: peel the washed pumpkin seeds, soak them in warm water at 50°C for 5 hours, then transfer the pumpkin seeds to a juicer, add 136 parts of water to make a slurry, let stand for 8 hours, and then filter to obtain pumpkin seed paste;

[0051] Next, prepare the buckwheat pulp: soak the buckwheat in warm water at 50°C for 5 hours, then transfer the buckw...

specific Embodiment 3

[0060] 1. Production of pumpkin seed buckwheat sugar-free yogurt: In this example, 100 parts of fresh milk is used as the benchmark

[0061] 1. Selection and preparation of raw materials: According to 100 parts by weight of fresh milk, 14 parts of fresh pumpkin seeds and 21 parts of buckwheat are selected and pretreated to obtain pumpkin seed pulp and buckwheat pulp.

[0062] In this step, firstly, cleaning is carried out, that is, the selected pumpkin seeds and buckwheat are placed in a container filled with clear water to remove the dirt on the surface, and washed repeatedly three times;

[0063] Then, prepare pumpkin seed pulp: peel the washed pumpkin seeds, soak them in warm water at 40°C for 3 hours, then transfer the pumpkin seeds to a juice extractor, add 98 parts of water to make a slurry, and filter after standing for 5 hours to obtain pumpkin seed paste;

[0064] Next, prepare buckwheat pulp: soak the buckwheat in warm water at 40°C for 3 hours, then transfer the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com