Energy-saving distilled water machine of gas-fired boiler

A technology of distilled water machines and gas boilers, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., capable of solving problems such as heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

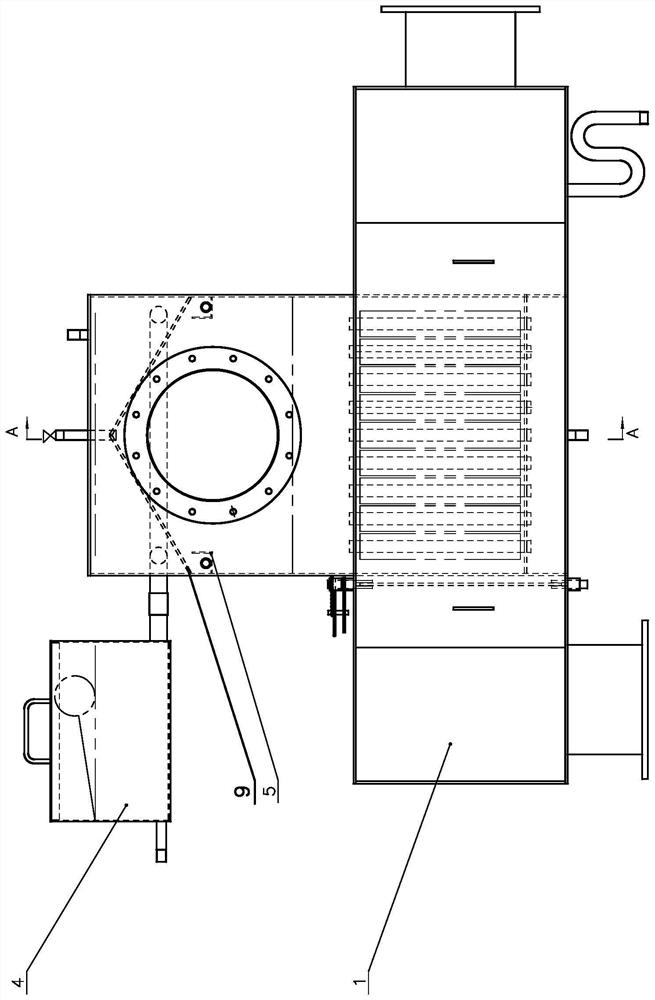

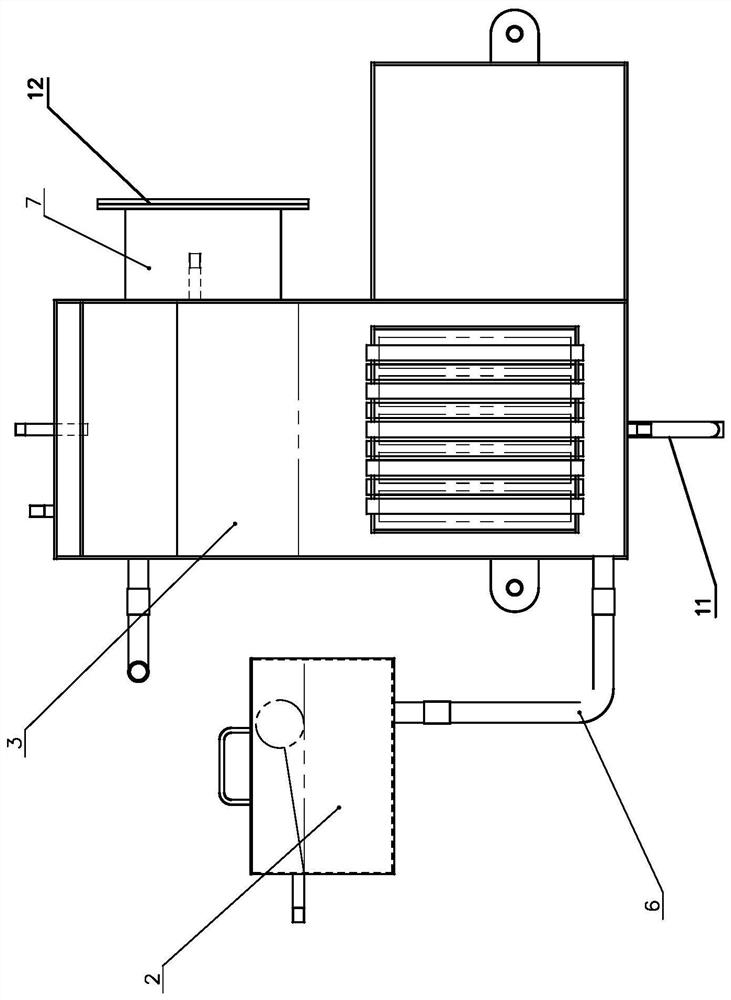

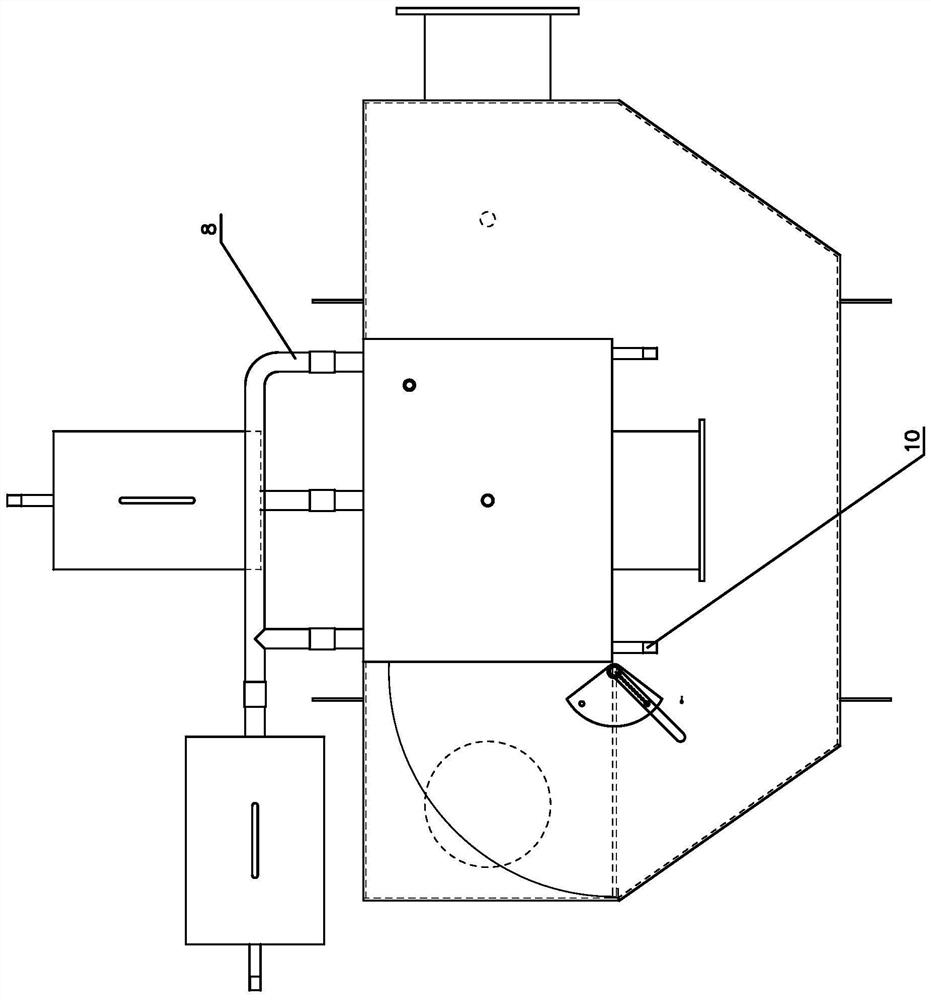

[0023] Embodiment 1: an energy-saving distilled water machine for a gas boiler, which includes a tail flue guide device 1, a tap water replenishment device 2; a distilled water device 3 and a condensed water discharge device 4;

[0024] The bottom of one end of the tail flue guide 1 is provided with a smoke inlet, and the side of the other end of the tail flue guide 1 is provided with a smoke outlet; the lower part of the distilled water device 3 is arranged in the middle of the tail flue guide 1, The bottom of the distilled water device 3 is provided with a heat exchange tube, the inlet end of the heat exchange tube communicates with the flue gas inflow direction of the tail flue guide device 1, and the outlet end of the heat exchange tube communicates with the flue gas flow out direction of the tail flue guide device 1; The tap water replenishment device 2 is connected to the bottom of the distilled water device 3 through a connecting pipe 6; the condensed water discharge dev...

specific Embodiment approach 2

[0026] Embodiment 2: The section of the distilled water collecting and diverting plate 5 is L-shaped.

[0027] Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0028] Embodiment 3: The cross-section in the horizontal direction of the tail flue guide device 1 is U-shaped, and the distilled water device 3 is arranged at the gap of the U-shape.

[0029] Other implementation manners are the same as the specific implementation manner 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com