Resistance device for steel pipe pile

A technology of resistance device and steel pipe pile, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of unfavorable vertical bearing capacity of steel pipe pile, heavy welding workload, and prone to hammering, etc., to avoid The effect of material cost and on-site workload, less structural consumables, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

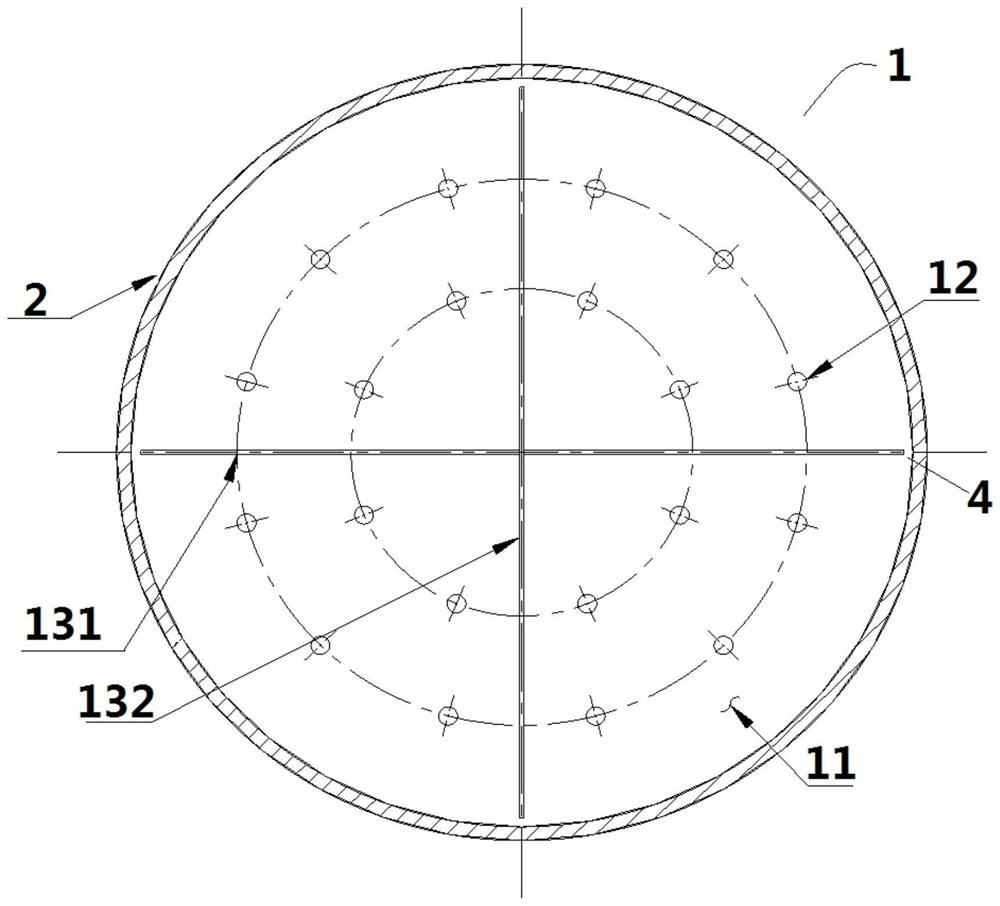

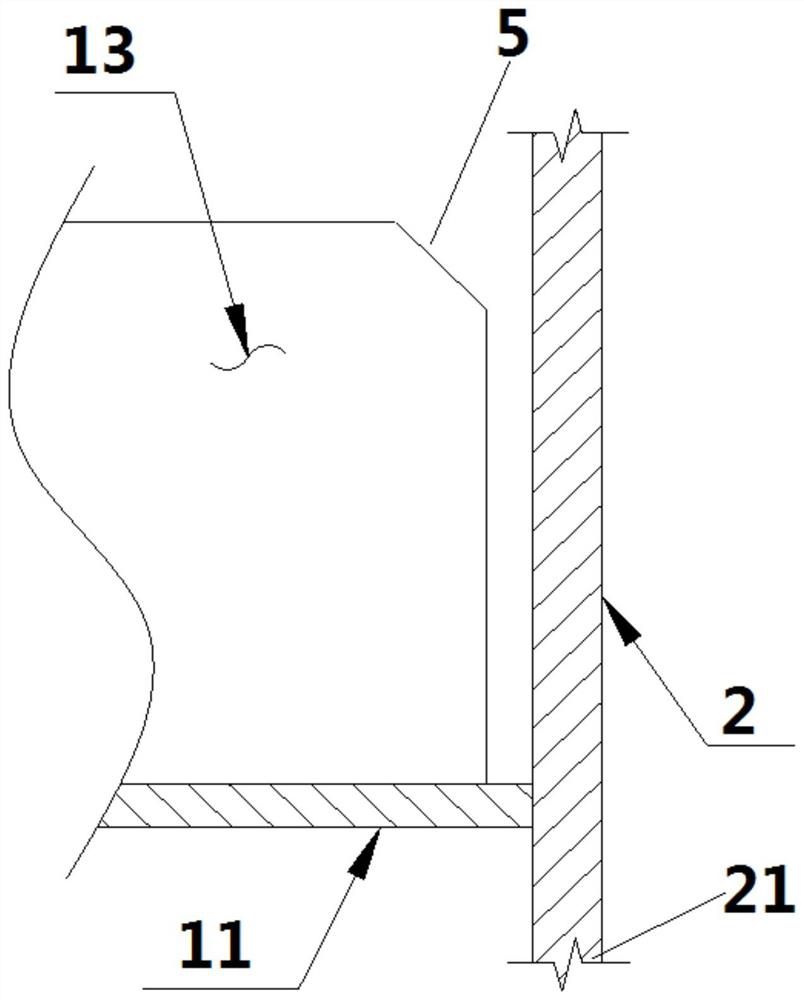

[0027] figure 1 is a schematic diagram of the installation of the resistance device for steel pipe piles of the present invention, figure 2 is a structural schematic diagram of the resistance device for steel pipe piles of the present invention, as figure 1 and figure 2 As shown, a resistance device 1 for a steel pipe pile 2 includes a circular sealing plate 11, the sealing plate 11 is fixed in the steel pipe pile 2, and is close to the pile end 21 of the steel pipe pile 2 driven into weak soil, and the sealing The plate 11 is perpendicular to the inner wall of the steel pipe pile 2. The diameter of the sealing plate 11 is equal to or close to the inner diameter of the steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com