Inner-engaged helical gear pair based on space conjugate curve

A technology of conjugate curves and helical gear pairs, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem of single contact form of internal meshing helical gear pairs that cannot meet the diverse needs of gear pairs and other problems, to achieve the effect of reducing the sliding rate, expanding the contact characteristics, and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

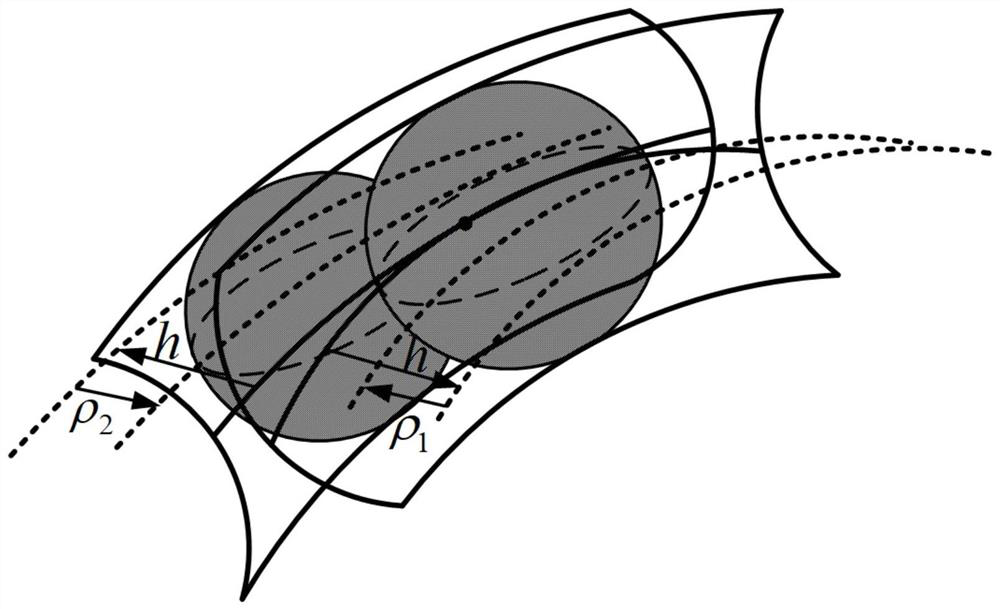

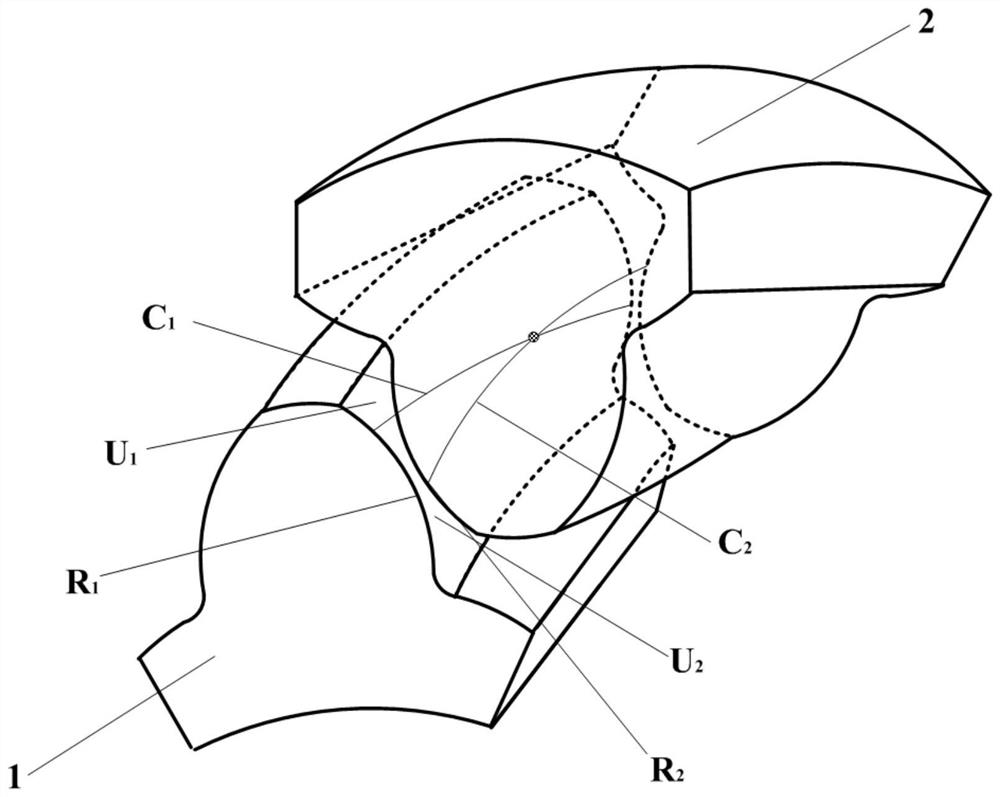

[0031] This embodiment provides an internal meshing helical gear pair based on space conjugate curves, including a pair of convex tooth pinion 1 and convex tooth internal gear 2 with convex tooth profile, the convex tooth pinion 1 and convex tooth The internal gears 2 are of helical gear structure and are in a point contact state during the meshing process; the tooth surface contact trace C of the convex pinion 1 1 Contact trace C with the tooth surface of the convex internal gear 2 2 are space conjugate curves.

[0032] Tooth surface contact trace C of convex pinion 1 1 Contact trace C with the tooth surface of the convex internal gear 2 2 , There are various forms of tooth surface contact traces, and appropriate line types can be provided according to design requirements to meet specific meshing conditions.

[0033] The tooth surface contact trace C of the convex tooth pinion 1 1 The general expression of is:

[0034]

[0035] Among them, t is a space arbitrary curve...

Embodiment 2

[0047] This embodiment provides an internal meshing helical gear pair based on space conjugate curves, including a pair of convex tooth pinion 1 with convex tooth profile and convex tooth internal gear 2, the convex tooth pinion 1 and convex tooth The internal gears 2 are of helical gear structure and are in a point contact state during the meshing process; the tooth surface contact trace C of the convex pinion 1 1 Contact trace C with the tooth surface of the convex internal gear 2 2 are space conjugate curves.

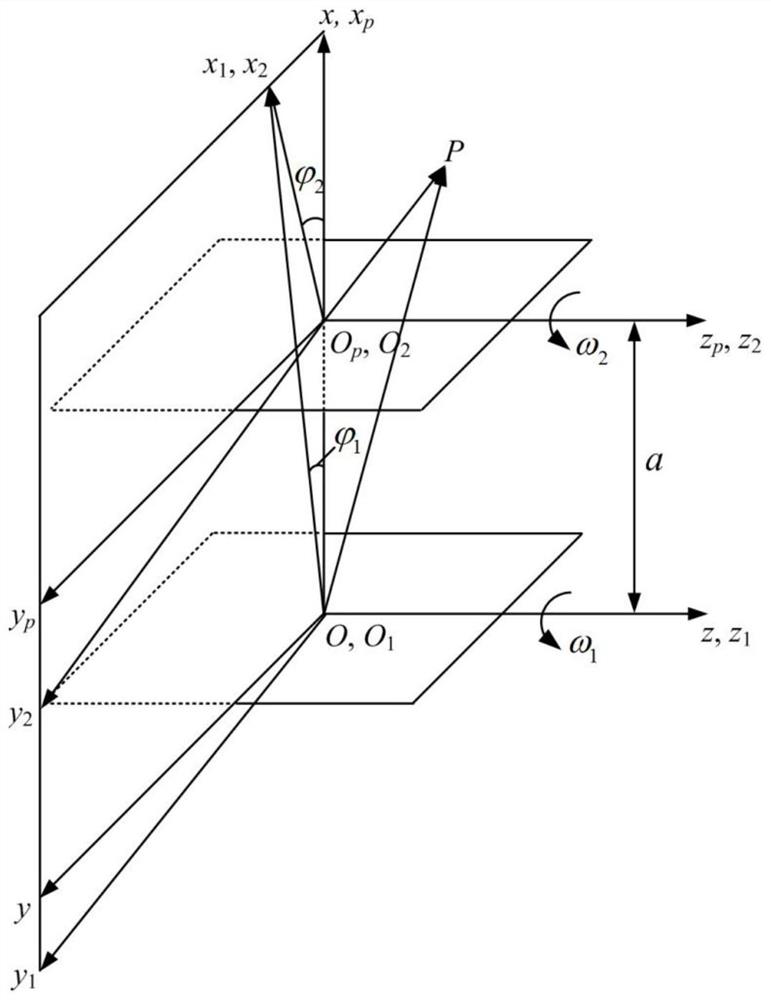

[0048] Such as figure 1 As shown, establish the space coordinate system of the internal meshing helical gear pair based on the space conjugate curve, where S(O-x,y,z) and S p (O p -x p ,y p ,z p ) is a space fixed coordinate system, S 1 (O 1 -x 1 ,y 1 ,z 1 ) and S 2 (O 2 -x 2 ,y 2 ,z 2 ) is the moving coordinate system fixedly connected with the convex pinion 1 and the convex internal gear 2 respectively. ω 1 and ω 2 are the rotational angular velo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com