Method for improving ohmic contact of ZnO film

An ohmic contact, thin film technology, applied in lasers, electrical components, circuits, etc., can solve the problems of complex process and unstable performance of ZnO devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

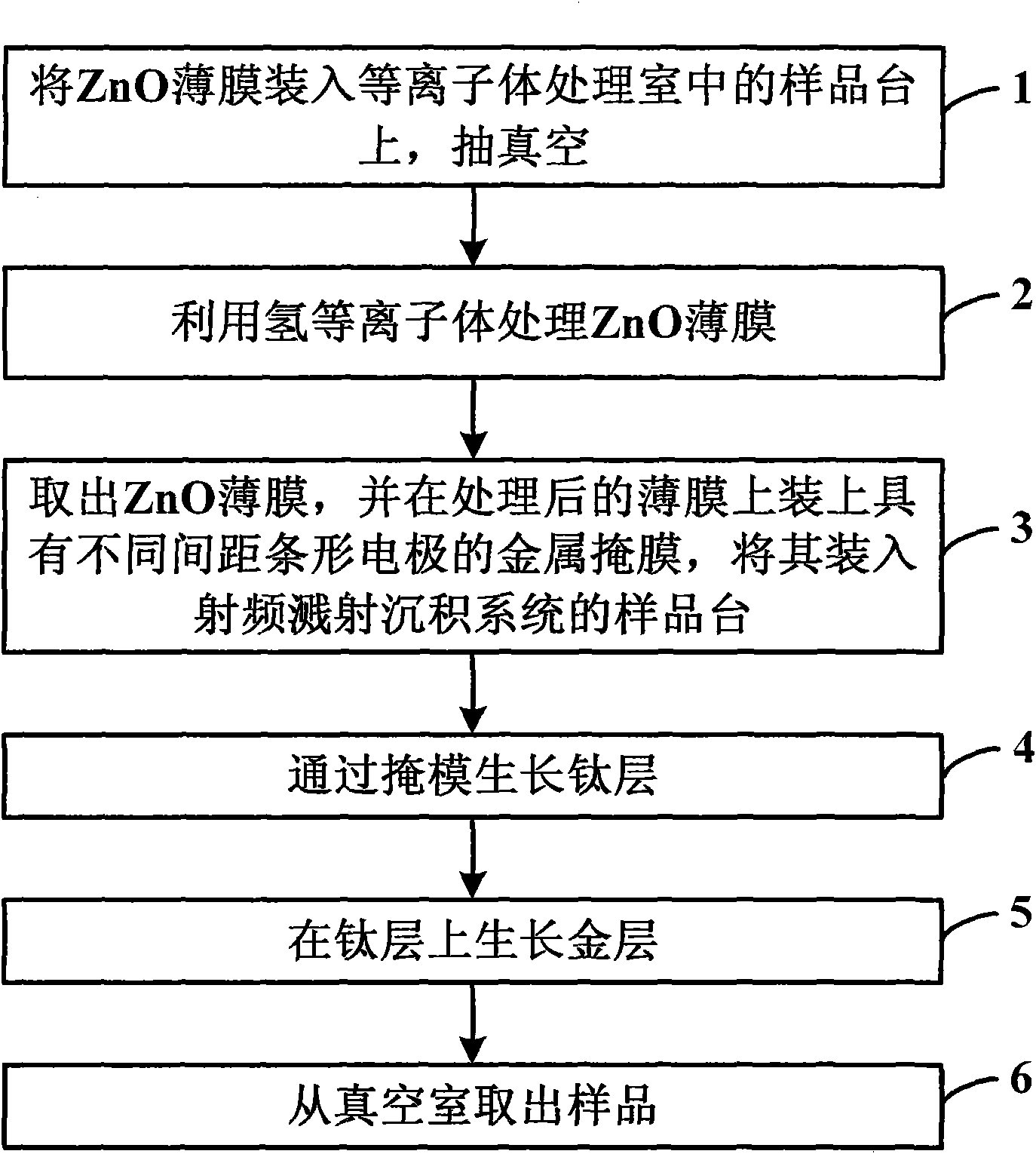

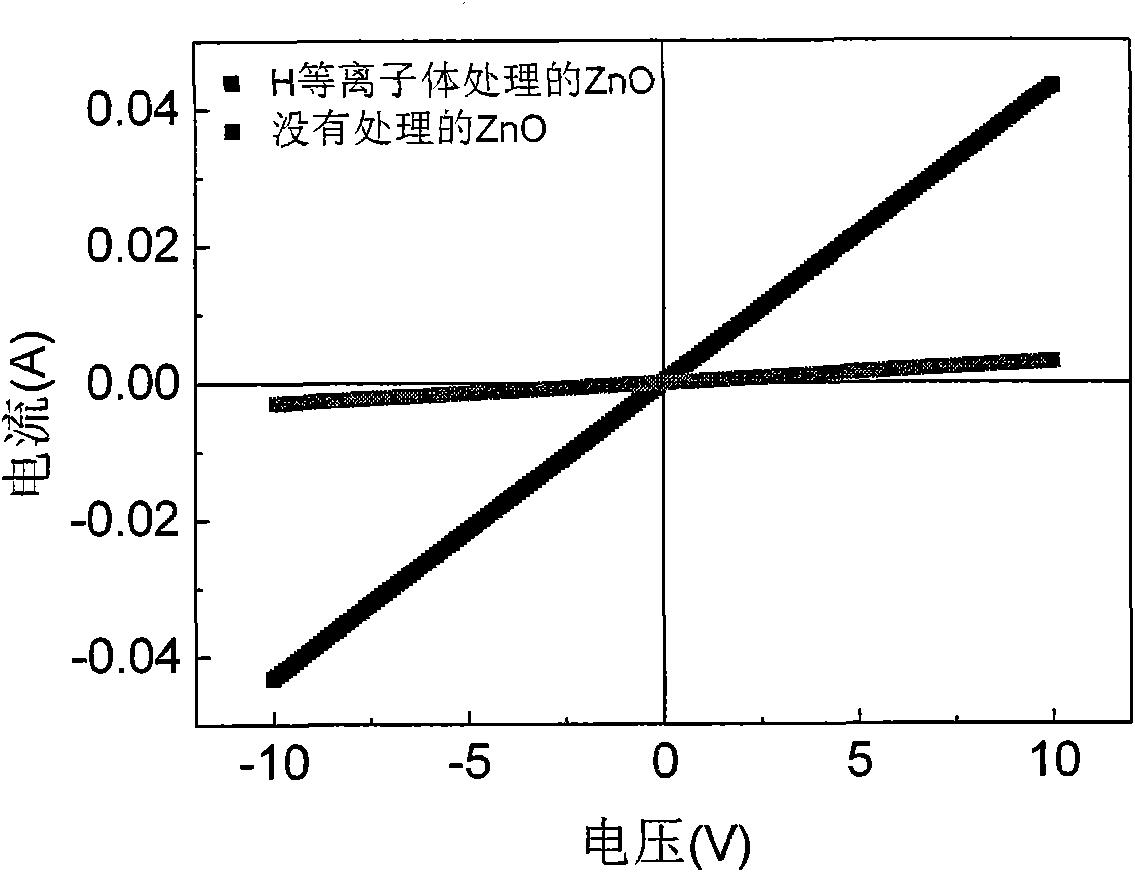

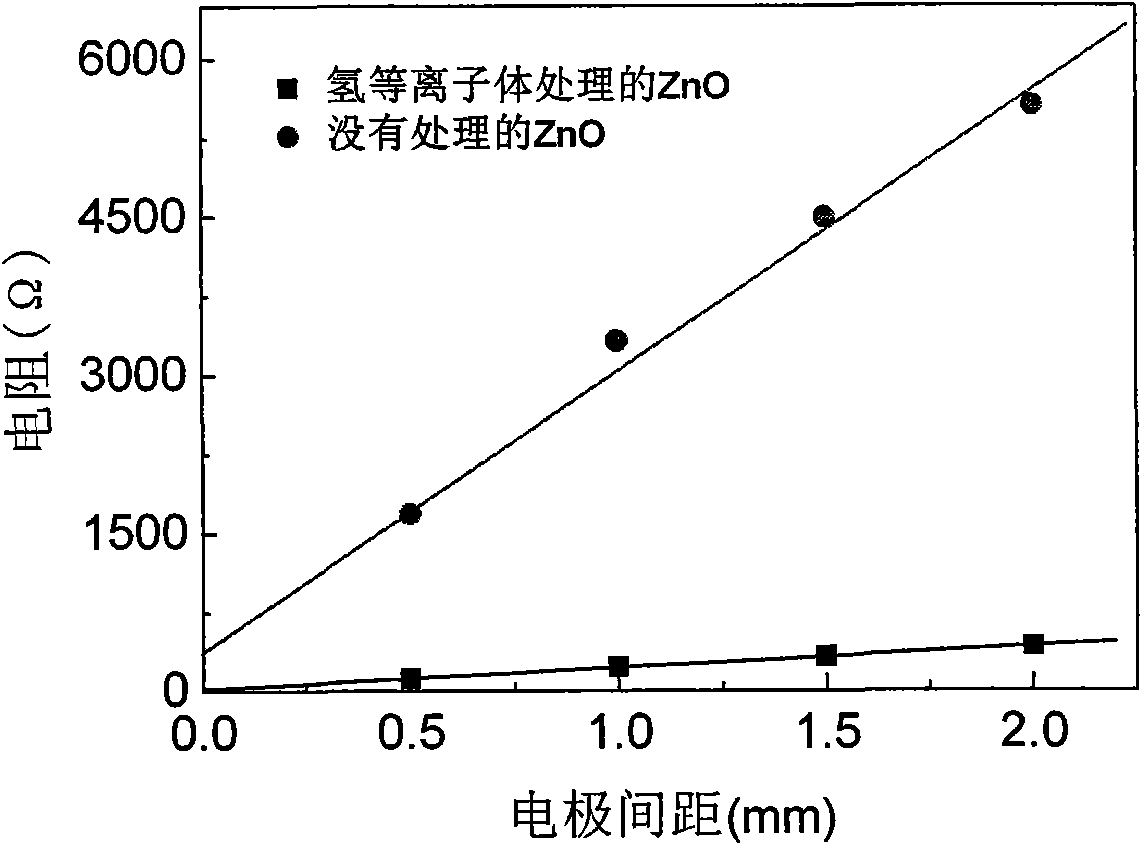

[0023] The first-principle calculations show that the role of hydrogen in ZnO is very different from that of hydrogen in other semiconductors. Hydrogen acts as a recombination center in general semiconductors to neutralize the dominant carriers. However, hydrogen in ZnO It exists as a shallow donor energy level and can have a high concentration. The non-intentionally doped ZnO is n-type. Use hydrogen plasma to treat the ZnO film through a metal mask, so that hydrogen can enter the ZnO film, which can act as a donor in the ZnO film, thereby improving the current-carrying area between the ZnO film and the metal contact area. sub-concentration. Due to the increase of the carrier concentration in the contact area of the ZnO film, the width of the ZnO barrier region becomes very thin, and the electrons pass through the barrier through the tunneling effect to generate a considerable tunneling current, so that its contact resistance can be very small, making the gap between the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com