Method for increasing flue gas temperature of semi-closed submerged arc furnace

A technology of flue gas temperature and submerged arc furnace, which is applied to furnaces, furnace components, furnace control devices, etc., can solve the problems of excessive cold air, uneven pressure in the furnace, electrode stab fire, etc., so as to increase the flue gas temperature and reduce the Consume, reduce contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

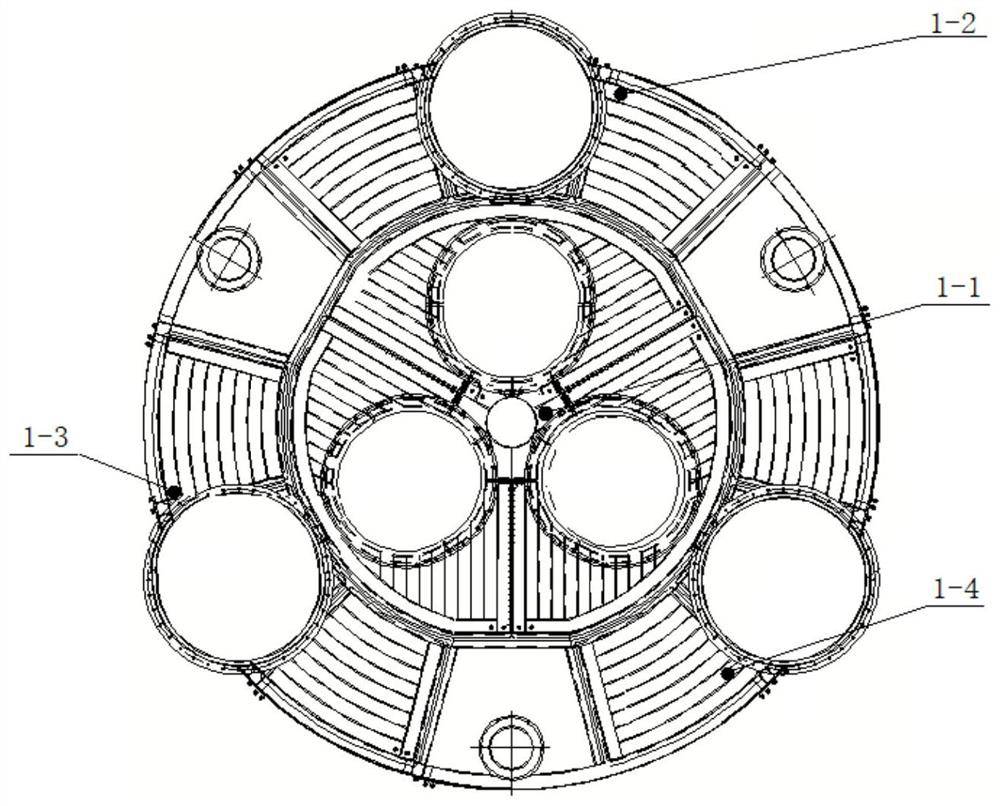

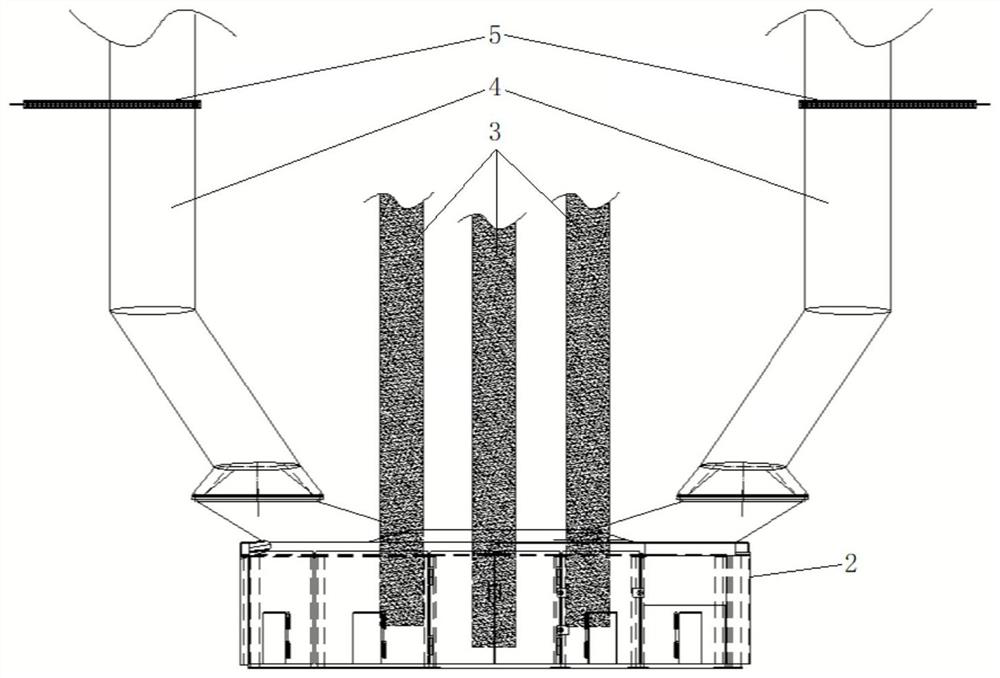

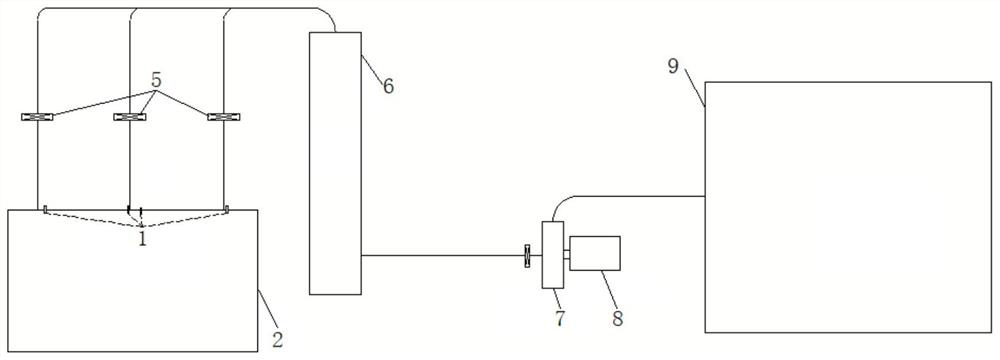

[0027] Embodiment one: if Figure 1 to Figure 3 As shown, a method for increasing the flue gas temperature of a semi-closed submerged arc furnace. The semi-closed submerged arc furnace includes a fume hood 2, an electrode 3, a chimney 4, a chimney opening rate regulating valve 5, a pressure sensor 1, and a flue gas waste heat recovery and utilization device 6. The induced draft fan 7, the induced draft fan frequency converter 8, the controller, the smoke hood 2 includes the feeding port and the furnace operation door, the chimney 4 is connected with the smoke hood 2, the electrode 3 penetrates the smoke hood 2 and forms a triangular area of the electric furnace. The charging port on the cover 2, the furnace operation door, the chimney 4 inlet, and the electric furnace triangular area are arranged with a pressure sensor 1, and a chimney opening rate regulating valve 5 is installed in the chimney 4. Among them, No. 1 furnace pressure detection point 1-1 is arranged in the tria...

Embodiment 2

[0034] Embodiment 2: On the basis of Embodiment 1, set the furnace pressure reference value P 0 ∈ΔP,P 0 Generally -10Pa.

[0035] In order to make the furnace pressure close to P 0 , when the pressure value acquired by pressure sensor 1 deviates from P 0 , if the pressure value cannot return to P within the set time 0 , automatically adjust the frequency of the induced draft fan inverter 8 again, and adjust the pressure in the furnace again; when the obtained pressure value returns to P 0 , the frequency of the frequency converter 8 of the induced draft fan is automatically adjusted again to reduce the pressure change in the furnace.

Embodiment 3

[0036] Embodiment 3: On the basis of any one of Embodiment 1 to Embodiment 2, when the pressure value obtained by pressure sensor 1 rises to higher than P in a short time max , it is considered as a large collapse, and the controller accumulates the number of collapses once. The obtained number of collapses can be used as one of the basis for judging the furnace condition and provide necessary reference for the operator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com