Low current, high power laser diode bar

A laser diode, high-power technology, used in lasers, laser devices, semiconductor lasers, etc., can solve problems such as reducing device performance and efficiency, and achieve the effects of reducing resistance, reducing current requirements, Joule heating, and reducing series resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

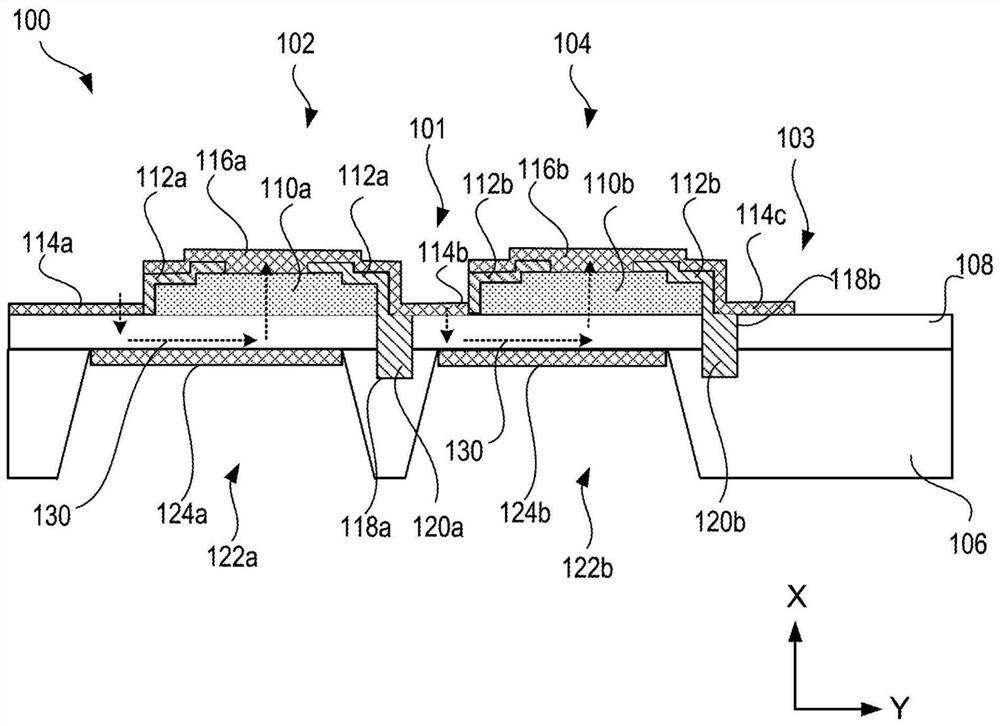

[0025] The ever-increasing drive currents for high power laser diode bars are due, at least in part, to their configuration in which the individual laser diodes within the laser diode bars are electrically connected in parallel with each other. Considering that the total laser diode bar drive current corresponds to the sum of the drive currents on each individual diode, the increasing number of individual diodes within the bar then adds to the total current. Similarly, as the current drive capability of the individual diodes increases, the maximum total current of the laser diode bars also increases.

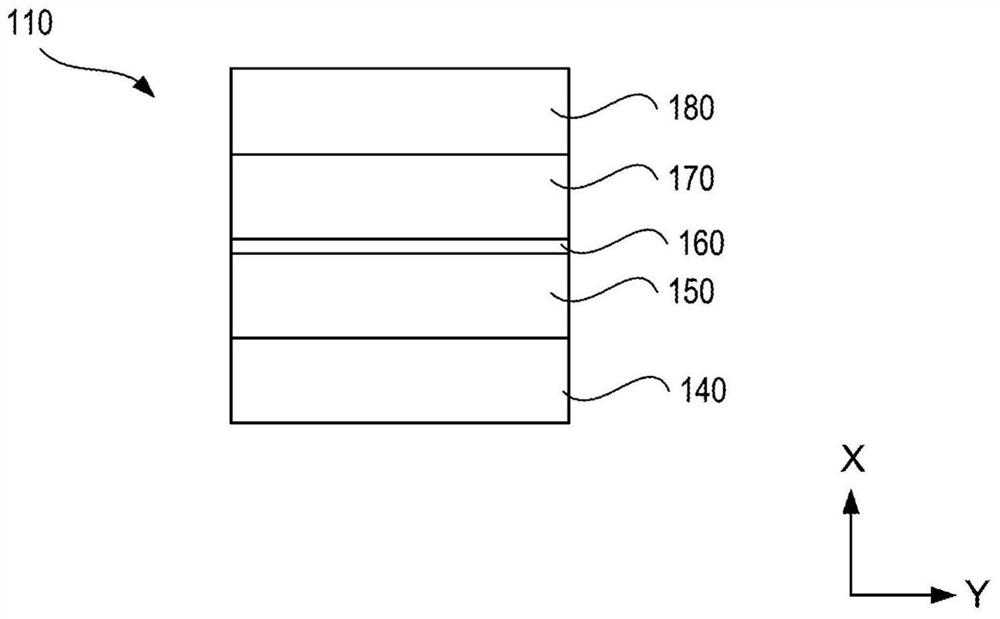

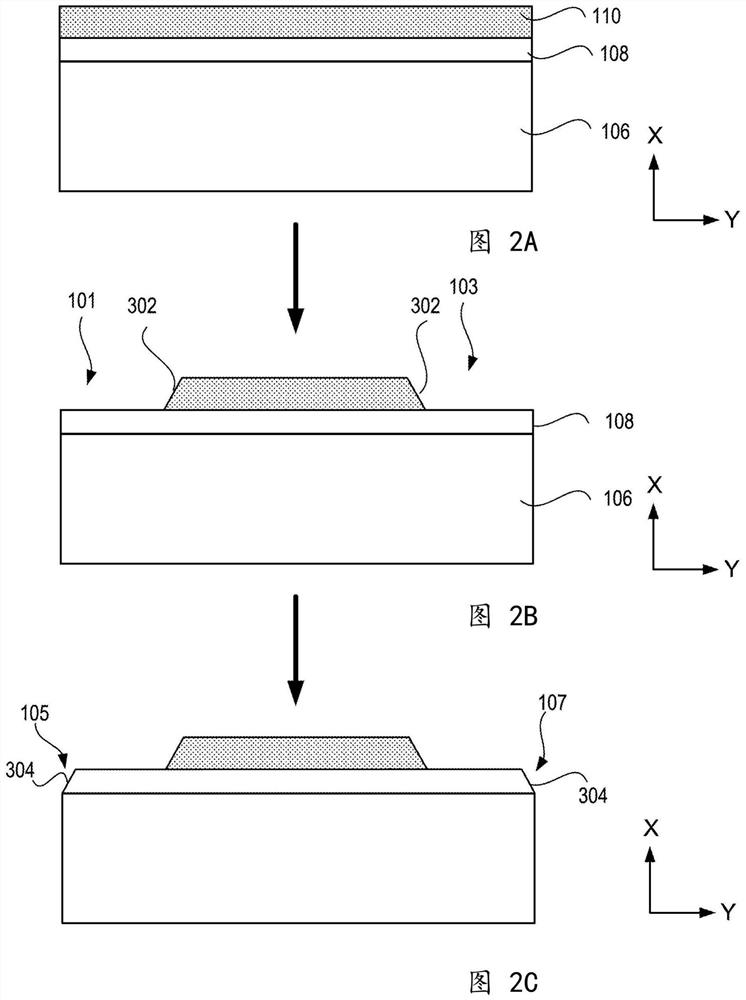

[0026]The present disclosure is directed to a laser diode bar configuration that facilitates a reduction in overall current by connecting individual laser diodes in series. In a series configuration, the drive current of the entire laser diode bar is limited by the laser diode within the bar with the smallest current drive capability. Thus, a substantial reduction in the maximu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com