Method for preparing metal fiber felt through resistance sintering, metal fiber felt and application of metal fiber felt

A metal fiber felt and metal fiber technology, which can be used in circuits, fuel cells, electrical components, etc., and can solve the problems of high energy consumption, long sintering time, and expensive equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

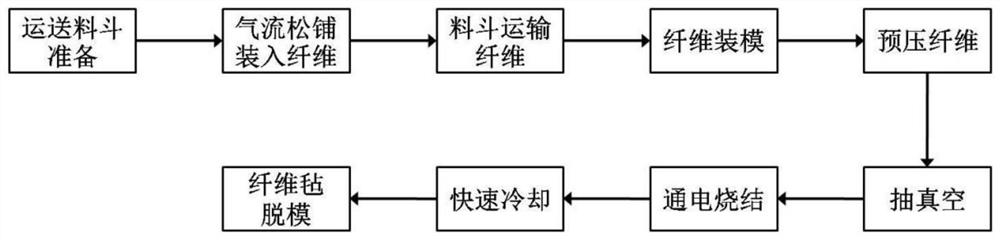

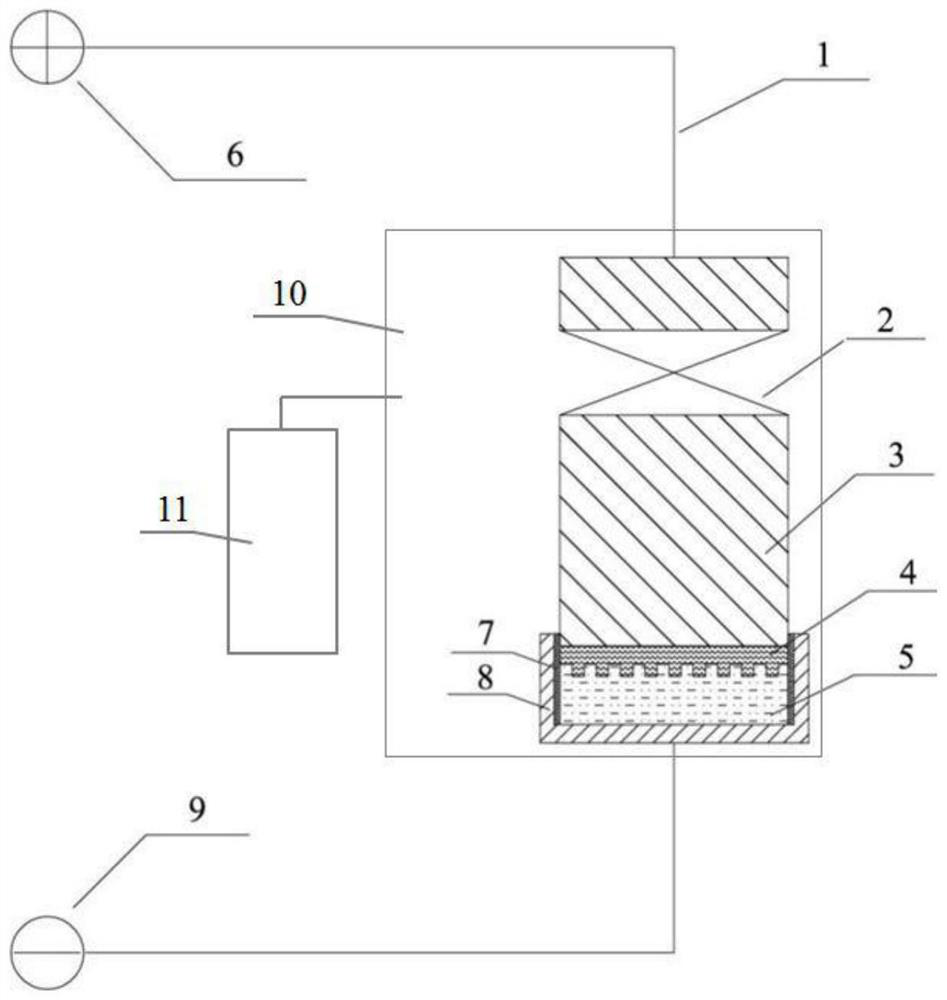

[0042] In this embodiment, the flow chart of the method for preparing metal fiber felt by step-by-step resistance sintering is as follows figure 1 As shown, the schematic diagram of the structure of the resistance sintering furnace is shown in figure 2 shown.

[0043] The iron-chromium-aluminum cutting fiber with a length of 15mm and a diameter of 22μm is loosely laid in the hopper through an air felting machine. The cross-sectional size of the hopper is 70×70mm, and the thickness of the loosely laid metal fiber is 16mm. The hopper is transported through the slideway To the top of the mold, turn on the switch at the bottom of the hopper so that the iron-chromium-aluminum fiber in the hopper falls into the mold. The mold is made of hard graphite material, the specification is 73×73×400mm (length×width×height), and the embedded thickness of the side mold is 3mm Al 2 o 3 Insulating ceramics, open the hydraulic device to make the conductive sheet contact with the fiber and mai...

Embodiment 2

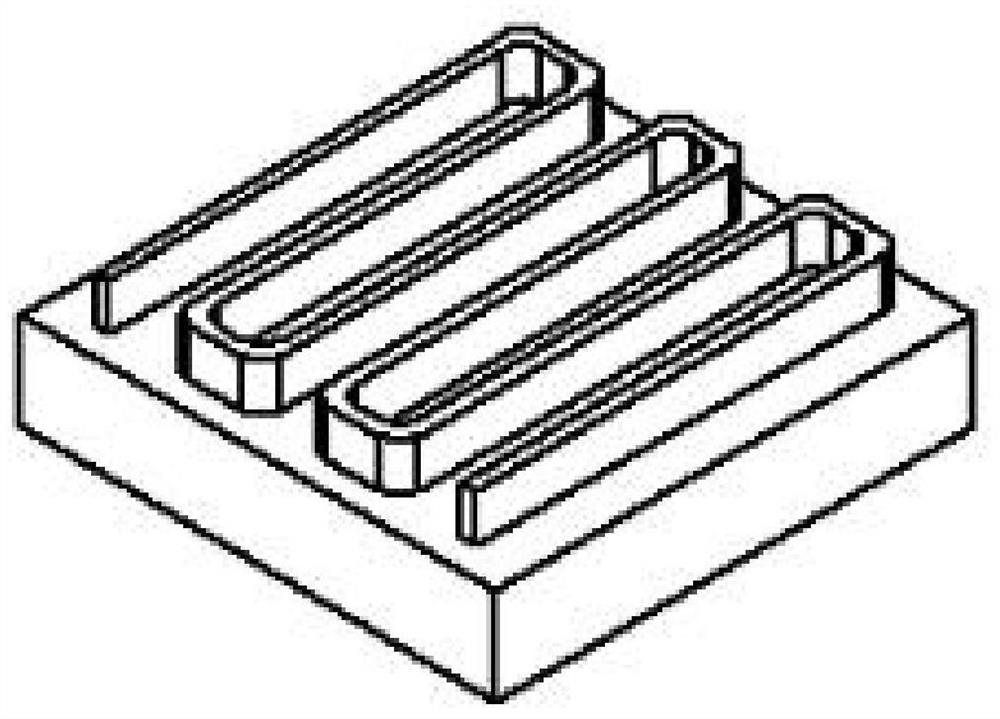

[0045] In this embodiment, the flow chart of the method for preparing metal fiber felt by step-by-step resistance sintering is as follows figure 1 As shown, the schematic diagram of the structure of the resistance sintering furnace is shown in figure 2 As shown, the schematic diagram of the flow channel of the conductive sheet is shown in image 3 shown.

[0046] The 316L stainless steel bundled drawn fibers with a length of 15mm and a diameter of 22μm are loosely laid in the hopper through an air felt machine. The cross-sectional size of the hopper is 70×70mm, and the thickness of the fiber is 16mm each time. Loosely spread the fibers. After the first and second loosely laid fibers are loaded into the hopper, graphite separators with specifications of 70×70×10mm (length×width×height) are placed respectively. After the third layer of fiber is loosely laid, graphite separators are not required. Plate, the lower surface of the graphite separator is provided with a serpentine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com