A method of instantaneous liquid phase diffusion bonding for reliable joints of rafm steel

A diffusion connection, instantaneous liquid phase technology, applied in welding/welding/cutting items, welding equipment, manufacturing tools, etc., can solve the problems of large residual stress of joints, workpiece deformation, and high surface roughness of the workpiece connection surface, and achieve the connection time. Short, small deformation of workpiece, low pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1: Cut RAFM steel into The cylinder, and then use a grinder to grind the end face of the cylinder flat and fine.

[0022] Step 2: Cut the Fe-Si-B alloy foil into For the disc, use sandpaper to polish both sides of the foil to 1500#. Step 3: Before connecting, ultrasonically clean the sample and alloy foil in acetone for 20 minutes, dry them, and then ultrasonically clean them in alcohol for 30 minutes, and dry them. Then the surface of the sample was washed with a pickling solution (volume percentage 20% HNO 3 +5%HF+75%H 2 O) wash 3min.

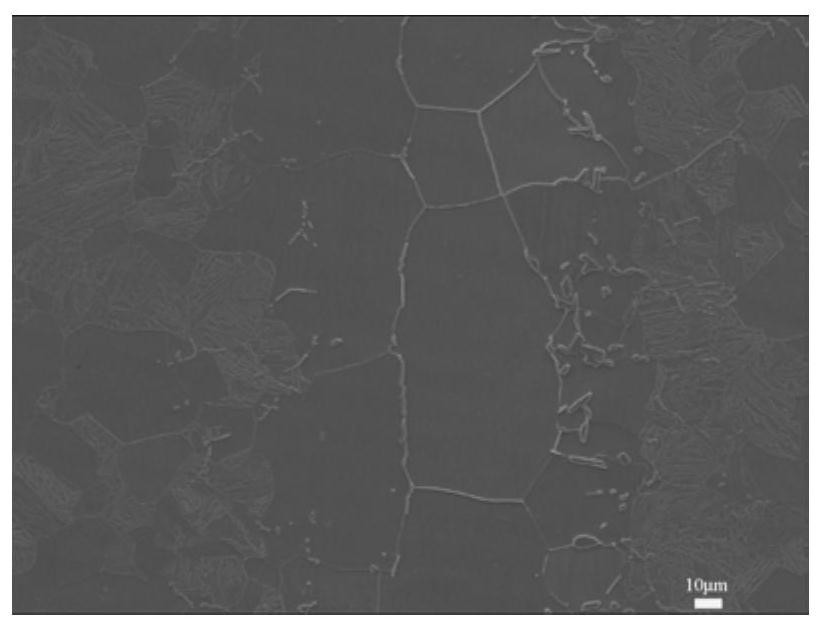

[0023] Step 4: sandwich the Fe-Si-B alloy foil between the surfaces to be connected of two RAFM steel samples. Place the assembled sample in a vacuum furnace and draw a vacuum. When the vacuum reaches 5×10 -3 Start heating at Pa, raise the temperature to 850°C at a heating rate of 5°C / min, hold for 30 minutes, then raise the temperature to 1215°C at a heating rate of 5°C / min, apply a pressure of 1MPa and hold for 3 minute...

Embodiment 2

[0028] Step 1: Cut RAFM steel into The cylinder, and then use a grinder to grind the end face of the cylinder flat and fine.

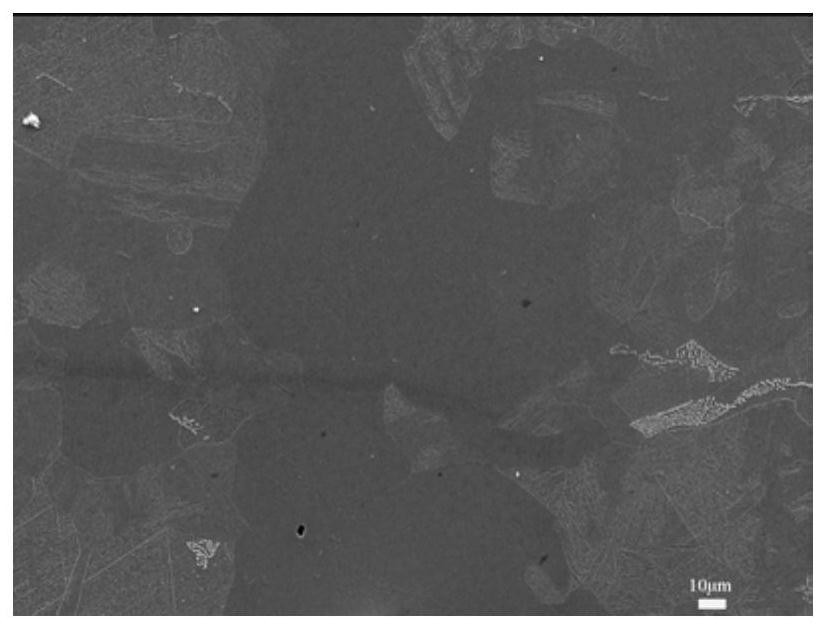

[0029] Step 2: Cut the Fe-Si-B alloy foil into For the disc, use sandpaper to polish both sides of the foil to 1500#. Step 3: Before connecting, ultrasonically clean the sample and alloy foil in acetone for 20 minutes, dry them, and then ultrasonically clean them in alcohol for 30 minutes, and dry them. Then the surface of the sample was washed with pickling solution (20% HNO 3 +5%HF+75%H 2 O) wash 5min. Step 4: sandwich the Fe-Si-B alloy foil between the surfaces to be connected of two RAFM steel samples. Place the assembled sample in a vacuum furnace and draw a vacuum. When the vacuum reaches 5×10 -3 Start heating at Pa, raise the temperature to 900°C at a heating rate of 10°C / min, keep it for 20 minutes, then raise the temperature to 1200°C at a heating rate of 10°C / min, apply a pressure of 0.8MPa and keep it for 30 minutes, then cool to ro...

Embodiment 3

[0034] Step 1: Cut RAFM steel into The cylinder, and then use a grinder to grind the end face of the cylinder flat and fine.

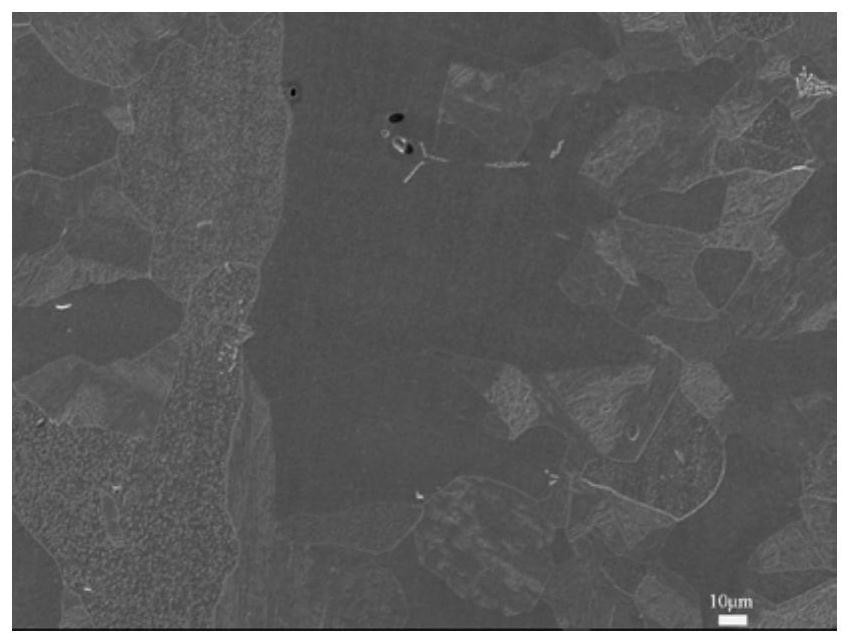

[0035] Step 2: Cut the Fe-Si-B alloy foil into For the disc, use sandpaper to polish both sides of the foil to 1500#. Step 3: Before connecting, ultrasonically clean the sample and amorphous foil in acetone for 30 minutes, dry them, and then ultrasonically clean them in alcohol for 20 minutes, and dry them. Then the surface of the sample was washed with pickling solution (20% HNO 3 +5%HF+75%H 2 O) wash 3min. Step 4: sandwich the Fe-Si-B alloy foil between the surfaces to be connected of two RAFM steel samples. Place the assembled sample in a vacuum furnace and draw a vacuum. When the vacuum reaches 5×10 -3 Start heating at Pa, raise the temperature to 850°C at a heating rate of 5°C / min, keep it for 30 minutes, then raise the temperature to 1200°C at a heating rate of 5°C / min, apply a pressure of 0.2MPa and keep it for 60 minutes, then cool to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com