Lithium-supplementing negative pole piece and lithium ion battery thereof

A lithium-ion battery and negative pole piece technology, which is applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems affecting the cycle life, energy density and kinetic performance of lithium-ion batteries, so as to improve the electrochemical performance, Increased energy density and the effect of alleviating heat problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] (1) Preparation of positive pole piece

[0044] The positive electrode active material LiNi 0.8 co 0.1 mn 0.1 o 2 , Conductive agent conductive carbon, and binder polyvinylidene fluoride (PVDF) are mixed at a mass ratio of 96:2:2, stirred under the action of a vacuum mixer until the system is uniform, and a lithium-ion battery cathode slurry with a certain viscosity is obtained ; The positive electrode slurry is evenly coated on both surfaces of the positive electrode current collector aluminum foil, cold pressed after drying at 85 ° C, and then edge trimmed, cut into pieces, slitting, and slitting under vacuum conditions and temperature Dry at 85°C for 4 hours, weld the lugs, and make the positive pole piece of lithium battery.

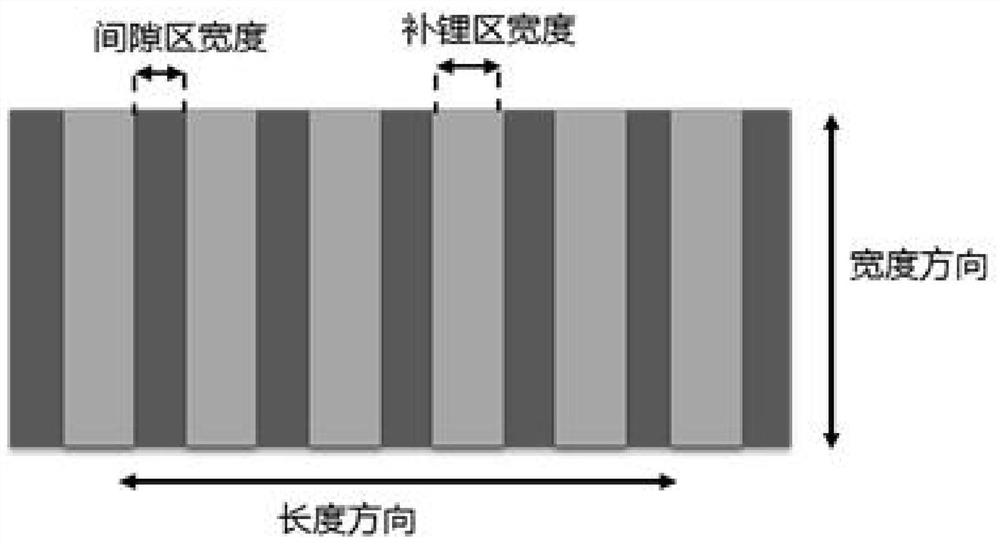

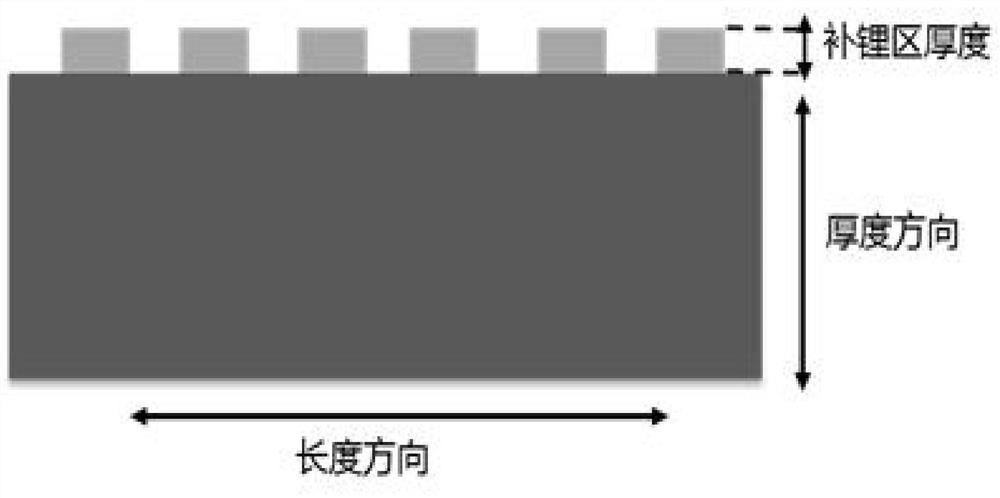

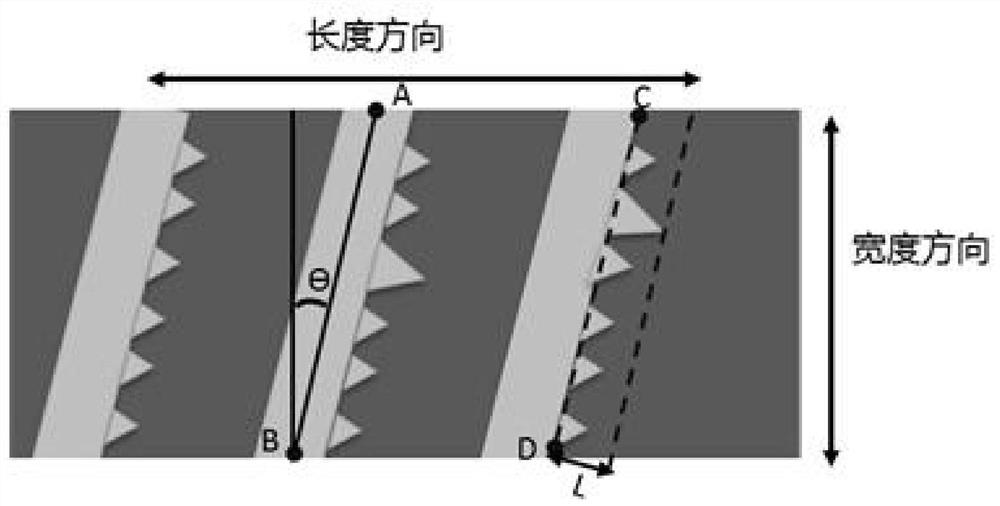

[0045] (2) Preparation of negative pole piece

[0046] The preparation method of the negative electrode sheet of Example 1-17 is: mix silicon oxide and artificial graphite according to the mass ratio of 3:7 to obtain the negative electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com