Method for assisting in forming composite material propeller blade by using air bag inflation

A technology of composite materials and propellers, applied in applications, household appliances, household components, etc., can solve the problems of long manufacturing cycle for repair or reprocessing, very high requirements for filling and mold matching, uneven heat conduction, etc., to reduce production costs And the effect of manufacturing cycle, avoiding core pressure loss or insufficient filling, and ensuring internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

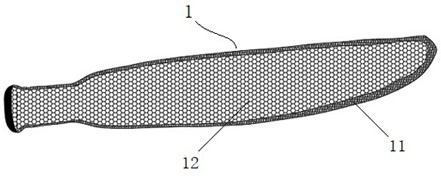

[0034] This embodiment is a method of utilizing airbag inflation to assist composite material propeller blade molding, and the structure of the composite material propeller blade 1 is as follows figure 1 As shown, it is formed by filling the inner core 12 of foam material inside the skin shell 11 of composite material, and its molding method includes the following steps:

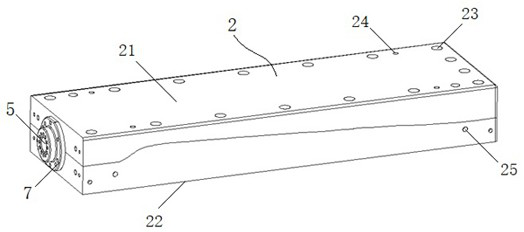

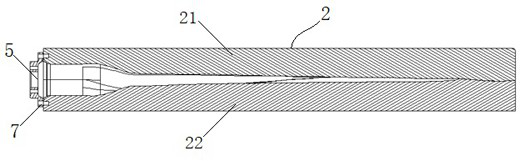

[0035] 1) Forming tool design: according to the shape of the propeller blade 1 prepared as required, design and process the metal forming tool 2 of the propeller blade 1 through mechanical processing, such as figure 2 and image 3 As shown; the metal forming tooling 2 of the propeller blade 1 includes an upper petal mold body 21 and a lower petal mold body 22 that can be matched to the mold; The mold inner cavity 20 formed matches the external profile of the propeller blade 1; the upper lobe mold body 21 and the lower lobe mold body 22 are also designed with positioning guide pin holes 23 and bolt holes 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com