Degradable environment-friendly antibacterial preservative film and preparation method thereof

A fresh-keeping film and environmental protection technology, applied in the field of degradable environmental protection antibacterial fresh-keeping film and its preparation, can solve the problems of not meeting the requirements of safety, health and ecological environmental protection, lack of degradability, poor mechanical properties, etc., and achieve excellent biodegradability, A wide range of sources and the effect of improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

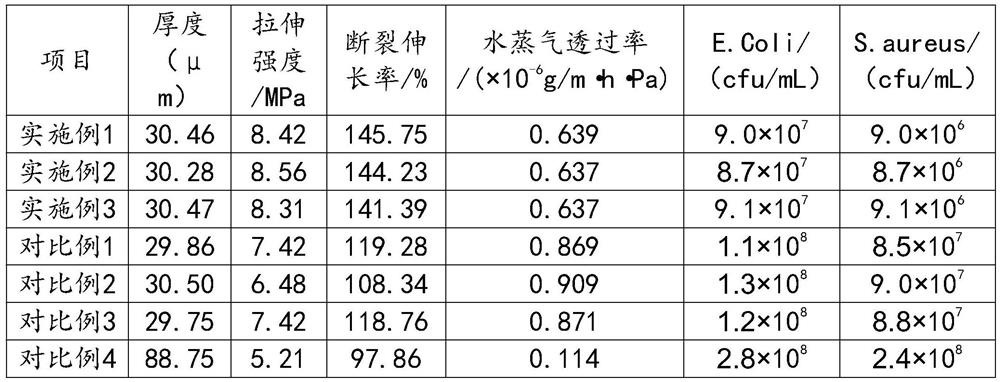

Examples

Embodiment 1

[0036] A degradable environment-friendly antibacterial fresh-keeping film, comprising the following raw materials by weight: 30 parts of polyvinyl alcohol, 5 parts of sweet potato starch, 5 parts of modified protein liquid, 1 part of compound essential oil emulsion, 8 parts of modified montmorillonite, and 1 part of glycerin part and 1 part of dispersant;

[0037] The degradable environmental protection antibacterial fresh-keeping film is made by the following steps:

[0038] The first step is to add polyvinyl alcohol and sweet potato starch into deionized water respectively to prepare a polyvinyl alcohol solution with a mass fraction of 5% and a sweet potato starch solution with a mass fraction of 5%. Heating, reacting for 15min under the condition of rotating speed 200r / min, then mixing in equal volume to obtain the first mixed solution;

[0039] The second step, add dispersant and modified montmorillonite to the first mixed solution, react for 5 minutes at a temperature of...

Embodiment 2

[0054] A degradable environment-friendly antibacterial fresh-keeping film, comprising the following raw materials by weight: 35 parts of polyvinyl alcohol, 6 parts of sweet potato starch, 8 parts of modified protein liquid, 2 parts of compound essential oil emulsion, 9 parts of modified montmorillonite, 2 parts of glycerin part and 1 part of dispersant;

[0055] The degradable environmental protection antibacterial fresh-keeping film is made by the following steps:

[0056] The first step is to add polyvinyl alcohol and sweet potato starch into deionized water respectively to prepare a polyvinyl alcohol solution with a mass fraction of 5% and a sweet potato starch solution with a mass fraction of 5%. Heating, reacting for 15min under the condition of rotating speed 250r / min, then mixing in equal volume to obtain the first mixed solution;

[0057] In the second step, add dispersant and modified montmorillonite to the first mixed solution, react for 8 minutes at a temperature o...

Embodiment 3

[0072] A degradable environment-friendly antibacterial fresh-keeping film, comprising the following raw materials by weight: 40 parts of polyvinyl alcohol, 10 parts of sweet potato starch, 10 parts of modified protein solution, 3 parts of compound essential oil emulsion, 10 parts of modified montmorillonite, and 3 parts of glycerin part and 1 part of dispersant;

[0073] The degradable environmental protection antibacterial fresh-keeping film is made by the following steps:

[0074]The first step is to add polyvinyl alcohol and sweet potato starch into deionized water respectively to prepare a polyvinyl alcohol solution with a mass fraction of 5% and a sweet potato starch solution with a mass fraction of 5%. Heating, reacting for 15min under the condition of rotating speed 300r / min, then mixing in equal volume to obtain the first mixed solution;

[0075] In the second step, add dispersant and modified montmorillonite to the first mixed solution, react for 10 minutes at a temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com