A kind of preparation technology of nickel-plated carbon fiber felt

A nickel-plated carbon fiber and preparation process technology, applied in the field of fiber products, can solve problems such as poor fiber effect and reduce fiber felt quality, and achieve the effects of improving felt quality, reducing knots and agglomeration, and improving dispersion uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

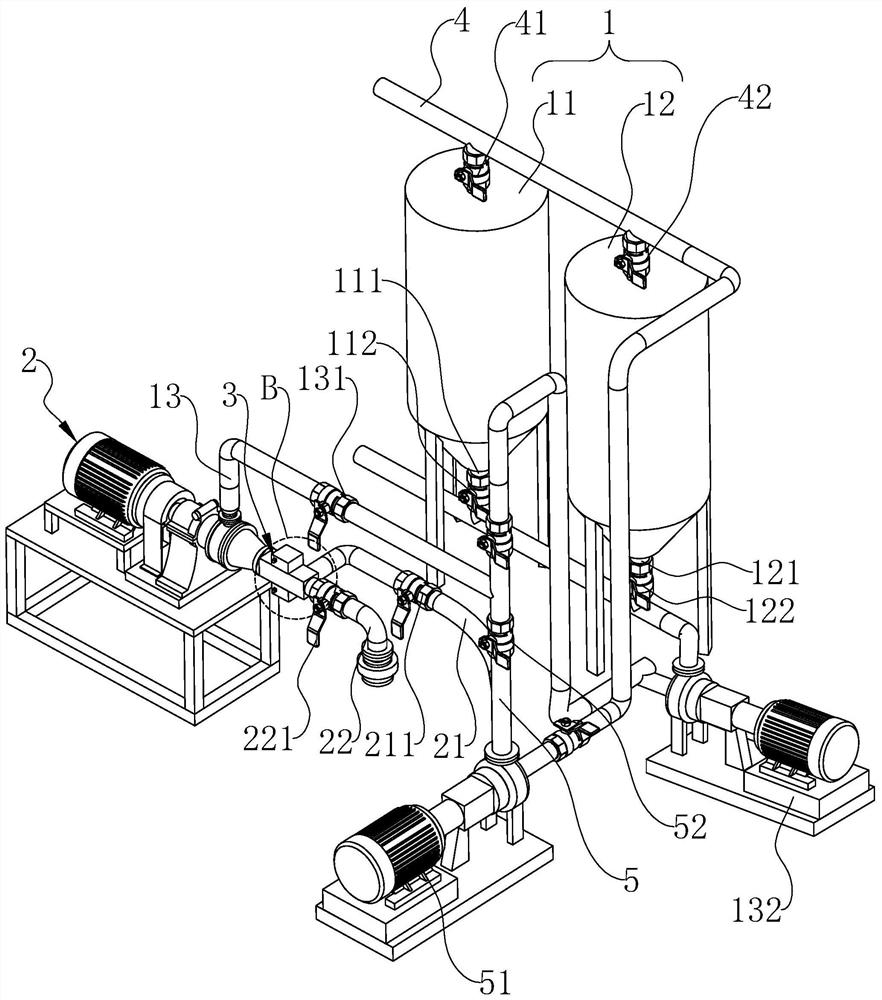

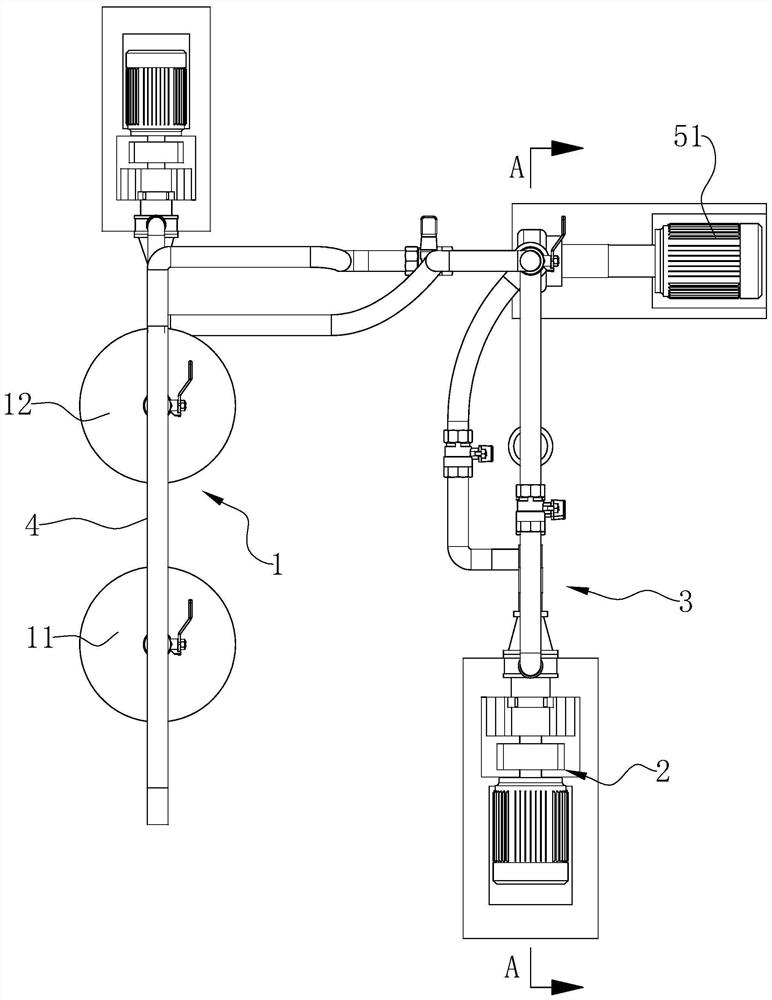

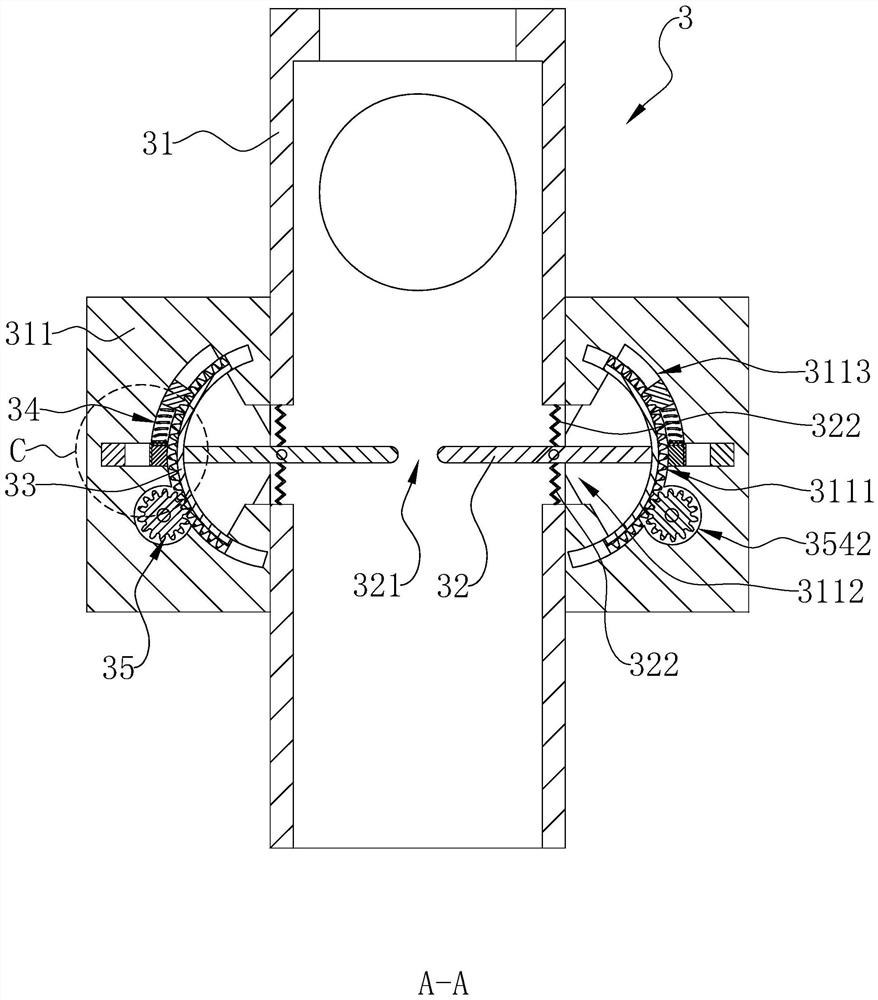

[0041] The following is attached Figure 1-5 The application is described in further detail.

[0042] The embodiment of the application discloses a double deflagging machine.

[0043] Such as figure 1 with figure 2 As shown, the double deflagging machine mainly includes a stirring and deflaking device 1 and a high-frequency deflaking device 2, wherein the high-frequency deflaking device 2 is a commercially available high-frequency deflaking device, and the stirring and deflaking device 1 includes a first stirring device 11 and a second stirring device 12 , the feeding ends of the first stirring device 11 and the second stirring device 12 are all connected with a main feed pipe 4, the fifth control valve 41 is connected between the first stirring device 11 and the main feed pipe 4, the second stirring device 12 A sixth control valve 42 is connected with the main feed pipe 4 . Open the fifth control valve 41 to feed into the first stirring device 11 , and open the sixth con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com