Automatic condensate water discharging device of onboard evaporator

An automatic discharge and evaporator technology, applied in evaporator/condenser, refrigerator, refrigeration components, etc., can solve problems such as difficulty in condensing water discharge, and achieve the effect of improving functional performance and increasing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

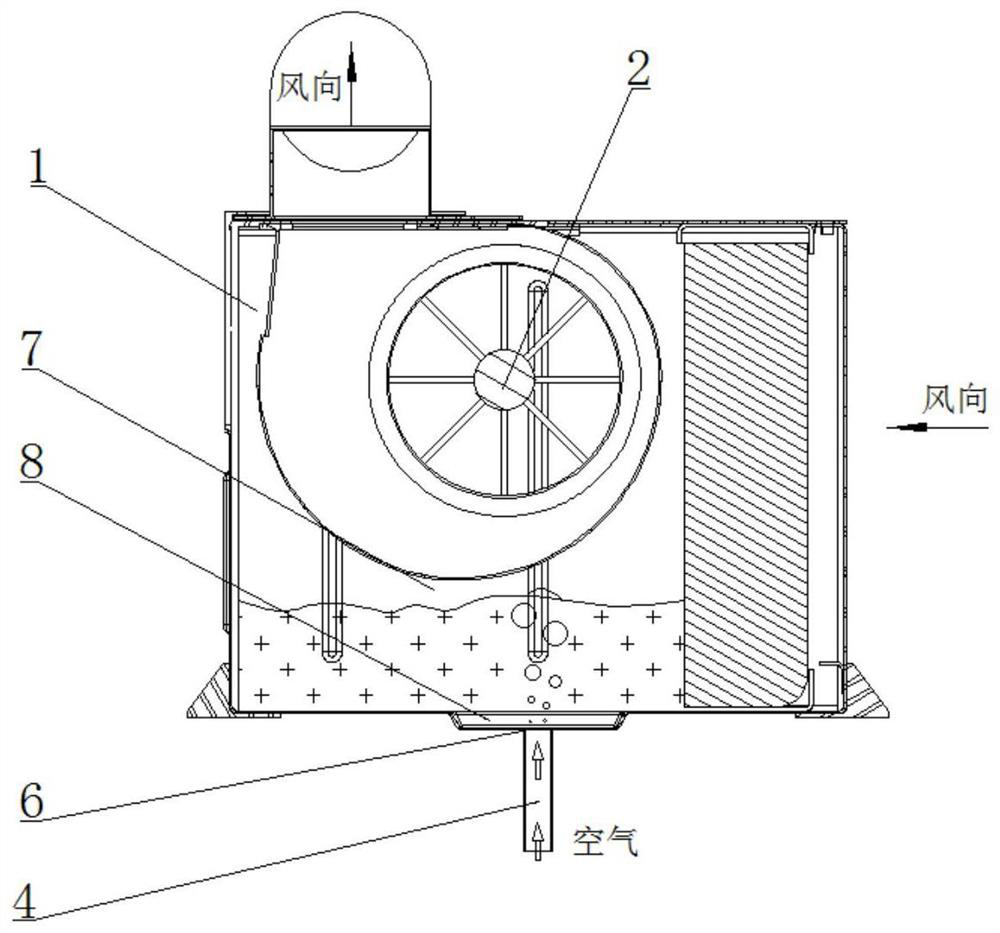

[0043] Embodiment 1, see attached figure 1 , 2, 5-8, providing an on-board evaporator condensate automatic discharge device, including an evaporator shell 1, an evaporating fan 2, a vent pipe 3, a drain pipe 4 and a valve body 5;

[0044] The evaporation fan is installed in the shell of the evaporator, which can form a negative pressure area 7 when drawing air; the lower part of the negative pressure device is a water storage pool 8;

[0045] The upper end of the ventilation pipe penetrates into the evaporator shell, and the upper end of the ventilation pipe is in a negative pressure area;

[0046] The water storage tank is provided with a water hole 6, and the upper end of the drainage pipe is connected to the water hole, and the water hole is in a negative pressure zone;

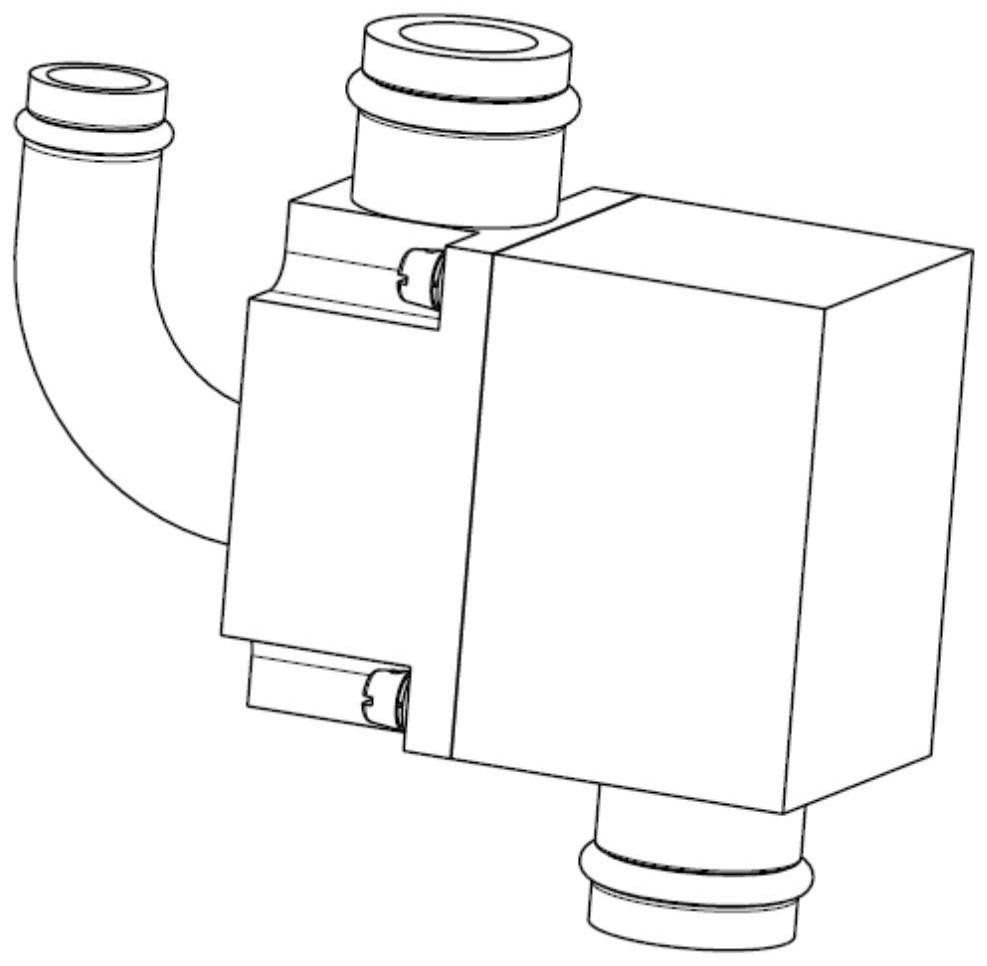

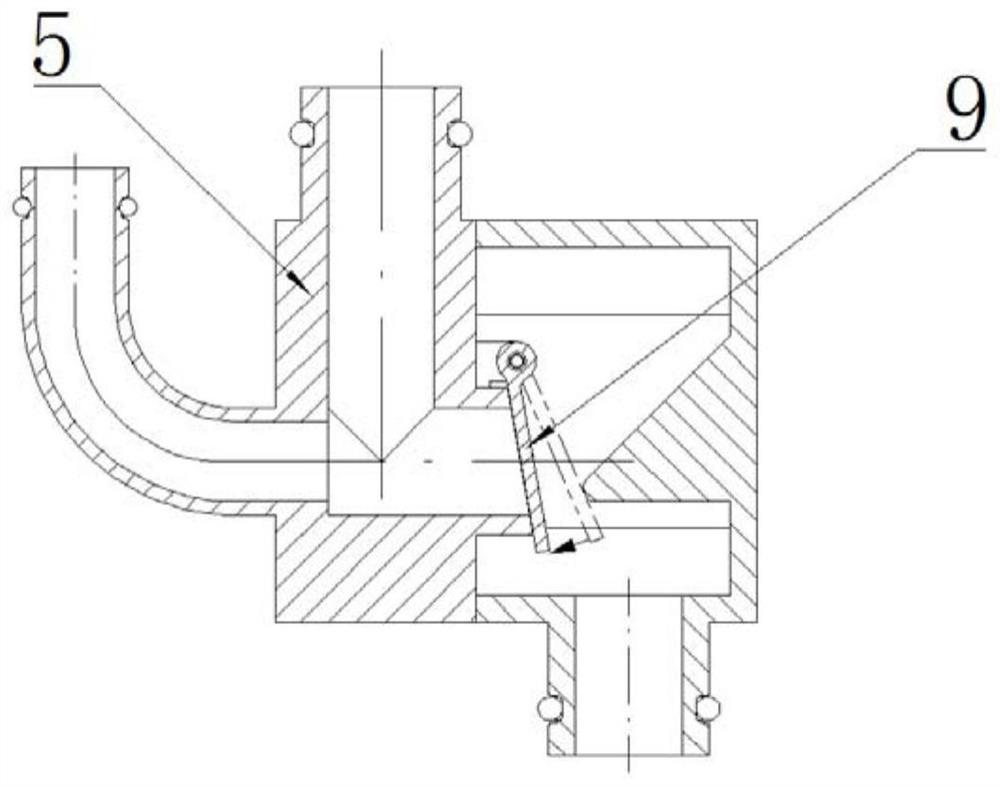

[0047] The valve body is provided with two upper nozzles and one lower nozzle, and the two upper nozzles and one lower nozzle communicate with the inner cavity of the valve to form a three-way structure, ...

Embodiment 2

[0053] Embodiment 2, see attached Figure 1-8 , providing an on-board evaporator condensate automatic discharge device, comprising an evaporator shell 1, an evaporator fan 2, a ventilation pipe 3, a drain pipe 4 and a valve body 5;

[0054] The evaporation fan is installed in the shell of the evaporator, which can form a negative pressure area 7 when drawing air; the lower part of the negative pressure device is a water storage pool 8;

[0055] The upper end of the ventilation pipe penetrates into the evaporator shell, and the upper end of the ventilation pipe is in a negative pressure area;

[0056] The water storage tank is provided with a water hole 6, and the upper end of the drainage pipe is connected to the water hole, and the water hole is in a negative pressure zone;

[0057] The valve body is provided with two upper nozzles and one lower nozzle, and the two upper nozzles and one lower nozzle communicate with the inner cavity of the valve to form a three-way structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com