Preparation method of heterogeneous anisotropic transparent rock-like material sample

An anisotropic, rock material technology, applied in the field of geotechnical engineering, which can solve the problems of limited quantity, high cost of rock CT scanning, and restricted use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a heterogeneous anisotropic transparent rock-like material sample, comprising the following steps:

[0037] (1) Material cleaning: first clean the transparent colorless fused silica sand and transparent colored glass sand with plasma water. After cleaning, put the fused silica sand and glass sand into a drying box, dry them at 60°C, and take them out. Remove impurities with tweezers;

[0038] (2) Material weighing: take epoxy resin and curing agent by mass ratio 3:1;

[0039] (3) Stirring of materials: Put the weighed epoxy resin and curing agent into the stirrer and stir well. When pouring, try to avoid sticking to the side wall of the container, so that the raw materials cannot be fully stirred evenly. The stirring time is 3 minutes. , to prepare transparent glue;

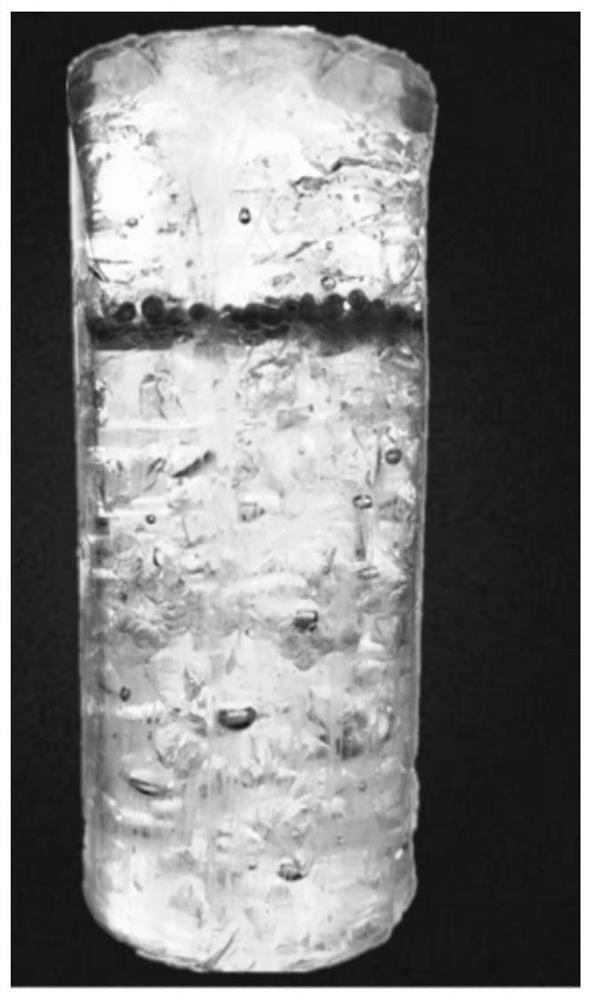

[0040] (4) Vacuuming: Put the transparent glue into the vacuum barrel to remove the air bubbles. During the vacuuming process, the vacuum barrel can be shaken continuously to vibra...

Embodiment 2

[0047] A method for preparing a heterogeneous anisotropic transparent rock-like material sample, comprising the following steps:

[0048] (1) Material cleaning: first clean the transparent colorless glass sand and transparent colored glass sand with plasma water. Impurity removal;

[0049] (2) Material weighing: take epoxy resin and curing agent by mass ratio 3:1;

[0050] (3) Stirring of materials: Put the weighed epoxy resin and curing agent into the stirrer and stir well. When pouring, try to avoid sticking to the side wall of the container, so that the raw materials cannot be fully stirred evenly. The stirring time is 3 minutes. , to prepare transparent glue;

[0051] (4) Vacuuming: Put the transparent glue into the vacuum barrel to remove the air bubbles. During the vacuuming process, the vacuum barrel can be shaken continuously to vibrate the transparent glue, so that the air bubbles in the transparent glue can be discharged more easily. , the vacuuming time is 5-8 mi...

Embodiment 3

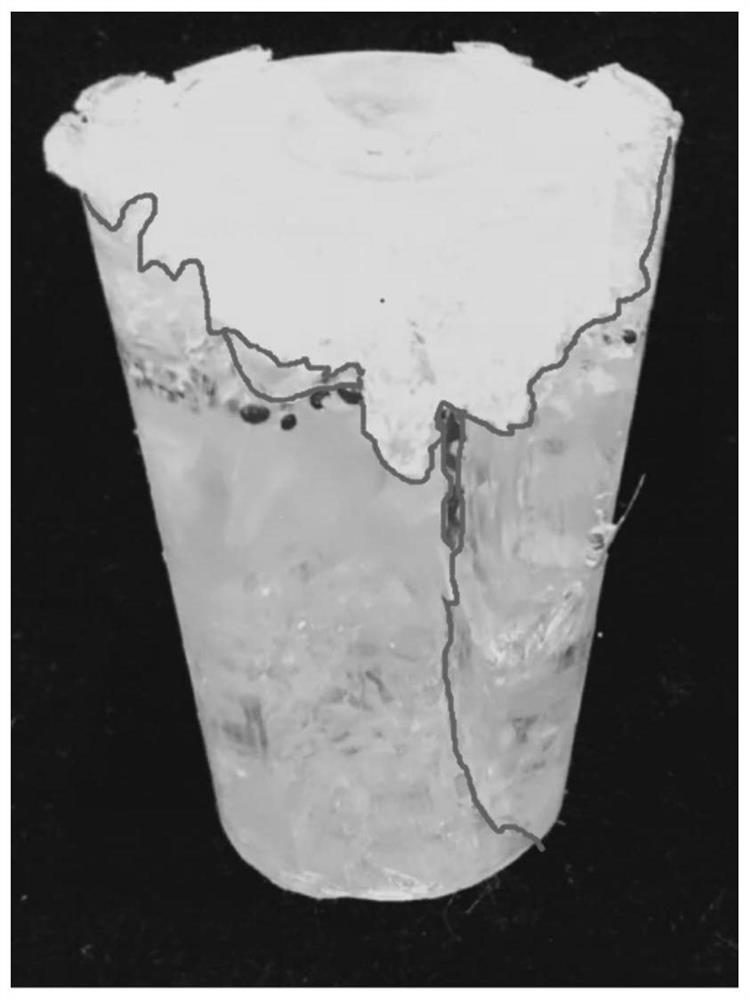

[0058] The preparation method of the heterogeneous anisotropic transparent rock-like material sample comprises the following steps (the schematic diagram of the preparation method is as follows: Figure 5 ):

[0059] (1) Material cleaning: first clean the transparent colorless fused silica sand, transparent colorless glass sand and transparent colored glass sand with plasma water. Dry it down, take it out, and remove the impurities with tweezers;

[0060] (2) Material weighing: take epoxy resin and curing agent by mass ratio 3:1;

[0061] (3) Stirring of materials: Put the weighed epoxy resin and curing agent into the stirrer and stir well. When pouring, try to avoid sticking to the side wall of the container, so that the raw materials cannot be fully stirred evenly. The stirring time is 3 minutes. , to prepare transparent glue;

[0062] (4) Vacuuming: Put the transparent glue into the vacuum barrel to remove the air bubbles. During the vacuuming process, the vacuum barrel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com