Laser annealing device

A laser annealing and laser technology, applied to lasers, laser components, phonon exciters, etc., can solve problems such as laser size or shape changes, irradiation position shaking, annealing process variables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in more detail below through detailed embodiments of the present invention with reference to the accompanying drawings.

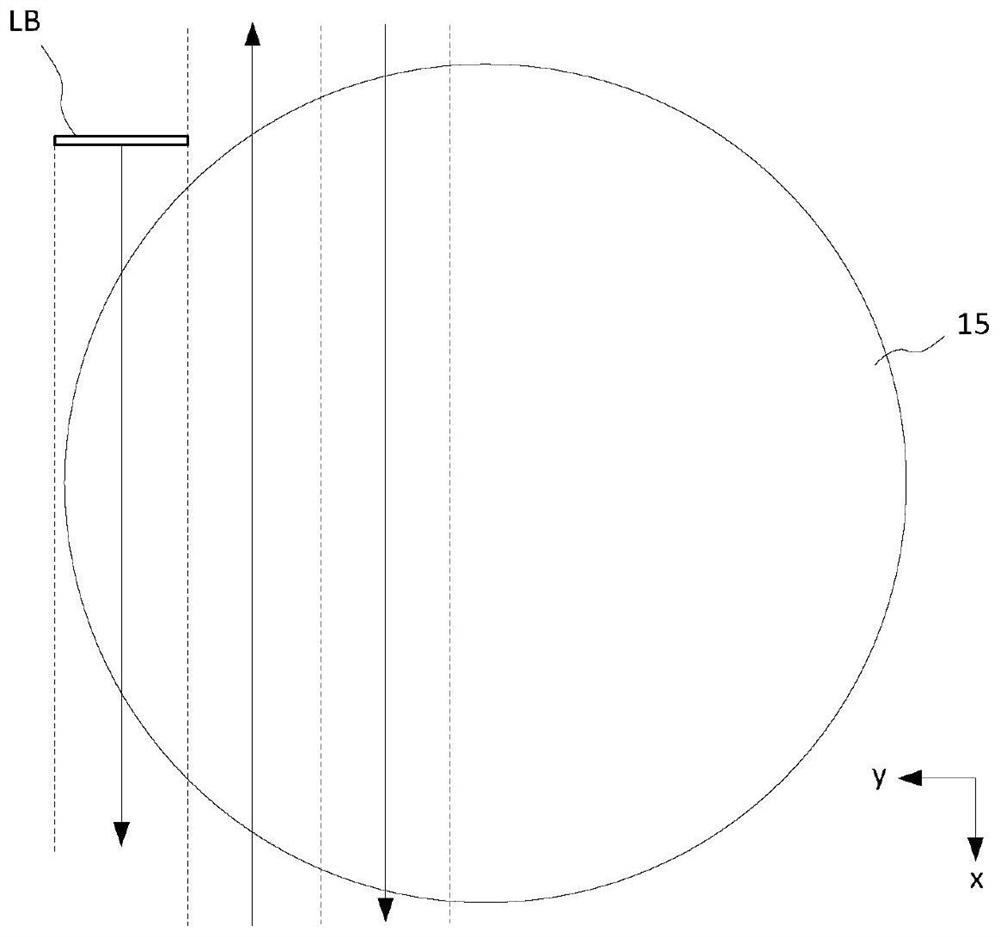

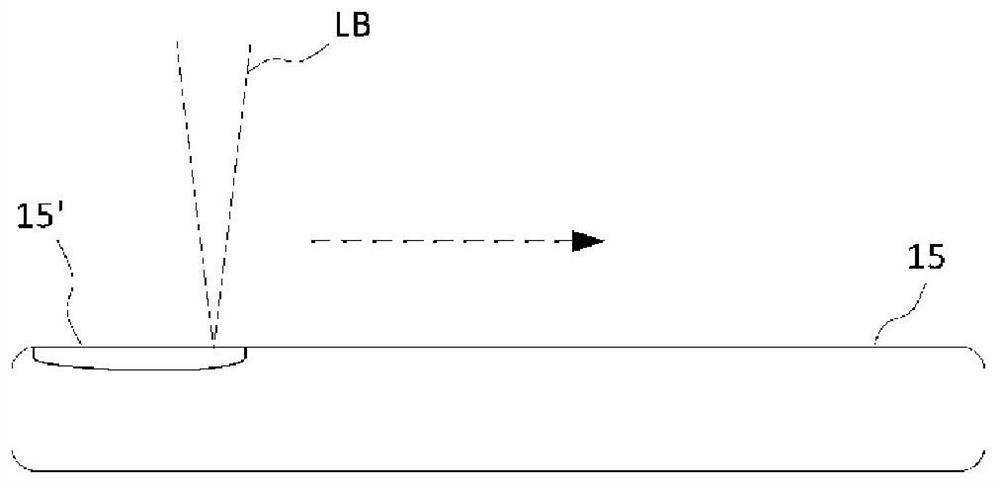

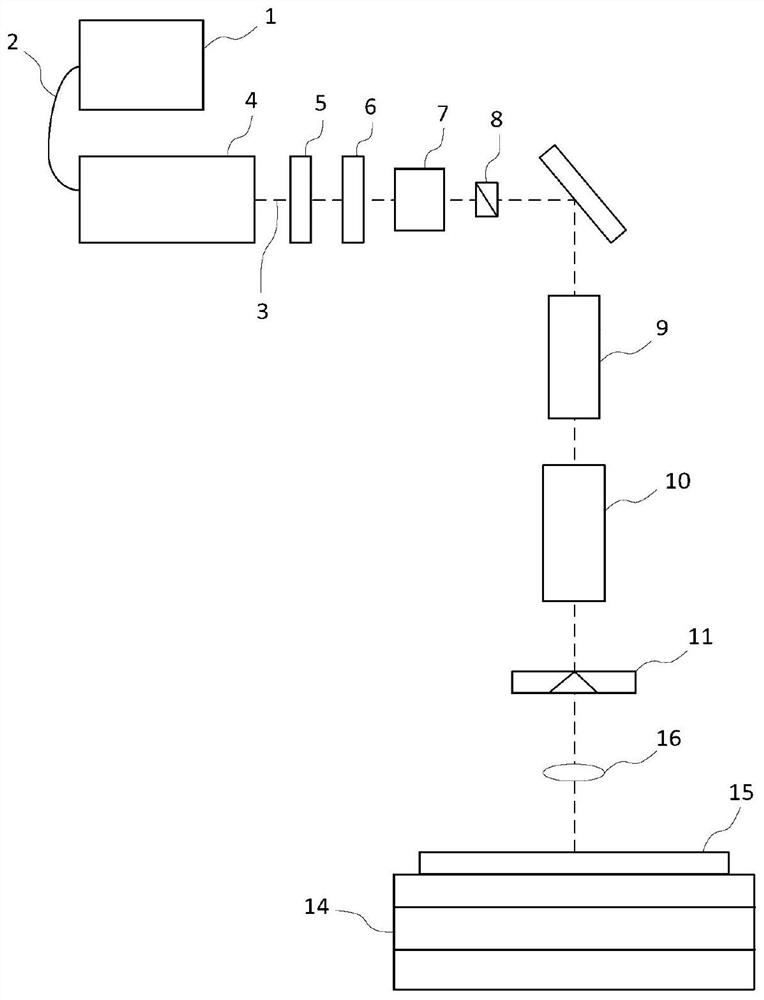

[0043] Figure 4 It is a conceptual diagram showing the configuration of a laser annealing apparatus according to an embodiment of the present invention.

[0044] refer to Figure 4 , the present embodiment is formed by the following structure in the same way as in the past: a laser light source 110, which emits laser light; a laser correction part, which is used to check the laser state and path of the laser light emitted from the laser light source 110 reaching the substrate 115 and correct it according to the inspection result. The state and path of the laser light; the laser shaping unit 140, which receives the laser light radiated from the laser light source 110 and passes through the first correction unit of the laser correction unit, and then shapes the line beam with a predetermined size and form to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com