Method for improving purity of desulfurizing agent for limestone gypsum wet desulphurization

A desulfurization agent and limestone technology, applied in the industrial field, can solve the problems affecting the purity and moisture content of the desulfurization product gypsum, high moisture content, and adverse effects of the operation of the dust collector at the end of the kiln, so as to reduce the phenomenon of sticking to the wall and reduce the moisture content , the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

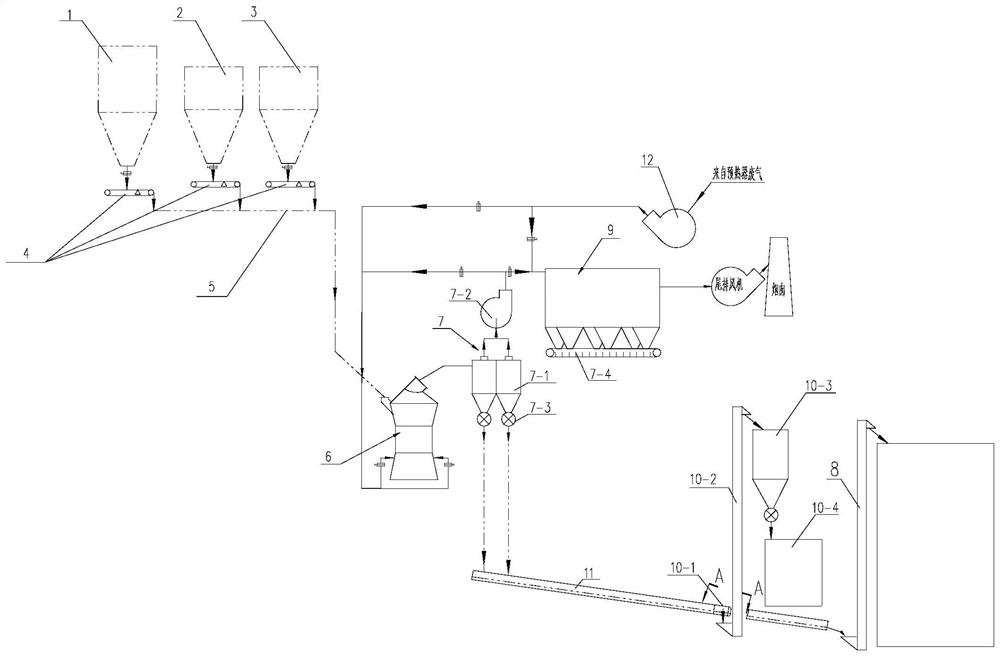

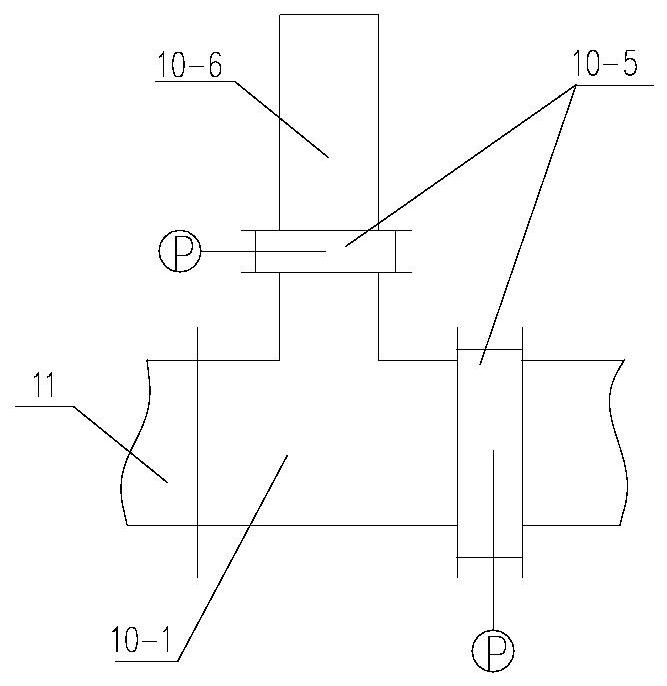

[0017] Example 1, see figure 1 and figure 2 A method for improving the purity of a desulfurizing agent for wet desulfurization of limestone gypsum, using a desulfurizing agent preparation system to improve the purity of the desulfurizing agent, comprising at least one limestone raw meal unit 1, shale raw meal unit 2 and iron ore raw meal unit 3, each Each raw material unit includes a silo and a belt scale 4 located below the silo; a raw material feeding belt 5 is arranged below the corresponding belt scale; the discharge end of the raw material feeding belt extends to the grinding equipment 6 The upper feeding port; the discharge port of the grinding equipment is connected to the finished product collection device 7, and the discharge port of the finished product collection device is adjacent to the inclined finished product trough 11, and the lowest point of the finished product trough extends to the raw material storage. Storehouse hoist 8; the tail gas outlet of the above...

Embodiment 2

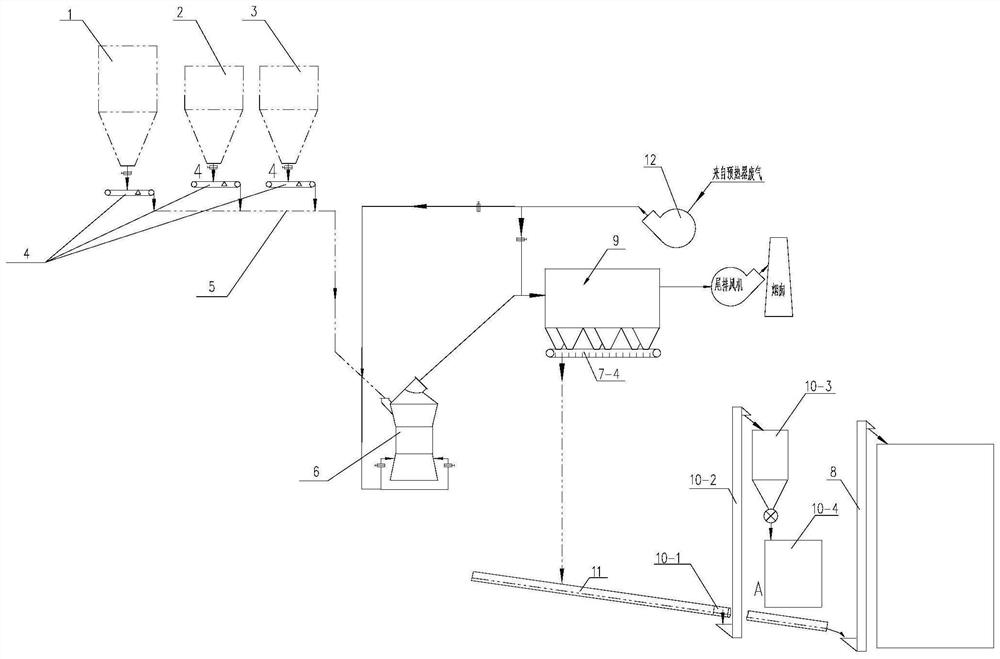

[0025] Example 2, see image 3 , the finished product collection device is the kiln tail dust collector 9, utilizes the kiln tail dust collector 9 to directly collect raw material finished products, and the summary zipper machine 7-4 at the bottom of the kiln tail dust collector 9 is adjacent to the finished product trough, and its feeding operation The sequence and timing are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com