Automatic winding production device for disposable extension tube

A production device and extension tube technology, which is applied to packaging, transportation and packaging, and strapping machine parts, etc., can solve the problems of difficult device connection, low efficiency, uneven glue application, etc., to save layout space and assemble The effect of high success rate and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

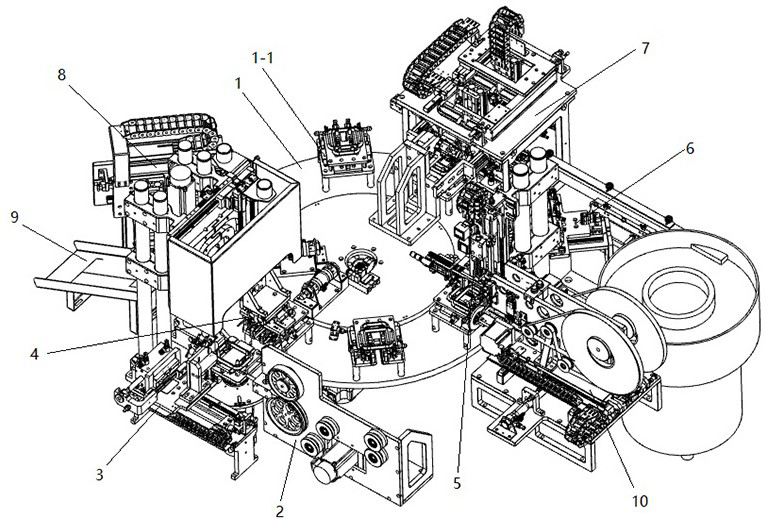

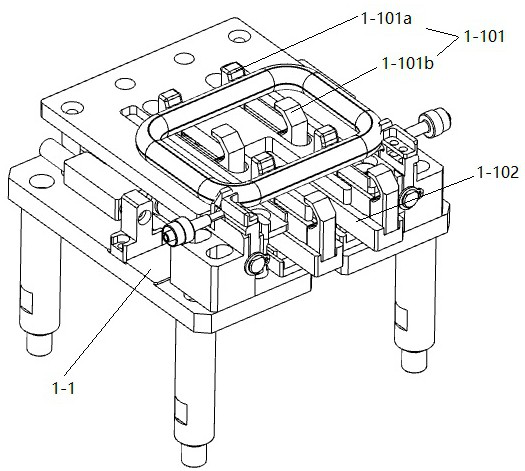

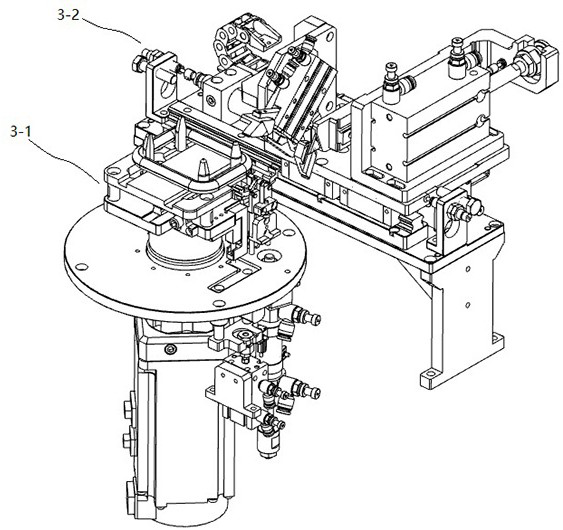

[0043] In order to better understand the present invention, please combine figure 1As shown, the automatic winding production device for disposable extension tubes includes a conveying turntable 1 and a feeding mechanism 2 arranged around the conveying turntable 1, a tube pulling winding mechanism 3, a first grabbing robot 4, a binding mechanism 5, a coating Glue mechanism 6, joint assembly mechanism 7, second grasping manipulator 8 and discharge slideway 9. The transfer turntable 1 is disc-shaped, and a plurality of carrier stages 1-1 are arranged on the transfer turntable 1, and the position of the carrier stage 1-1 is compatible with the first grasping manipulator 4, the binding mechanism 5, the gluing mechanism 6, and the joint assembly mechanism 7. The position of the second grasping manipulator corresponds to position 8. Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com