In-situ preparation method of cementing material for offshore area infrastructure

A cementitious material and basic technology, which is applied in the field of building materials to achieve the effects of high efficiency, lower transportation costs, and lower chloride ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

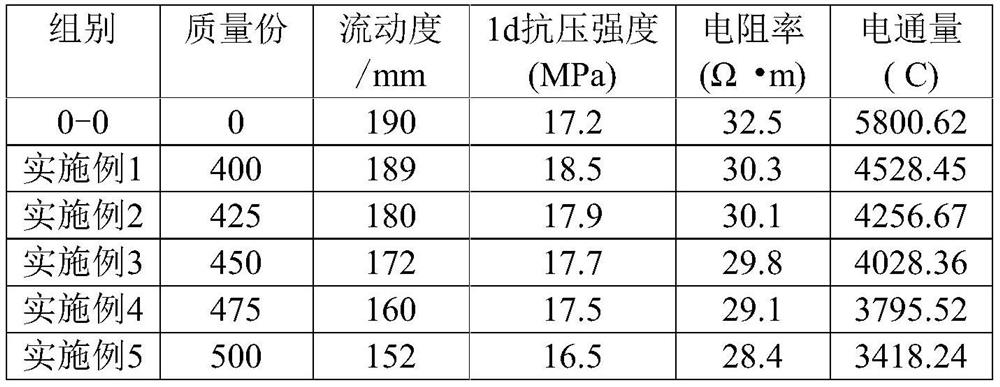

Examples

Embodiment 1

[0032] A cementitious material for infrastructure construction in remote sea areas, which is prepared from coral sand, Portland cement (P·I 52.5), seawater, sea sand, and polycarboxylate high-performance water reducer according to the mass ratio. The preparation method includes the following steps step:

[0033] 1) Select sea sand raw materials that are continuously graded and contain seawater, wash and air-dry the sea sand raw materials to obtain air-dried sea sand raw materials;

[0034] 2) crushing coral bone raw materials of different sizes to obtain coral sand aggregates; then sending the coral sand aggregates into a horizontal ball mill for grinding to obtain coral sand powder;

[0035] 3) Send the coral sand aggregate and air-dried sea sand raw materials into a horizontal ball mill for grinding to obtain nano-micron calcium-silica powder; then mix the nano-micron calcium-silica powder with seawater to obtain nano-micron calcium Silica powder slurry, the dosage is 5%; ...

Embodiment 2

[0039] A cementitious material for infrastructure construction in remote sea areas, which is prepared from coral sand, Portland cement (P·I 52.5), seawater, sea sand, and polycarboxylate high-performance water reducer according to the mass ratio. The preparation method includes the following steps step:

[0040] 1) Select sea sand raw materials that are continuously graded and contain seawater, wash and air-dry the sea sand raw materials to obtain air-dried sea sand raw materials;

[0041] 2) crushing coral bone raw materials of different sizes to obtain coral sand aggregates; then sending the coral sand aggregates into a horizontal ball mill for grinding to obtain coral sand powder;

[0042]3) Send the coral sand aggregate and air-dried sea sand raw materials into a horizontal ball mill for grinding to obtain nano-micron calcium-siliceous powder; then mix the nano-micron-scale calcium-silica powder with seawater to obtain nano-micron calcium Silica powder slurry, the dosage ...

Embodiment 3

[0046] A cementitious material for infrastructure construction in remote sea areas, which is prepared from coral sand, Portland cement (P·I 52.5), seawater, sea sand, and polycarboxylate high-performance water reducer according to the mass ratio. The preparation method includes the following steps step:

[0047] 1) Select sea sand raw materials that are continuously graded and contain seawater, wash and air-dry the sea sand raw materials to obtain air-dried sea sand raw materials;

[0048] 2) crushing coral bone raw materials of different sizes to obtain coral sand aggregates; then sending the coral sand aggregates into a horizontal ball mill for grinding to obtain coral sand powder;

[0049] 3) Send the coral sand aggregate and air-dried sea sand raw materials into a horizontal ball mill for grinding to obtain nano-micron calcium-siliceous powder; then mix the nano-micron-scale calcium-silica powder with seawater to obtain nano-micron calcium Silica powder slurry, the dosage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com