Method for preparing light porous sintered material from aluminum ash

A technology of sintered materials and aluminum ash, which is applied in the field of preparing porous sintered materials by using waste aluminum ash, can solve the problems of low utilization rate and inability to do a large amount of aluminum ash, and achieve low production cost, rich pore structure, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

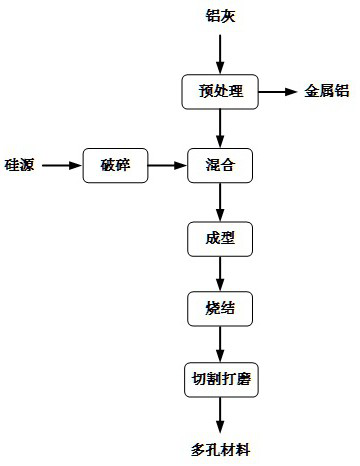

Method used

Image

Examples

Embodiment 1

[0034] In this example, primary aluminum ash (see Table 1 for specific components) is used as raw material. Since the primary aluminum ash has a relatively high content of metallic aluminum and a high recovery value, it is prioritized for recycling and separation.

[0035] Table 1 Chemical composition of primary aluminum ash (dry basis)

[0036]

[0037] Concrete preparation method comprises the following steps:

[0038] (1) Raw material pretreatment: Weigh 3.0kg of primary aluminum ash raw material, and after several times of graded grinding-screening, 2kg of fine aluminum ash with a particle size of less than 150μm is sorted out; the large particle samples separated by grinding are mainly metallic aluminum , can be recycled by smelting;

[0039] (2) Compounding of silicon raw materials: Weigh 1.0kg of quartz sand raw materials and grind them until the particle size range reaches D 90 <75μm; then mix the pulverized silicon raw material with fine aluminum ash evenly;

[...

Embodiment 2

[0047] The present embodiment adopts primary aluminum ash as a raw material, and the specific preparation method comprises the following steps:

[0048] (1) Raw material pretreatment: Weigh 3.0kg of primary aluminum ash raw material, and after several times of graded grinding-screening, 2kg of fine aluminum ash with a particle size of less than 150μm is sorted out; the large particle samples separated by grinding are mainly metallic aluminum , can be recycled by smelting;

[0049] (2) Compounding of silicon raw materials: Weigh 2.0kg of micro-silica powder as a raw material. Since the particle size of micro-silica powder itself is very small, this step does not need to be ground, and it is directly mixed with fine aluminum ash;

[0050] (3) Dry pressing molding: put the compounded mixture in a pressure mold for dry pressing molding, the molding pressure is 6.0Mpa, and demold after holding the pressure for 1min to obtain a dry billet;

[0051] (4) High-temperature sintering: p...

Embodiment 3

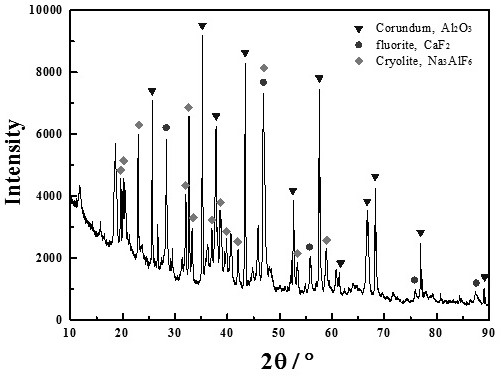

[0054] In this example, the secondary aluminum ash (see Table 2 for specific components) is directly used as the raw material. Due to the small particle size of the secondary aluminum ash, the low content of aluminum in it, and the low recovery value, the preparation process no longer considers the composition of the aluminum metal. to recycle.

[0055] Table 2 Chemical composition of secondary aluminum ash (dry basis)

[0056]

[0057] Concrete preparation method comprises the following steps:

[0058] (1) Raw material pretreatment: Weigh 2.0kg of secondary aluminum ash raw material and grind it to make the particle size range reach D 90 <75μm;

[0059] (2) Compounding of silicon raw materials: Weigh 0.5kg of quartz sand raw materials and grind until the particle size range reaches D 90 <75μm; then mix the pulverized silicon raw material with fine aluminum ash evenly;

[0060] (3) Dry pressing molding: put the compounded mixture in a pressure mold for dry pressing mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com