Non-yellowing polyurethane sponge and preparation method thereof

A technology of polyurethane sponge and isocyanate, applied in the field of polyurethane foam, can solve the problem of yellowing of the sponge, and achieve the effect of avoiding yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a method for preparing the above-mentioned non-yellowing polyurethane sponge, comprising: mixing the first polyether polyol, the second polyether polyol, water, an amine catalyst, a foam stabilizer and a physical foaming agent Stir for the first time, then add isocyanate for the second time, heat and dry to obtain non-yellowing polyurethane sponge.

[0054] The present invention does not have special limitation to the source of all raw materials, can be commercially available; The first polyether polyol, the second polyether polyol, water, amine catalyst, foam stabilizer, physical foaming agent and The isocyanates are all the same as described above and will not be repeated here.

[0055] Mix the first polyether polyol, the second polyether polyol, water, amine catalyst, foam stabilizer and physical blowing agent for the first stirring to obtain component A; the first stirring speed Preferably it is 1000-1500r / min; the time for the f...

Embodiment 1

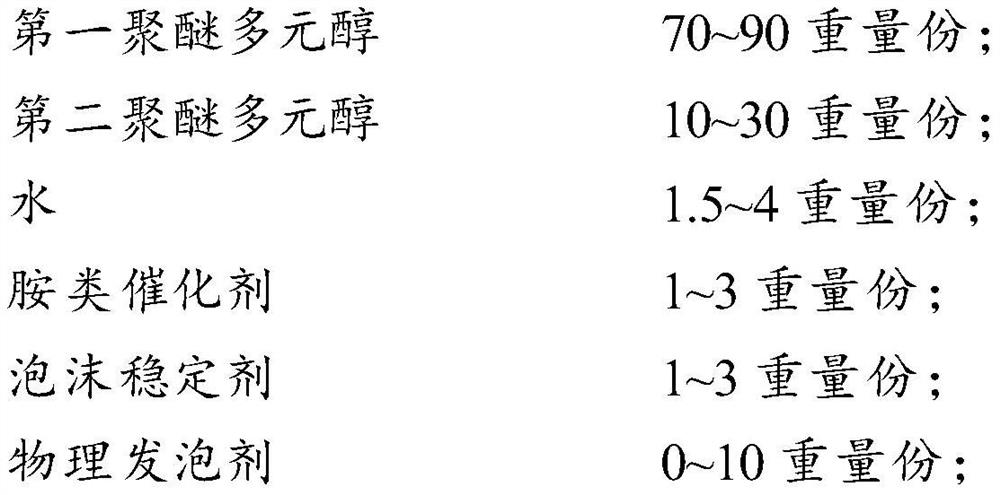

[0068] The formula of polyurethane sponge is:

[0069]

[0070] Mix the first polyether polyol, the second polyether polyol, water, an amine catalyst and a foam stabilizer and stir at 1000r / min for 45s, then add isocyanate and stir at a high speed of 2500r / min for 7s to obtain a polyurethane blend.

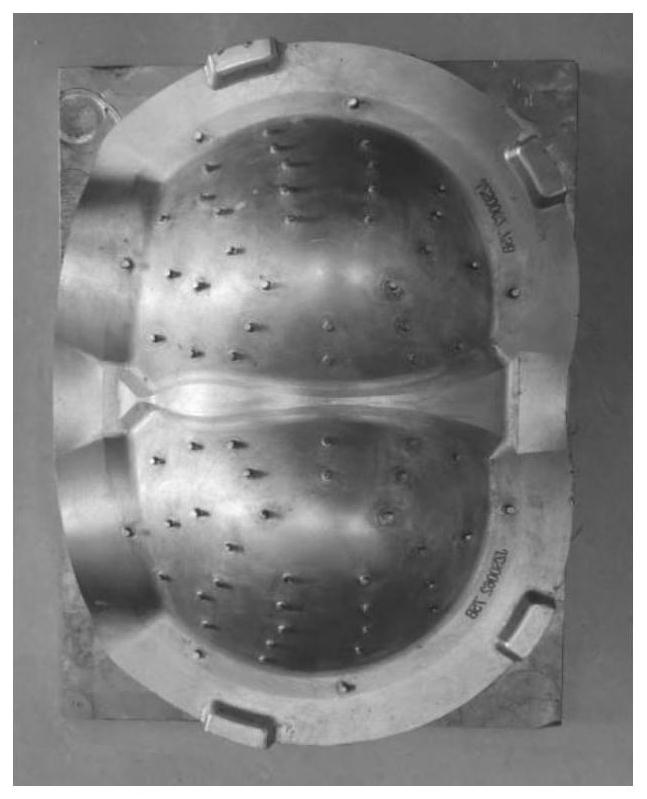

[0071] Sponge bra molds (see figure 1 and figure 2 , which is a picture of a sponge bra mold) heated to 60°C, coated with oil-based release agent LK 706 provided by Evonik, then put the sponge bra mold into a heating and drying oven, and kept the temperature at 60°C, and the polyurethane prepared from the above formula The blend is poured into a sponge bra mold, the mold is covered, placed in a heating and drying oven, kept warm for 8 minutes, and demolded to obtain a bra cup with fine cells and a smooth surface.

Embodiment 2

[0073] The formula of polyurethane sponge is:

[0074]

[0075] According to the production process of Example 1, a bra cup body with fine cells and smooth surface is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com