Lithium ion battery electrolyte and lithium ion battery thereof

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as expensive additives, and achieve the effects of easy cost, cost control, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the present invention clear and understandable, the present invention will be further described below through specific embodiments and comparative examples:

[0016] 1. Preparation of electrolyte:

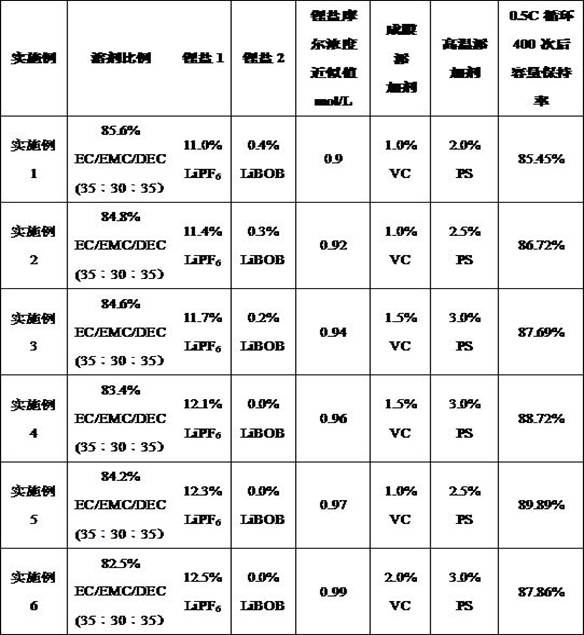

[0017] In a glove box filled with argon (moisture content 6 , lithium dioxalate borate LiBOB, vinylene carbonate VC, and 1,3-propane sultone PS are mixed according to 85.6%: 11.0%: 0.4%: 1.0%: 2.0%, so that the total amount of organic solvent, lithium salt, The sum of the proportions of vinyl ester and 1,3-propane sultone components is 100%, and the molar concentration of lithium salt is 0.9 mol / L to obtain the lithium ion battery electrolyte in Example 1.

[0018] The electrolyte preparation method of Examples 2-6 is the same as that of Example 1, the difference is that the specific proportions of the components in the electrolyte are different.

[0019] 2. Preparation of positive electrode sheet:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com