Sample adding needle for preparing micro-droplets and preparation method of micro-droplets

A technology for adding sample needles and microdroplets, which is applied in chemical instruments and methods, fluid controllers, measuring tubes/pipettes, etc. Uniform, volume-controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

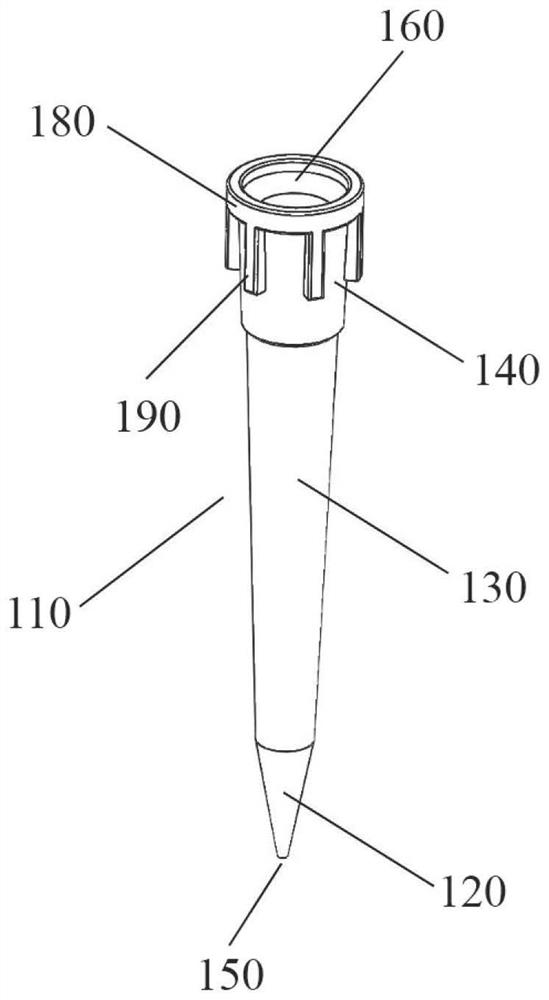

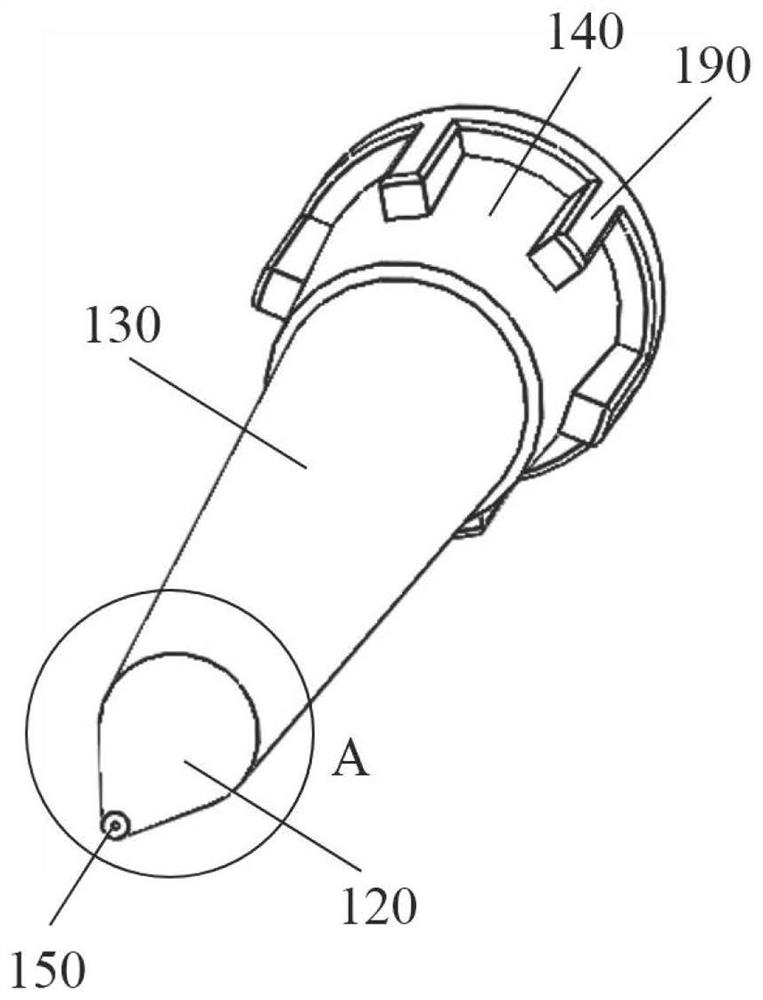

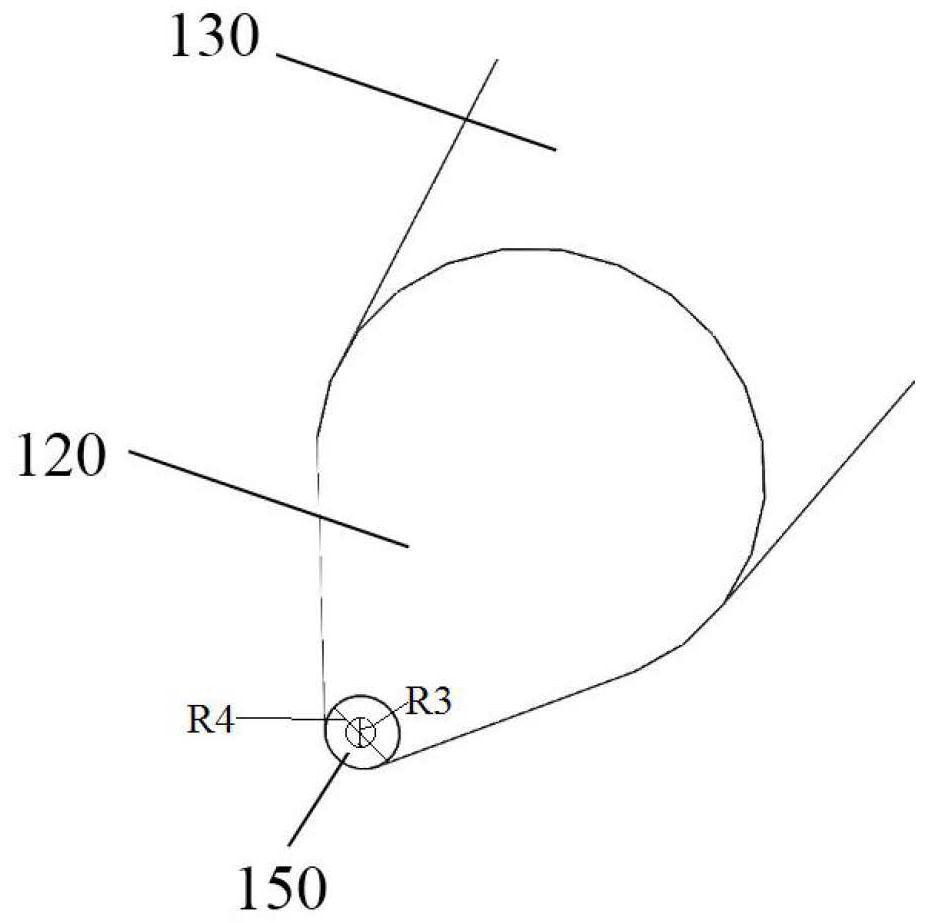

[0103] The liquid storage volume of the sample needle 110 described in the present application is 60 microliters, and the material for preparing the sample needle 110 is polypropylene (PP, the contact angle of pure aqueous solution is 88 degrees), the height of the spit part 120 is 5 mm, and the taper is 20 degrees. °, the wall thickness is 0.15mm, the height of the liquid storage part 130 is 18.7mm, the taper is 4°, the wall thickness is 0.5mm, the height of the adapter part is 6mm, the taper is 4°, the inner diameter of the spit opening 150 is 100μm, and the outer The diameter is 400 μm. According to the above dimensions, the precision metal injection mold cavity and inner core are made, and the injection molding process is used for large-scale automatic sample needle processing. The processing yield is 99.98% (batch testing quantity 10,000 pieces).

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com