Salt pan for recovering sylvite at low cost and method for recovering sylvite by adopting salt pan

A low-cost, salt field technology, applied in the direction of alkali metal chloride, etc., can solve the problems of complex process, large energy consumption, short duration of low temperature, etc., and achieve the effect of simple process and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0084] Example: A potash mine project abroad is located in the largest potash production area in the world. The climate in this area is characterized by large temperature differences, usually up to 65°C within a year. The temperature difference and rainfall also vary greatly from season to season. The potassium salt in the project area is integrated in the sedimentary rocks of the Middle Devonian, with a total thickness of about 30-40m and a buried depth of about 1650-1750m. Evaporites are generally formed by the evaporation of seawater flowing into inland basins and the precipitation of dissolved salts.

[0085] 1. Project scale

[0086] The project design KCl production scale is 2 million t / a.

[0087] 2. Mine Work System

[0088] 325d / a, 3 classes / d, 8h / classes.

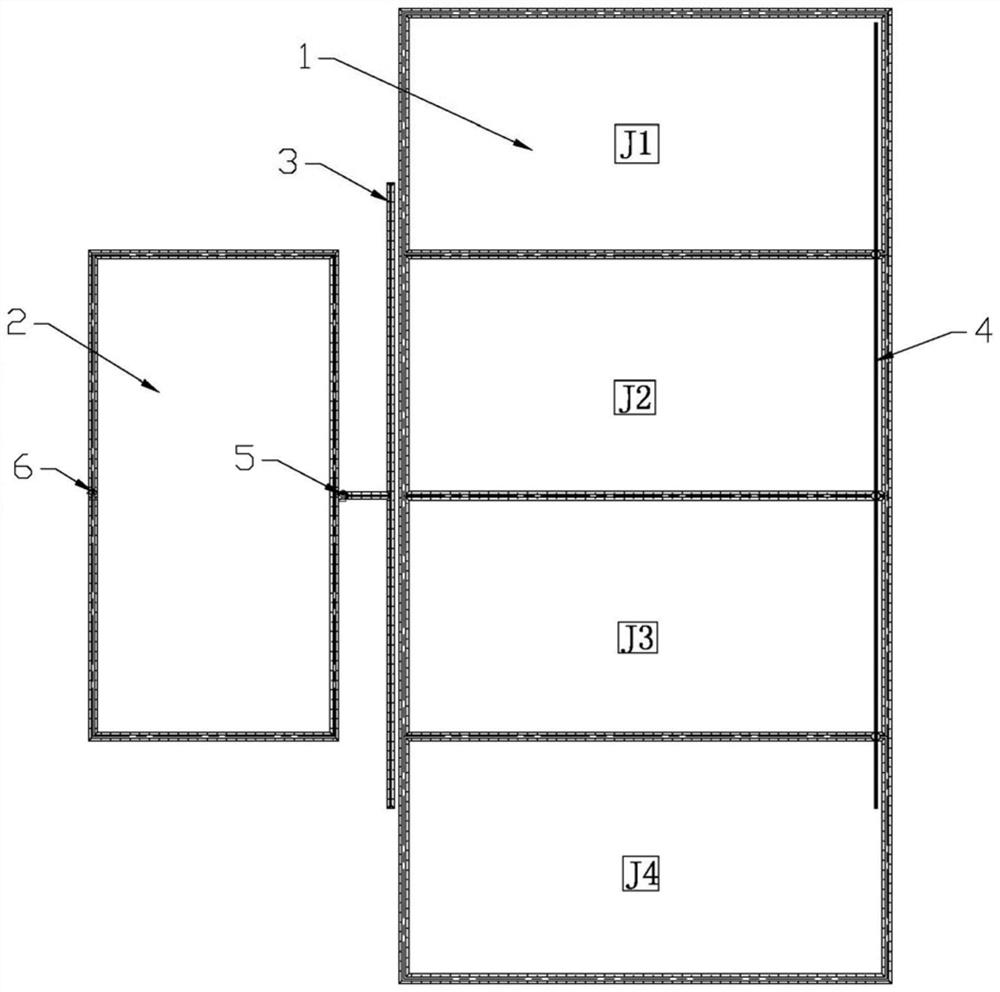

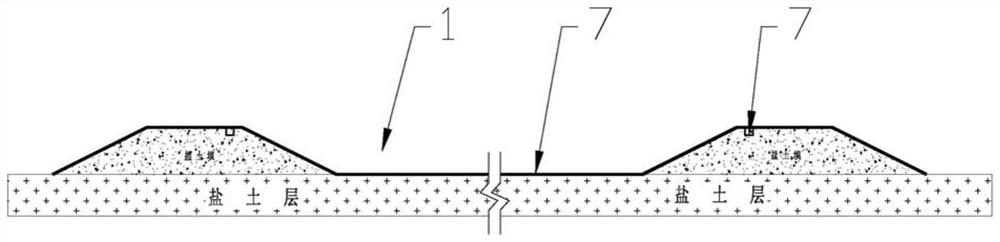

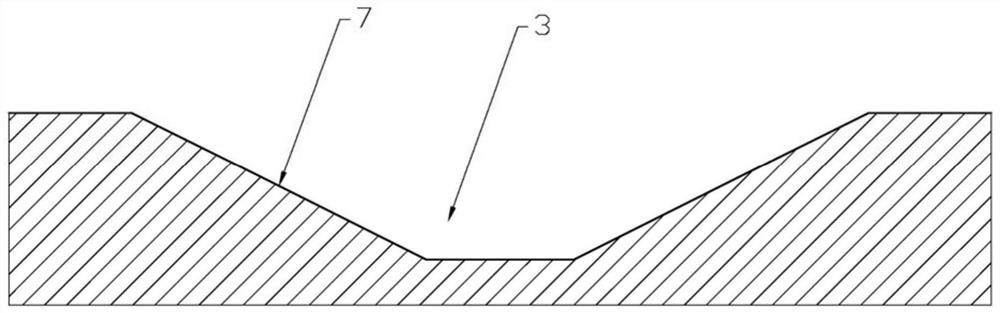

[0089] 3. Yantian project

[0090] (1) Process flow of Yantian

[0091] According to the solubility difference of the three chloride components at different temperatures, the brine is cooled under natural c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com