Detection equipment for vehicle assembly and vehicle assembly production system

A combination technology of testing equipment and vehicles, which is applied to other manufacturing equipment/tools, measuring devices, instruments, etc., can solve problems such as quality problems that cannot be detected in the first time, labor injuries of quality inspectors, and increased production line speed. To move the body repeatedly, avoid accidental injury, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

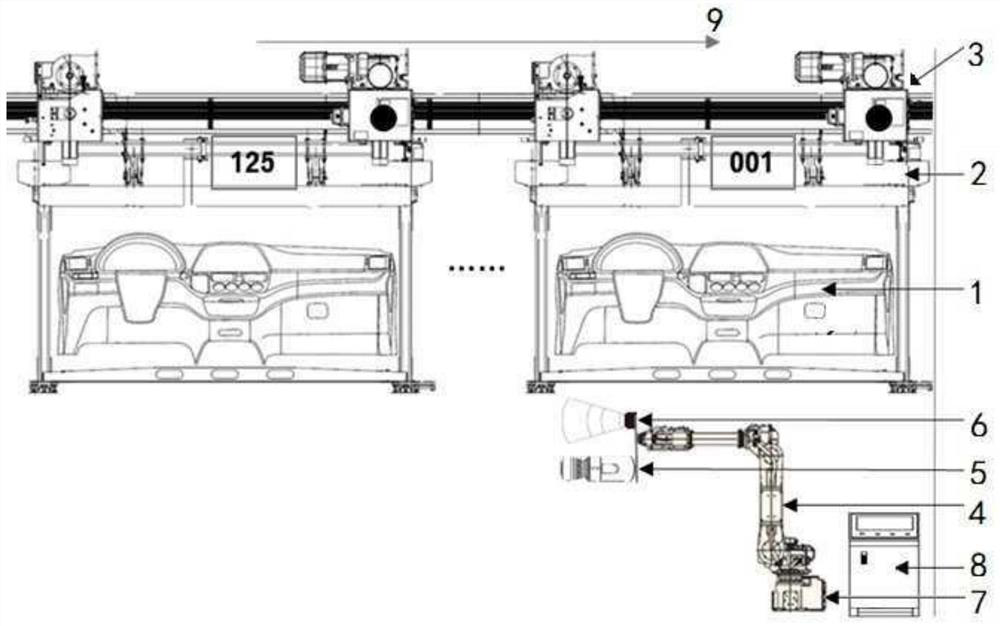

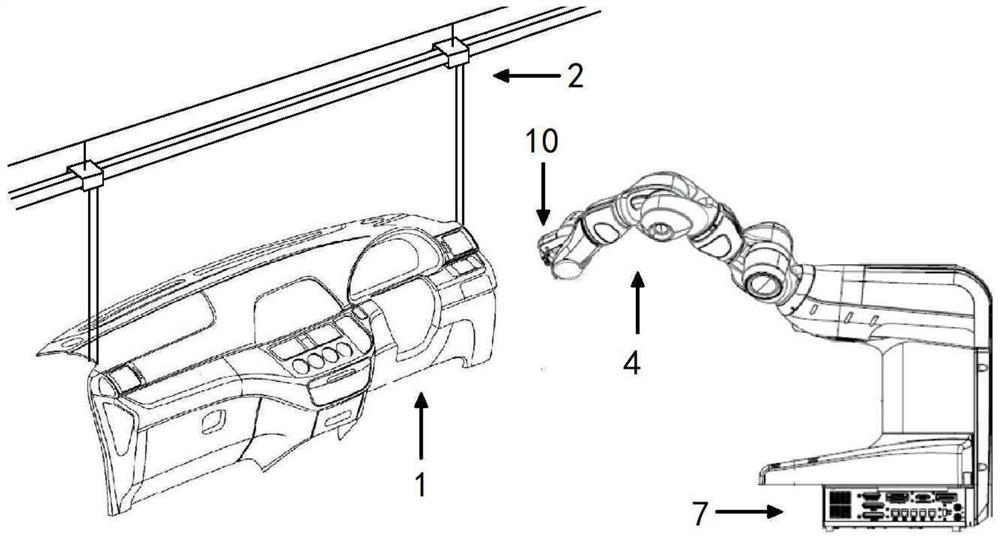

[0037] figure 1 A schematic diagram showing a testing device for a vehicle assembly according to the invention and a vehicle assembly to be tested. The detection of the vehicle assembly is explained in the figures using the instrument panel assembly 1 for the vehicle as an example. The instrument panel assembly 1 is carried by a transport unit 2 designed as a spreader. The individual instrument panel assemblies 1 are passed successively by means of the transport unit 2 in the transport direction 9 on the steel girder through the testing device according to the invention. The transport unit 2 has a motor 3 for driving its movement.

[0038] Detection equipment according to the present invention comprises:

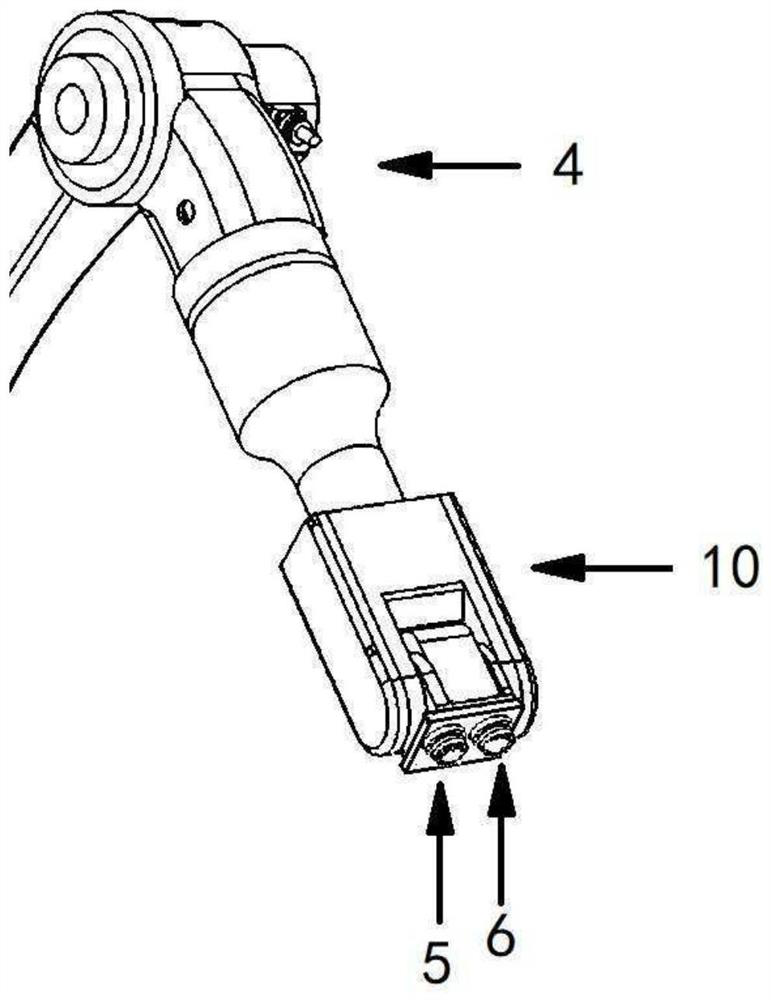

[0039] - a collaborative robot 4 for moving around the dashboard assembly 1 conveyed by the conveying unit 2;

[0040] - a camera 5 installed at the end of the collaborative robot 4 for collecting images of the instrument panel assembly 1;

[0041] - a three-dimensional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com