High-nickel positive electrode-lithium carbon negative electrode lithium ion battery and preparation method thereof

A lithium-ion battery and negative electrode technology, applied in the direction of secondary batteries, battery electrodes, battery pack components, etc., can solve problems such as the energy density of lithium-ion batteries, improve the first discharge efficiency, increase the discharge voltage platform, reduce The effect of polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

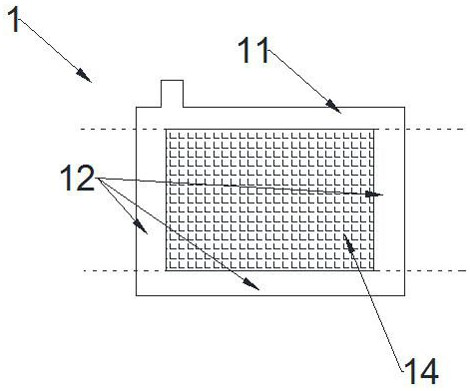

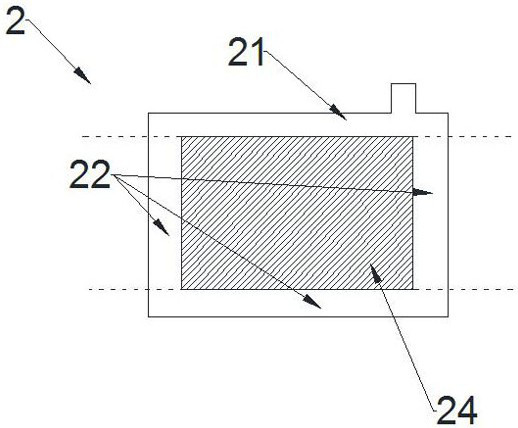

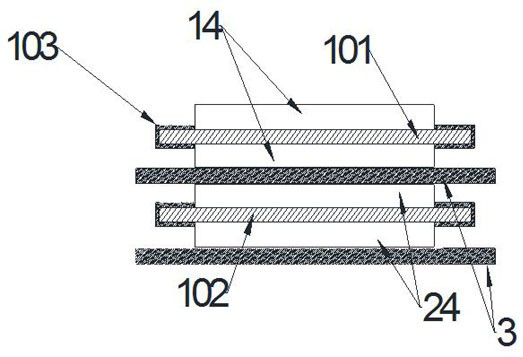

[0040] Such as Figure 1 to Figure 4 As shown, a lithium ion battery with a high nickel positive electrode and a lithium carbon negative electrode, the lithium ion battery includes a positive electrode sheet 1, a negative electrode sheet 2, a ceramic diaphragm 3, an electrolyte and a battery case 4, a positive electrode sheet 1, a ceramic diaphragm 3, and a negative electrode sheet 2. The ceramic separator 3 is stacked repeatedly in sequence to form a dry cell. The lithium-ion battery is made by putting the dry cell into the battery case 4 and injecting electrolyte, forming an opening, sealing, and dividing the capacity. The positive electrode sheet 1 and the negative electrode sheet 2 They are multi-element high-nickel positive electrode sheet and lithium-carbon composite negative electrode sheet respectively. The positive electrode sheet 1 is provided with reserved tabs 11 for the positive electrode sheet on both sides, and the negative electrode sheet 2 is provided with rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com