Hoisting clamp for Sendzimir mill roll heat treatment

A fixture and roll technology, which is applied in the field of hoisting fixtures for heat treatment of Sendzimir rolls, can solve the problems of reduced service life, safety risks, and product shedding of Q235 welded parts, so as to improve service life, improve high-temperature mechanical properties, grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

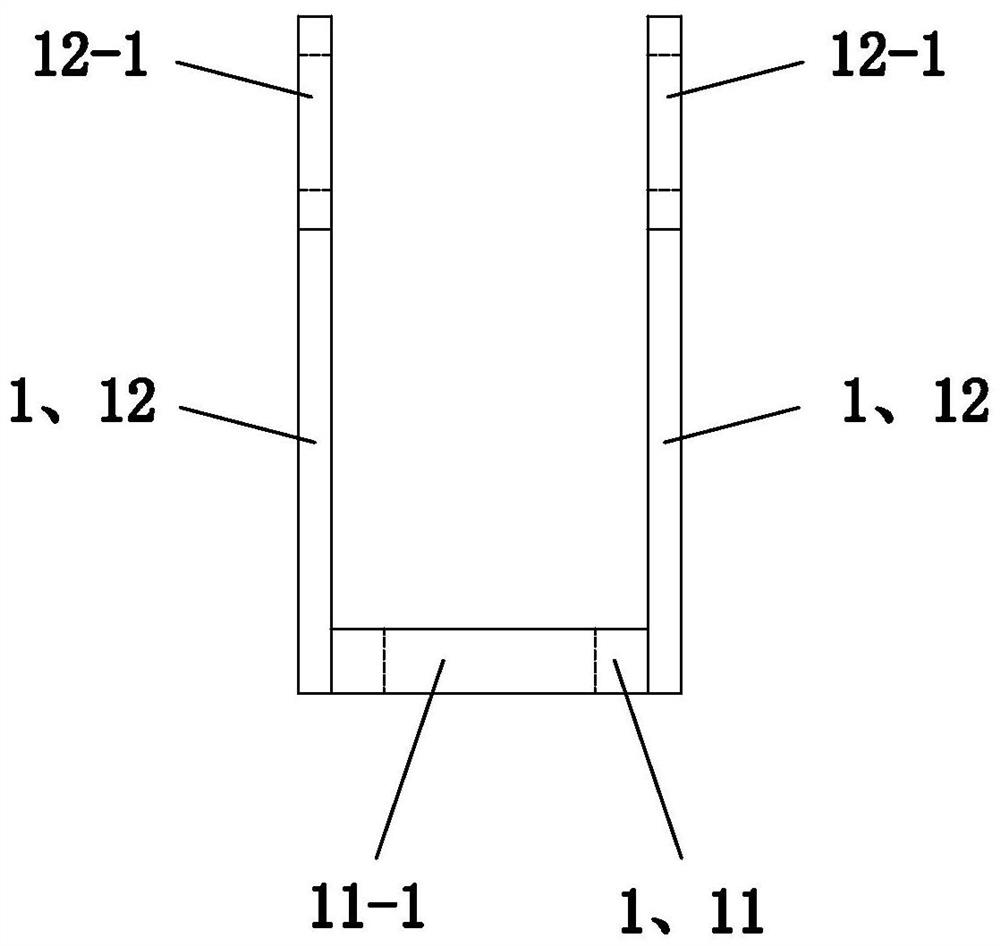

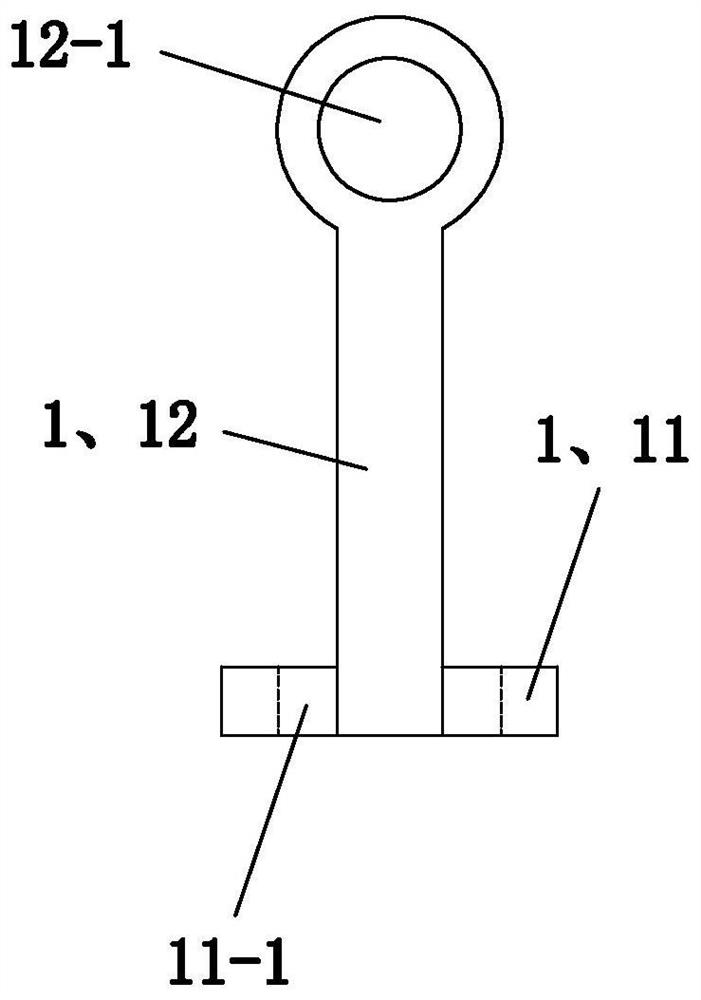

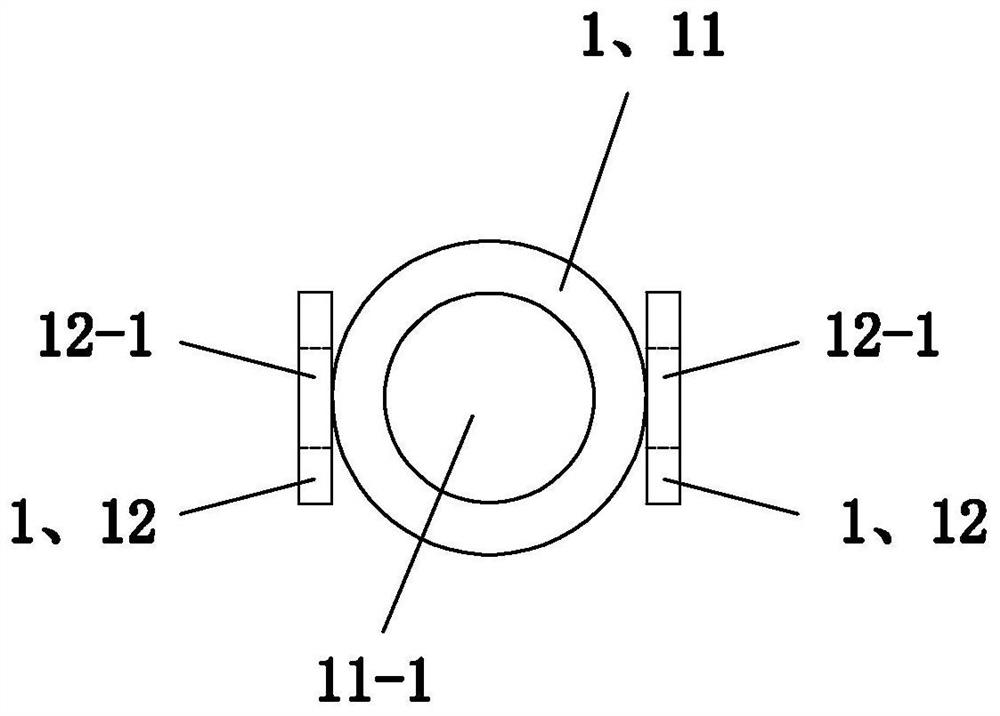

[0029] see Figure 1 to Figure 5 , The lifting jig for heat treatment of Sendzimir rolls in this embodiment includes a jig body 1 and an inverted convex washer 2 .

[0030] The fixture body 1 is an integral pouring piece, including a circular base 11 and lifting parts 12 on both sides; the circular base 11 is provided with a first through hole 11-1; each lifting part 12 is provided with a second Through hole 12-1.

[0031] The inverted convex washer 2 is an integral casting, including a wide outer diameter upper part 21 and a narrow outer diameter lower part 22; the inverted convex washer 2 is provided with a third through hole 2-1.

[0032] The materials of fixture body 1 and inverted convex washer 2 are: 0.5% carbon, 1.2% silicon, 1.2% manganese, 25% chromium, 30% nickel, 0.8 niobium, and the rest are iron and unavoidable impurities.

[0033] The outer diameter of the wide outer diameter upper part 21 of the inverted convex gasket 2 is less than the outer diameter of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com