A microchannel hybrid catalytic hydrogenation device and method for preparing isophorol

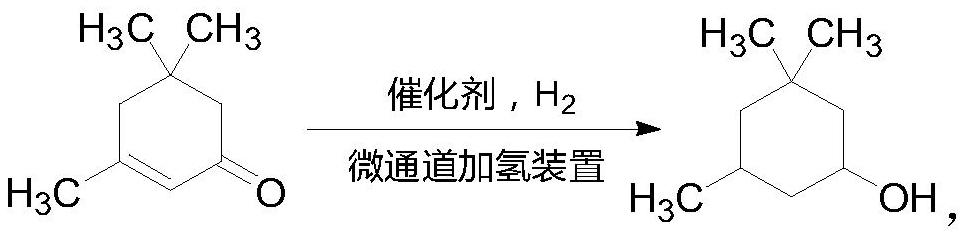

A technology for catalytic hydrogenation of isophorol, applied in chemical instruments and methods, hydrogenation preparation, preparation of hydroxyl compounds, etc., can solve the problem that is not suitable for fine chemical industry and medical industry, gas phase, liquid phase and catalyst contact area Small size, large reaction volume and high yield, etc., to achieve the effect of benefiting consistency and safety, reducing dosage and equipment volume, and reducing the occurrence of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

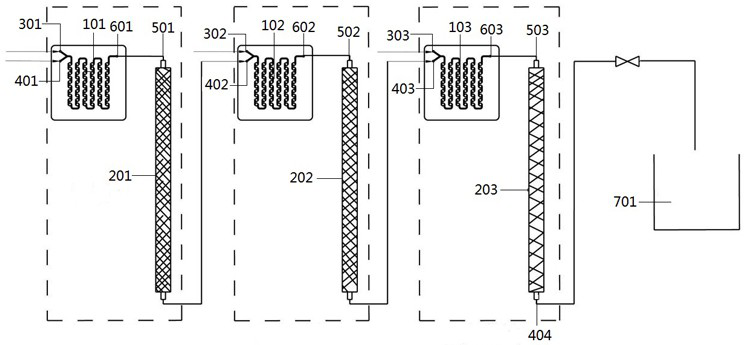

[0035] see figure 1 , the present embodiment takes 3 sets of microchannel mixers and hydrogenation reaction columns connected in sequence as an example to explain the present invention in detail.

[0036] A microchannel hybrid catalytic hydrogenation device for preparing isophorol, with 3 sets of microchannel mixers and hydrogenation reaction columns connected in sequence, the first set of microchannel mixer 101 and hydrogenation reaction column 201, microchannel The two raw material inlets of the mixer 101 are respectively the hydrogen feed port 301 and the isophorone feed port 401, and the raw material inlet 501 of the hydrogenation reaction column 201 is connected with the material outlet 601 of the first set of microchannel mixers; the second set The microchannel mixer 102 and the hydrogenation reaction column 202, the two raw material inlets of the microchannel mixer 102 are respectively the hydrogen feed port 302 and the outlet material feed port 402 of the first set of ...

Embodiment 2

[0051] In this embodiment, four sets of sequentially connected microchannel mixers and hydrogenation reaction columns are taken as an example to explain the present invention in detail.

[0052] A microchannel hybrid catalytic hydrogenation device for preparing isophorol, with 4 sets of microchannel mixers and hydrogenation reaction columns connected in sequence, the first set of microchannel mixers and hydrogenation reaction columns, microchannel mixer The two raw material inlets are the hydrogen feeding port and the isophorone feeding port respectively, and the raw material inlet of the hydrogenation reaction column is connected with the material outlet of the first set of microchannel mixer; the second set of microchannel mixer is connected with the hydrogenation reaction column The two raw material inlets of the column and the microchannel mixer are respectively the hydrogen feeding port and the outlet material feeding port of the first set of hydrogenation reaction column,...

Embodiment 3

[0063] In this embodiment, 6 sets of sequentially connected microchannel mixers and hydrogenation reaction columns are taken as an example to explain the present invention in detail.

[0064] A microchannel hybrid catalytic hydrogenation device for preparing isophorol, with 6 sets of microchannel mixers and hydrogenation reaction columns connected in sequence, the first set of microchannel mixers and hydrogenation reaction columns, microchannel mixer The two raw material inlets are the hydrogen feeding port and the isophorone feeding port respectively, and the raw material inlet of the hydrogenation reaction column is connected with the material outlet of the first set of microchannel mixer; the second set of microchannel mixer is connected with the hydrogenation reaction column The two raw material inlets of the column and the microchannel mixer are respectively the hydrogen feeding port and the outlet material feeding port of the first set of hydrogenation reaction column, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com