Red mud-based ferrate mixture soil remediation agent as well as preparation method and application thereof

A soil remediation agent and ferrate technology, which is applied in the field of soil remediation agent preparation, can solve the problems of rising construction cost, alumina production cost, land occupation, waste of resources, etc., and achieve the advantages of saving iron resources, increasing efficiency, and reducing toxic effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

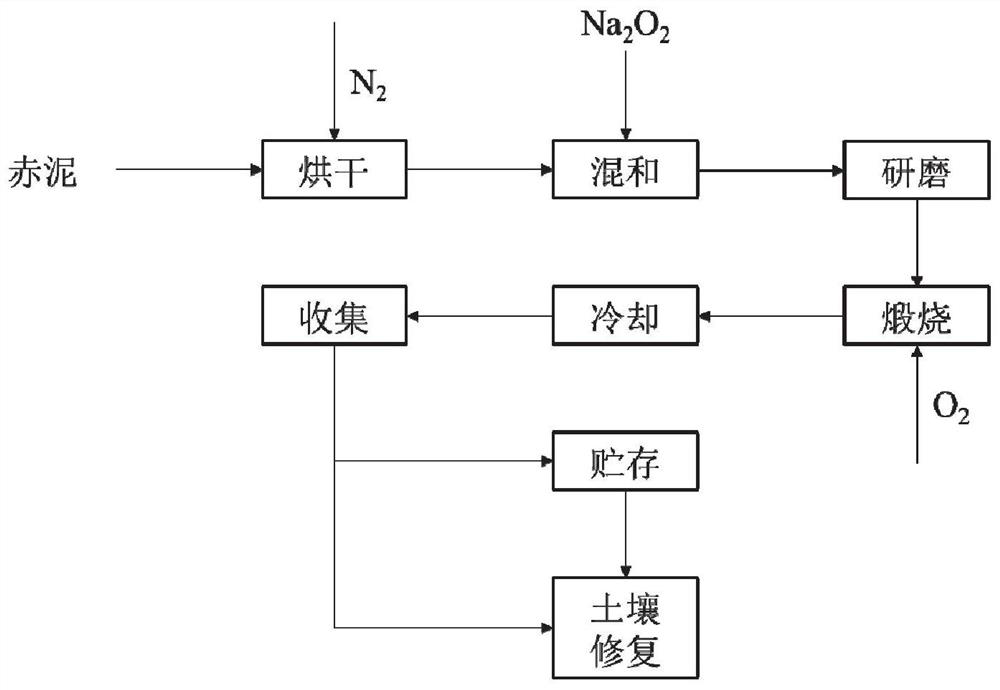

[0026] In a first aspect, the present invention provides a method for preparing a red mud-based ferrate mixture soil remediation agent, comprising the steps of:

[0027] Mix and grind the dried red mud and alkali metal peroxide in proportion;

[0028] The mixed solid powder is calcined to prepare the red mud-based ferrate mixture soil repair agent.

[0029] In the aluminum industry, the red mud, the waste discharged after extracting alumina from bauxite, contains about 10% of valuable iron elements, and most of its occurrence forms are Fe 2 o 3 , a small amount of FeO is present. Fe contained in red mud 2 o 3 As a raw material, it is mixed with an alkali metal peroxide and calcined to obtain a red mud-based ferrate mixture soil remediation agent through a thermochemical oxidation method.

[0030] The reaction mechanism is: red mud (Fe 2 o 3 )+Na 2 o 2 →Na 2 FeO 4 +Na 2 O.

[0031] In some embodiments, the moisture content of the dried red mud is less than 0.1%.

...

Embodiment 1

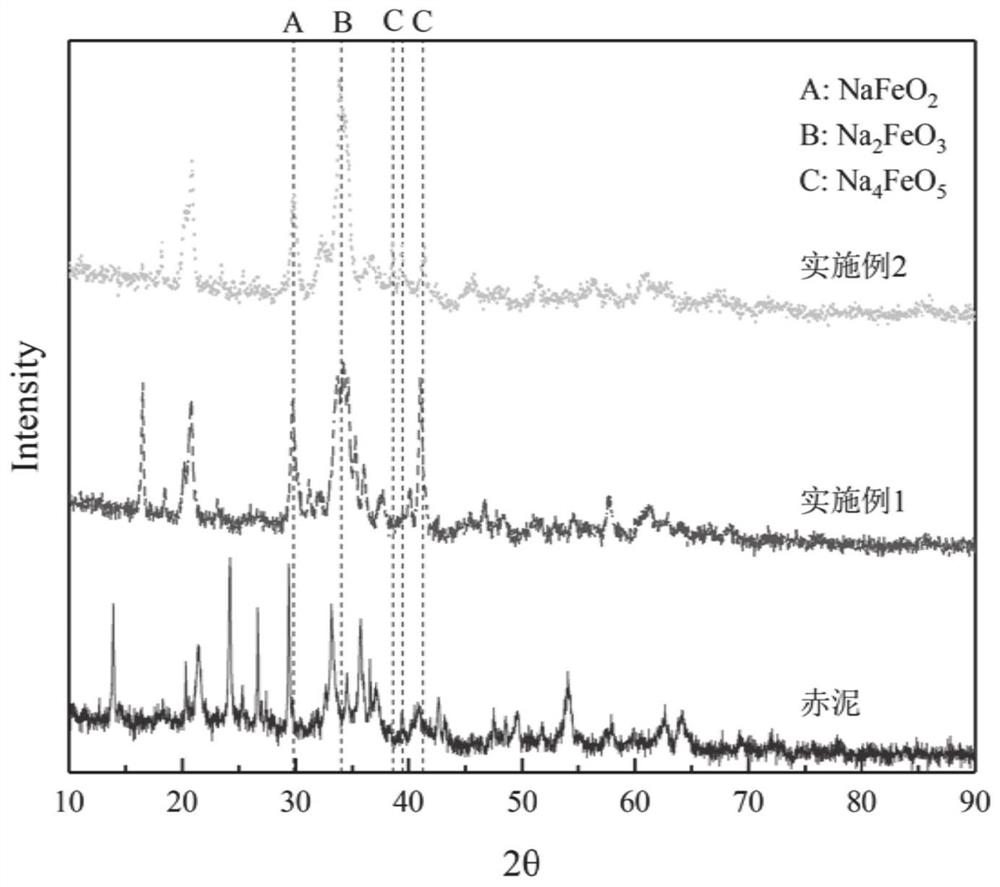

[0049] Take by weighing 8.992g of the waste red mud of the aluminum making industry, put it into a tube furnace and close it, and feed it into a flow rate of 100ml / min. 2 Dry at 180°C for 1 hour, quickly weigh 8.679g after cooling, and quickly weigh 8.690g according to the mass ratio of 1:1 (considering the loss caused by the transfer process) Na 2 o 2 Mix it with the dried red mud, stir and grind it fully so that there are no obvious lumps in the mixture, quickly put it into the tube furnace and close it, and pass in O at a flow rate of 200ml / min. 2 The temperature was raised to 700° C. at a rate of 6° C. / min and then calcined for 1 hour. After the reaction was completed, the product was taken out after the tube furnace was cooled to room temperature, sealed and stored, and a small amount of product was taken to analyze its phase composition by XRD. The results were as follows: figure 2 As shown, the curves from bottom to top are the XRD patterns of the red mud, the produc...

Embodiment 2

[0051] Compared with Example 1, the heating rate of calcination was 5° C. / min, and the others were the same as Example 1. Ferrate (Na 2 FeO 3 and Na 4 FeO 5 ) content is about 7.7%, of which Na 4 FeO 5 The content is about 3.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com