Substrate clamp for vertical double-sided film coating

A double-sided coating and substrate technology, which is applied in sputtering, ion implantation, gaseous chemical plating, etc., can solve the problems of slag loss, chip breaking, and need to turn the film on the coating structure, so as to achieve mass production. The effect of automatic operation and easy mass production of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

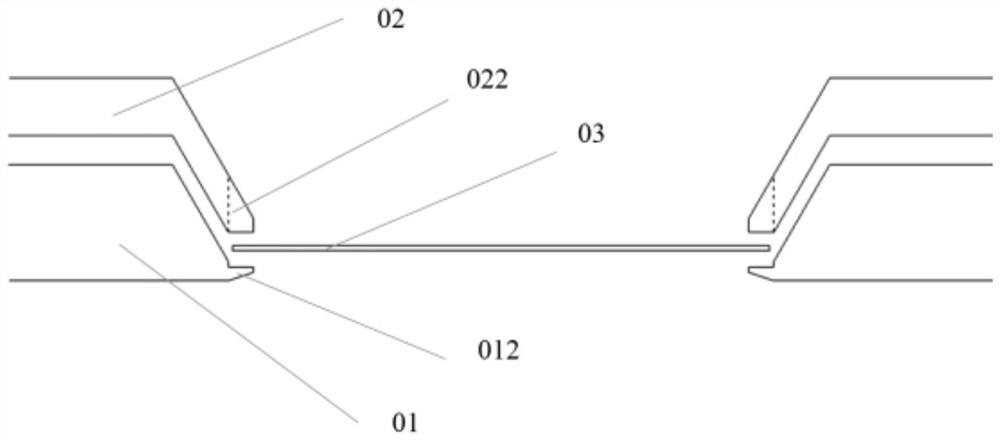

[0035] The upper tray 02 is designed with a single hollow piece, such as image 3 As shown, the hollowed out piece is fully open and hollowed out, which is convenient for double-sided coating. The corresponding lower tray 01 is designed as follows Figure 4 As shown, the middle of the lower tray 01 is designed to be fully open and hollowed out.

specific Embodiment 2

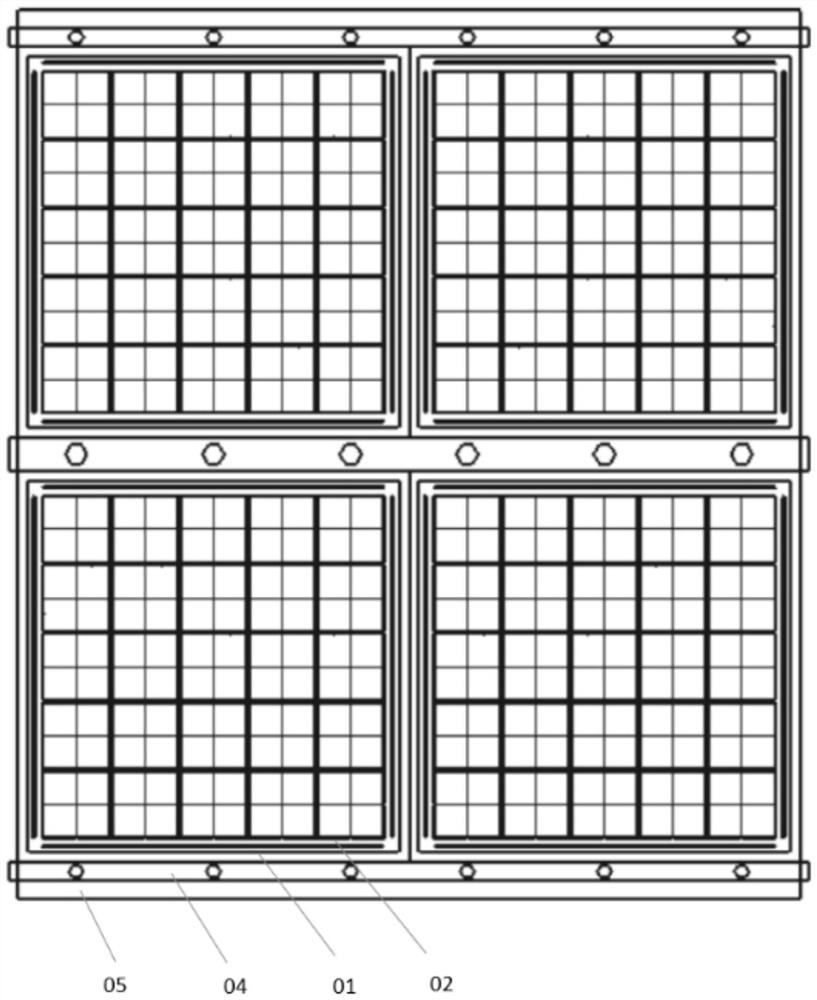

[0037] The upper tray 02 is designed with a plurality of hollowed-out slots, which are regularly arranged in a fully-opened hollow shape, such as Figure 5 As shown, the corresponding lower tray 01 is designed as Image 6 As shown, the middle of the lower tray 01 is designed as a regular arrangement of fully open hollows.

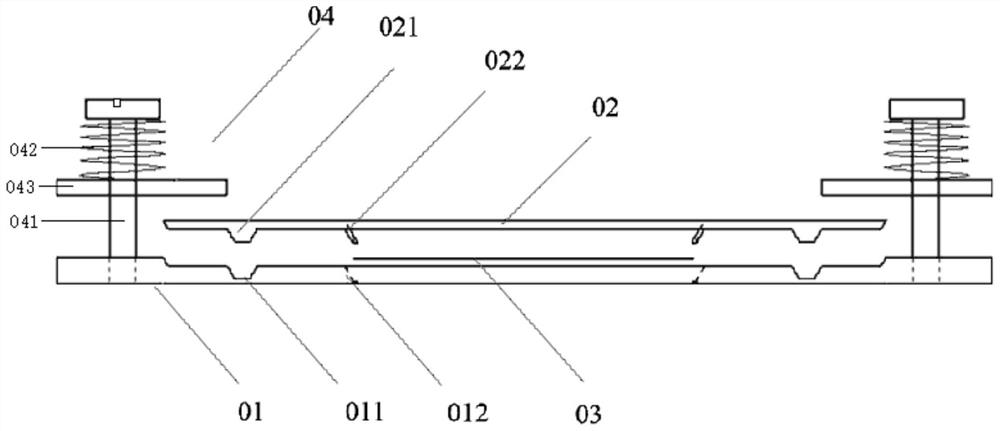

[0038] When a substrate fixture for vertical double-sided coating of the present invention is in operation, after the substrate 03 is placed on the lower tray 01, force is applied to the baffle 043 of the clamping device 04, and the upper compression spring 042 leaves a space, and the upper The tray 02 can be moved into the corresponding position in parallel, the trapezoidal boss 021 fits with the trapezoidal groove 011, the upper tray 02 and the lower tray 01 fit together, the base plate 03 is fixed in the middle position by the edge stoppers and four corner stoppers of the two trays, draw To remove the force applied to the baffle 043, the baffle 043 clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com