Magnetically controlled optical coating equipment

A technology of optical coating and coating equipment, which is applied in the directions of sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of reducing coating efficiency and slow vacuum environment creation speed, so as to improve coating efficiency and facilitate double Surface coating, quick adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

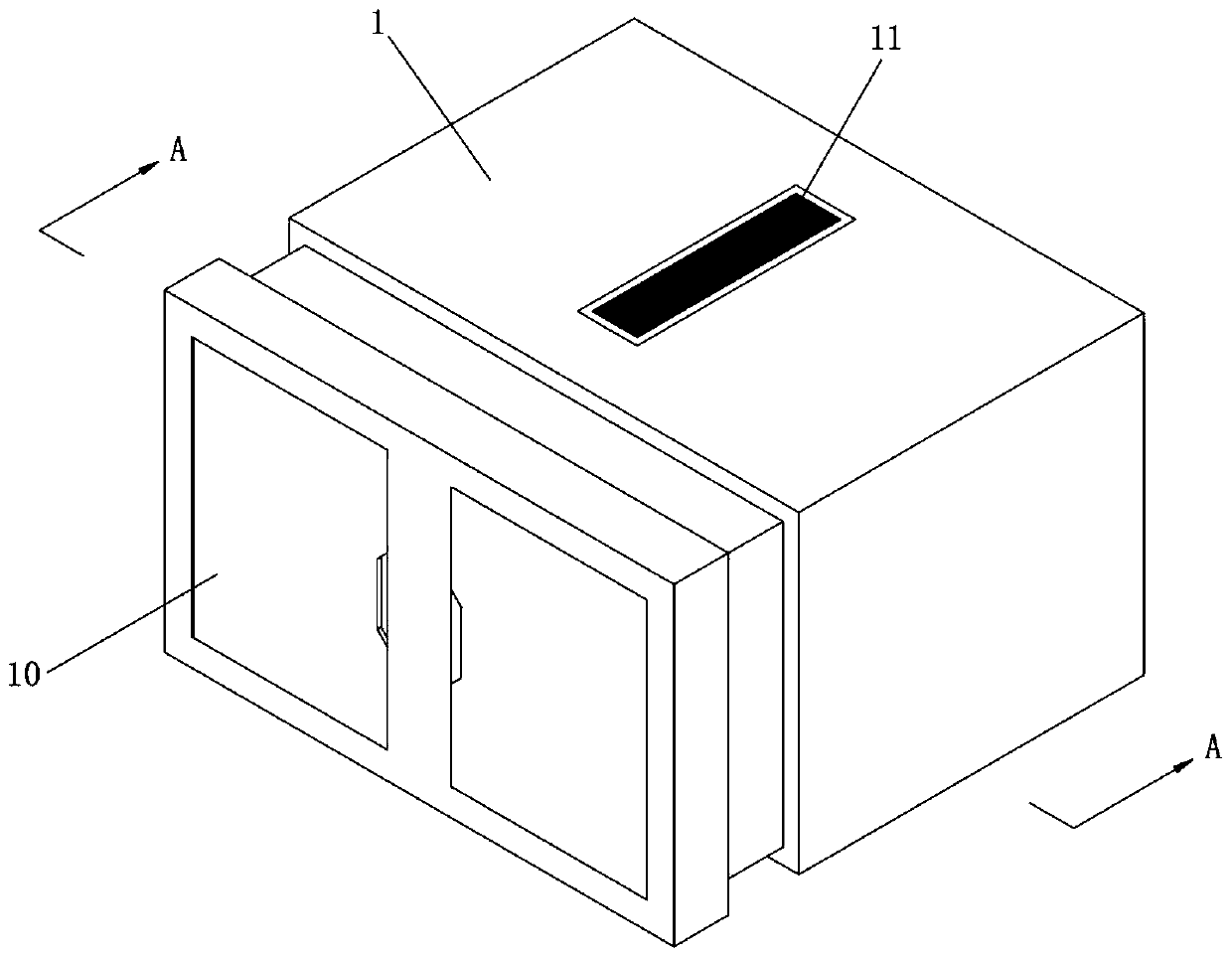

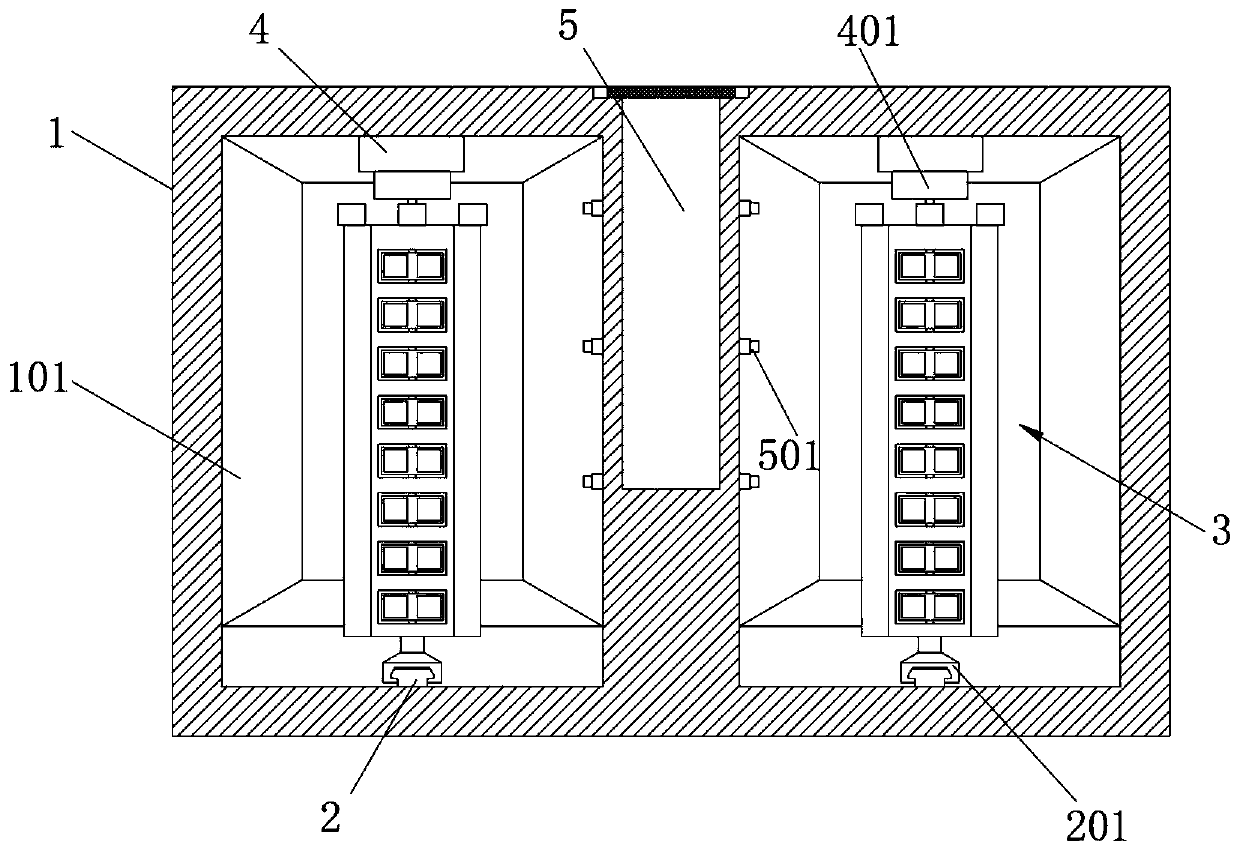

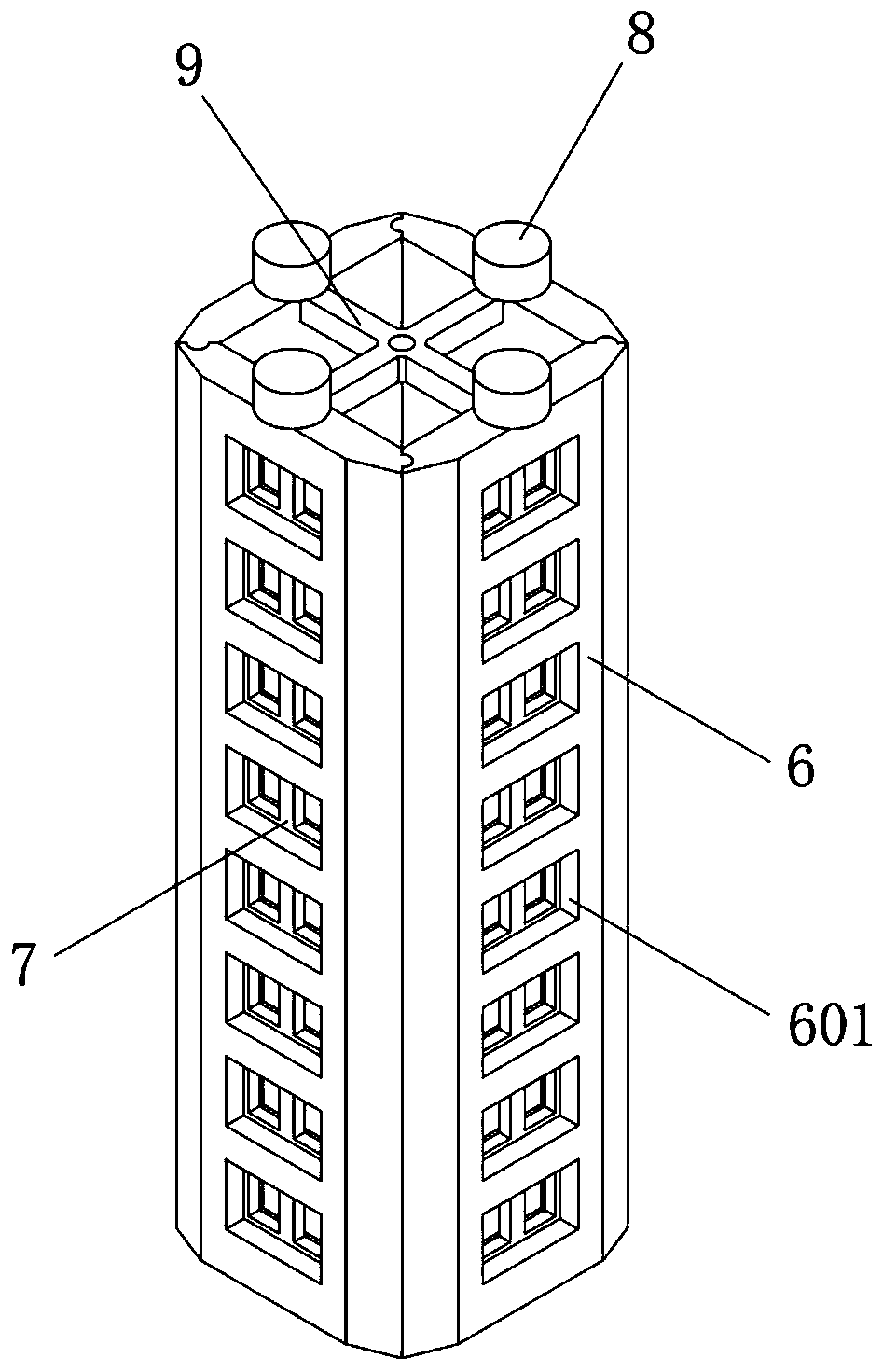

[0021] like Figure 1-4 A kind of magnetron optical coating equipment shown, comprises the coating equipment main body 1 that is cuboid box-shaped structure, is provided with two groups of vacuum chambers 101 that are closed by vacuum sealing door 10 in described coating equipment main body 1, and inside described vacuum chamber 101 A coating system is provided (in practice, the coating system can be any coating equipment, which uses electrons or high-energy lasers to bombard the target, and makes the surface components be sputtered out in the form of atomic groups or ions, and finally deposited on the substrate surface , go through the film forming process, and finally form a thin film; in the target selection, preferably a silicon target, a niobium oxide target and an aluminum target) and a coating support 3 installed in conjunction with the piece to be coated, the bottom of the coating support 3 is supported by a guiding structure, and The top of the coating support 3 is co...

Embodiment 2

[0029] like Figure 1-2A kind of magnetron optical coating equipment shown, comprises the coating equipment main body 1 that is cuboid box-shaped structure, is provided with two groups of vacuum chambers 101 closed by vacuum sealing door 10 in described coating equipment main body 1, and the vacuum chambers of two groups The center of 101 is provided with a group of vacuum pump chambers 5 for the installation of vacuum pump groups. Cooperate with the vacuum pump tube 501 of the pump set.

[0030] Specifically, the vacuum pump set in the vacuum pump chamber 5 includes a plurality of molecular pumps, a set of roughing pumps, a set of Roots pumps and a set of maintenance pumps.

[0031] Specifically, the magnetron optical coating equipment uses molecular pumps, rough pumps, Roots pumps and maintenance pumps to achieve vacuuming of the vacuum chambers 101 on both sides. The pump uses the VSN6501 type roughing pump, the Roots pump uses the NB2400B type Roots pump, and the mainten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com