Metal perforated acoustic board

A metal perforated, sound-absorbing panel technology, applied in building components, sound insulation, covering/lining, etc., can solve problems such as limited use range, affect interior decoration effects, interfere with acoustic effects, etc., to improve sound absorption and decorative effects. , The effect of low requirements on preparation equipment and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

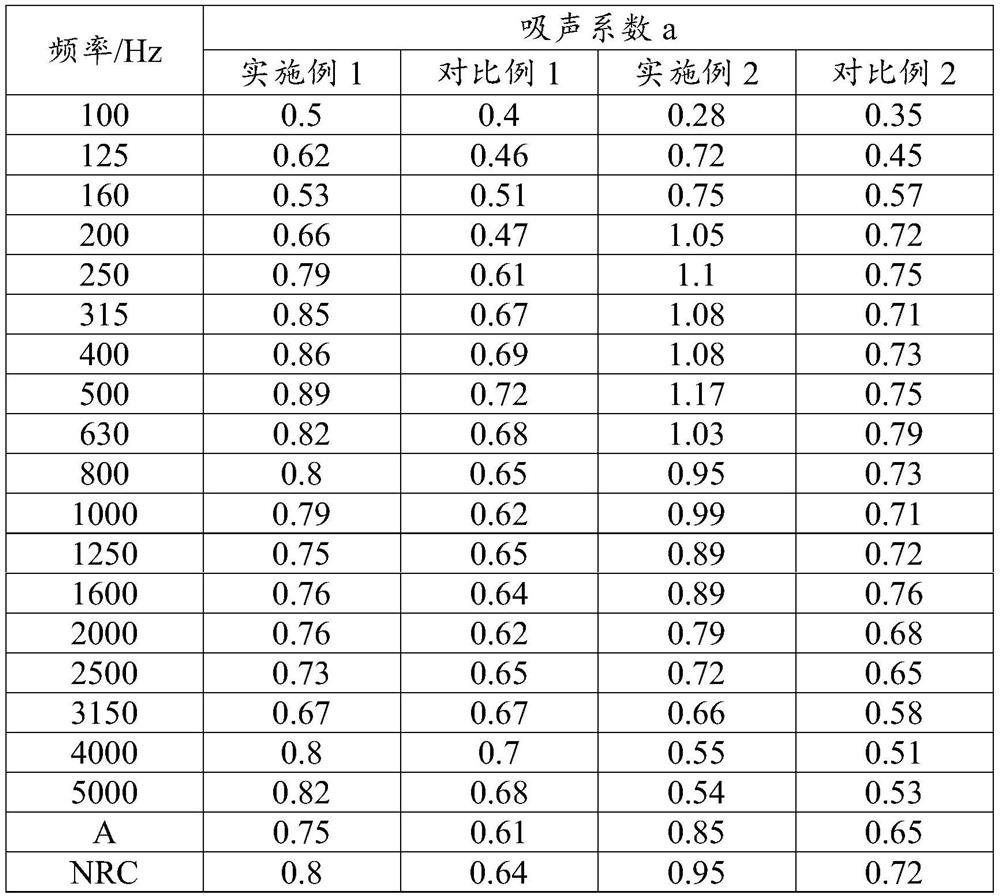

Embodiment 1

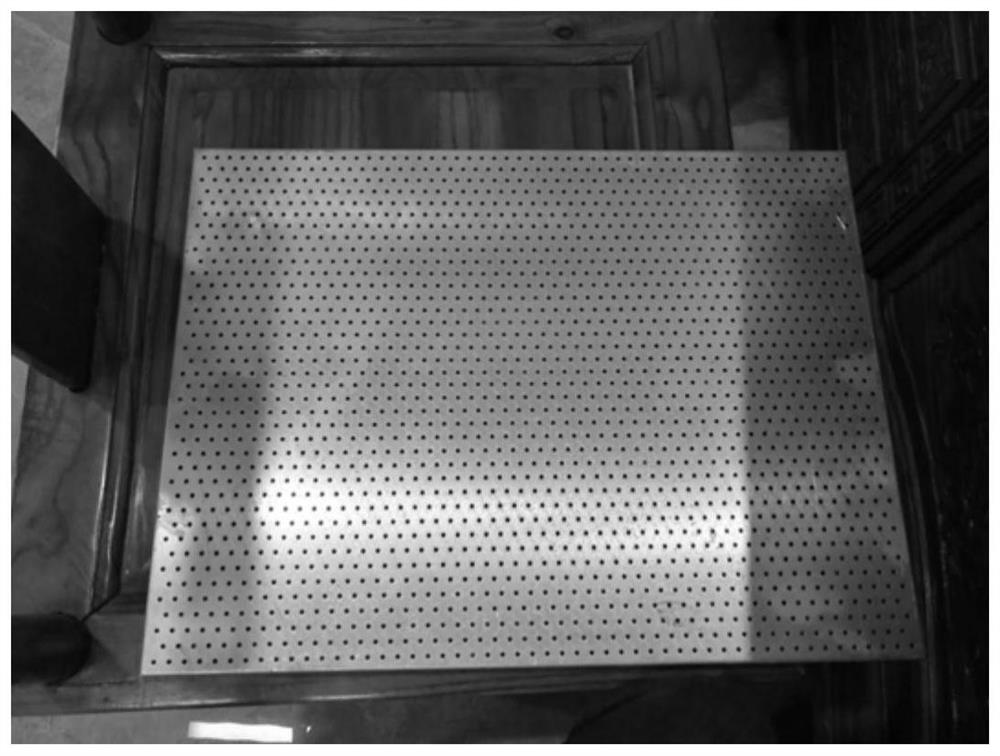

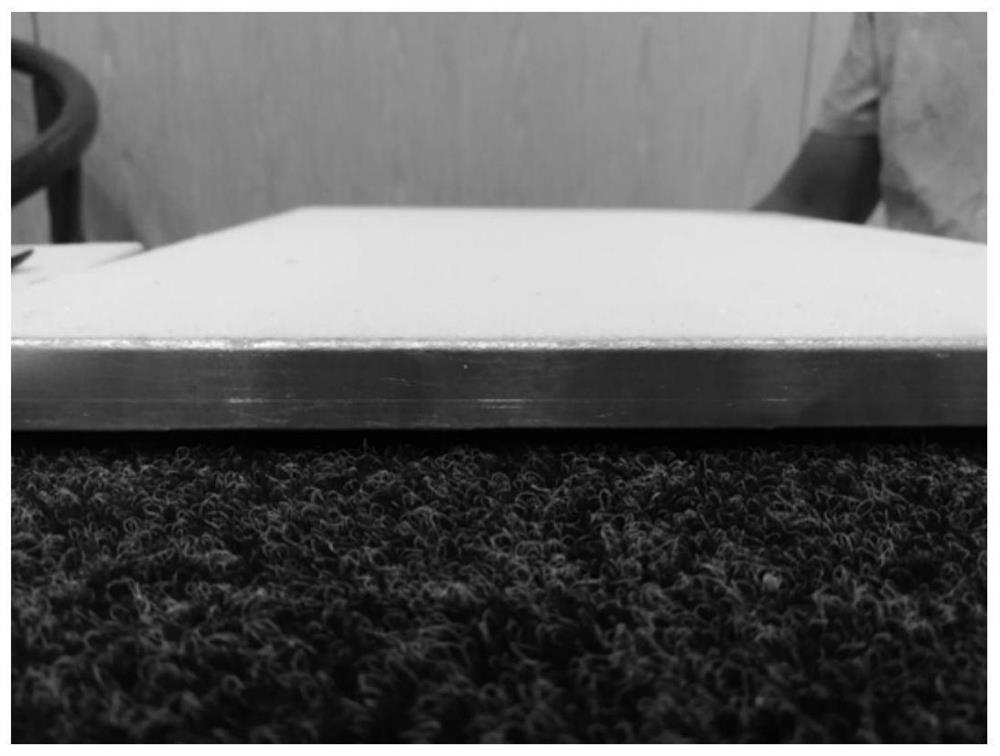

[0022] An embodiment of a metal perforated sound-absorbing panel described in the present invention.

[0023] The metal perforated sound-absorbing panel described in this embodiment comprises a metal perforated plate layer and a sandstone sound-absorbing layer; the thickness of the sandstone sound-absorbing layer is 3mm; the thickness of the metal perforated sound-absorbing panel is 10mm; The hole spacing on the surface of the metal perforated plate layer is 5 mm, and the aperture is 2 mm; the metal perforated plate layer is an aluminum perforated plate layer; the surface of the metal perforated plate layer is frosted; the sandstone sound-absorbing layer is passed through The slurry prepared from silicate-like sandstone is scraped or sprayed on the surface of the metal perforated board layer; the surface density of the metal perforated sound-absorbing board is 22.3kg / m 2 .

[0024] The preparation method of the metal perforated sound-absorbing panel described in this example:...

Embodiment 2

[0027] An embodiment of a metal perforated sound-absorbing panel described in the present invention.

[0028] The metal perforated sound-absorbing panel described in this embodiment comprises a layer of metal perforated sound-absorbing layer and a layer of sandstone sound-absorbing layer; the thickness of the sandstone sound-absorbing layer is 2mm; the thickness of the metal perforated sound-absorbing panel is 8mm; The hole spacing on the surface of the metal perforated plate layer is 10 mm, and the aperture is 5 mm; the metal perforated plate layer is an aluminum perforated plate layer; the surface of the metal perforated plate layer is frosted; the sandstone sound-absorbing layer is passed through The slurry prepared from silicate-like sandstone is scraped or sprayed on the surface of the metal perforated board layer; the surface density of the metal perforated sound-absorbing board is 13kg / m 2 .

[0029] The preparation method of the metal perforated sound-absorbing panel ...

Embodiment 3

[0031] An embodiment of a metal perforated sound-absorbing panel described in the present invention.

[0032] The metal perforated sound-absorbing panel described in this embodiment comprises a layer of metal perforated plate and a layer of sandstone sound-absorbing layer; the thickness of the sandstone sound-absorbing layer is 2mm; the thickness of the metal perforated sound-absorbing panel is 15mm; The hole spacing on the surface of the metal perforated plate layer is 10 mm, and the aperture is 10 mm; the metal perforated plate layer is an aluminum perforated plate layer; the surface of the metal perforated plate layer is frosted; the sandstone sound-absorbing layer is passed through The slurry prepared from silicate-like sandstone is scraped or sprayed on the surface of the metal perforated board layer; the surface density of the metal perforated sound-absorbing board is 15kg / m 2 .

[0033] The preparation method of the metal perforated sound-absorbing panel described in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com