Sound wave monitoring system of pump and method

A monitoring system and sound wave technology, applied in the direction of measuring ultrasonic/sonic/infrasonic waves, pump control, measuring devices, etc., can solve the problems of unable to monitor the running state of water pumps, and achieve the effects of low cost, low failure rate and high detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

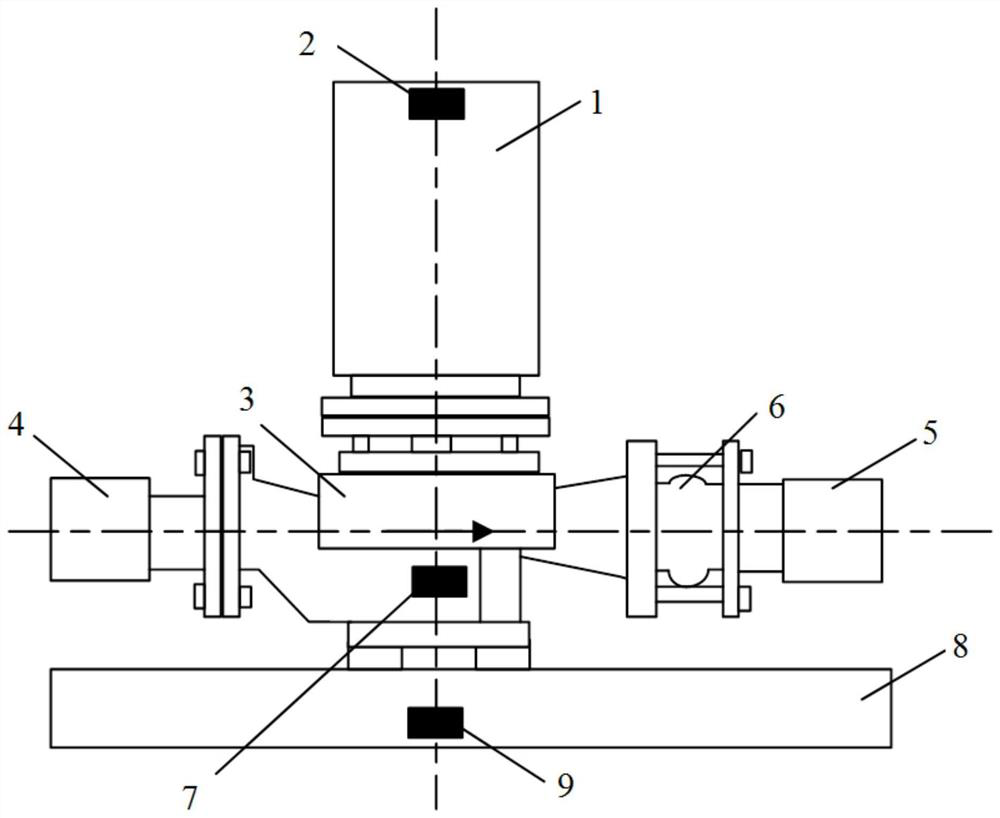

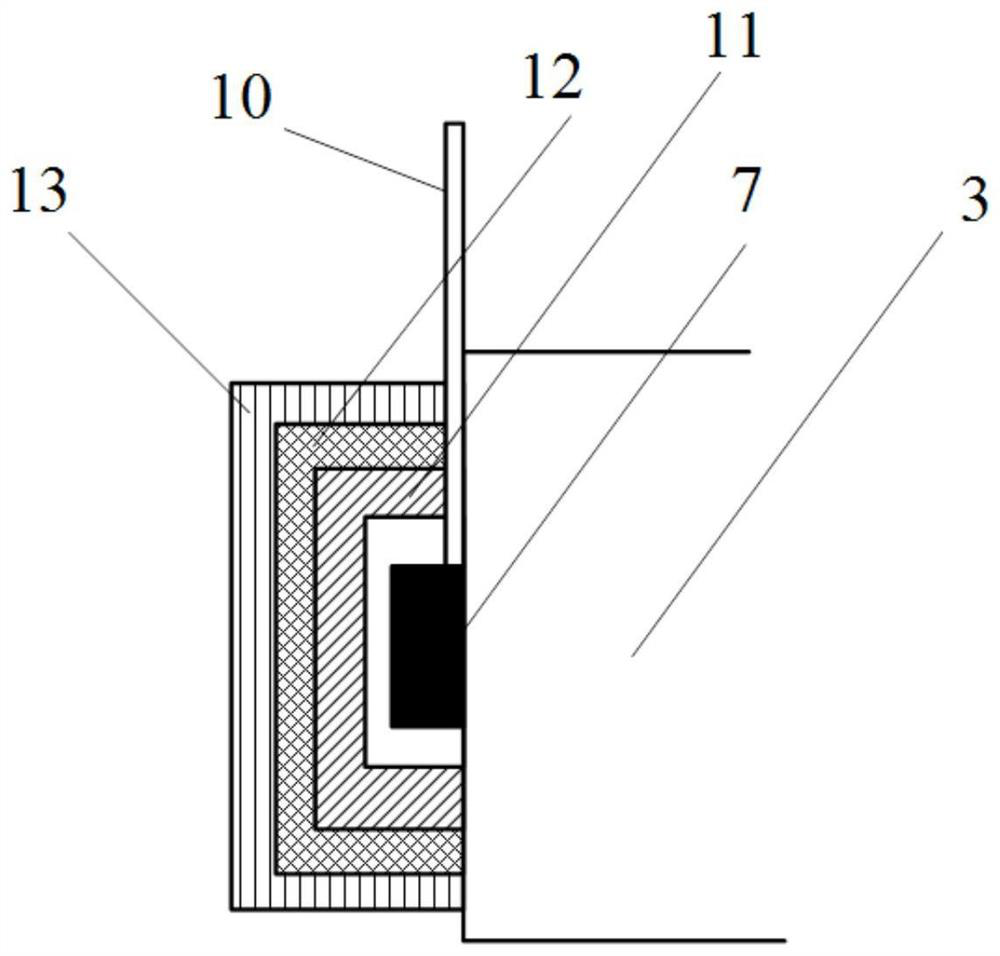

[0044] refer to figure 1, a pump sound wave monitoring system, including pump equipment, sound wave sensor, sound wave signal transmission cable and network, sound wave data analysis platform and sound wave monitoring system platform; the sound wave sensor is used to collect the sound wave signal of the pump in real time, and the collected pump The sound wave signal is transmitted to the sound wave data analysis platform and sound wave monitoring system platform through the sound wave signal transmission cable and network. The sound wave data analysis platform is used for filtering, extracting characteristic parameters, and sending valuable data to the sound wave detection platform. According to the sound wave signal of the pump, the sound wave monitoring system platform analyzes the working state of the pump (running or stopping), whether leakage or internal leakage occurs, and analyzes the corresponding relationship between the sound wave signal of the pump and the pump speed...

Embodiment 2

[0056] A monitoring method based on the above-mentioned pump acoustic monitoring system, comprising the following steps:

[0057] S1: According to the type of fluid pipeline and the type of pump, such as tap water pipeline, or natural gas pipeline, or directly buried thermal insulation heating pipeline, or oil pipeline, the pump is positive displacement pump, centrifugal pump, axial flow pump, mixed flow pump or magnetic pump According to different types of pumps, choose the appropriate installation position of the acoustic wave sensor, install the acoustic wave sensor on the existing pump, or directly replace the existing pump equipment with the pump with the acoustic wave sensor.

[0058] S2: Carry out geographic information coding (GIS coding, that is, the installation location and equipment number) of each pump equipment equipped with an acoustic sensor, that is, obtain its coordinate value in the geographic information system, for example: latitude and longitude coordinate...

Embodiment 3

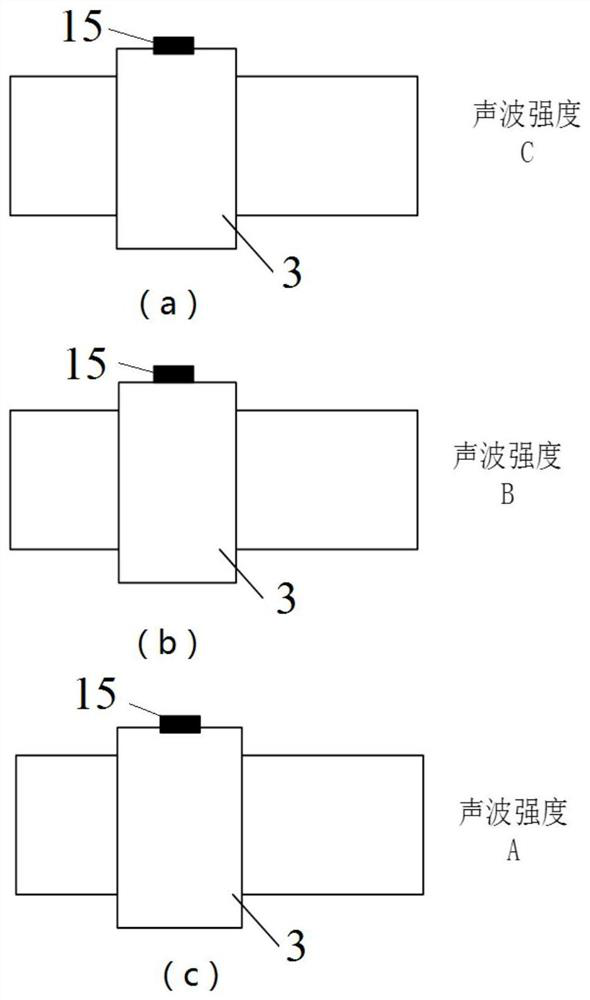

[0062] A monitoring method based on the above-mentioned pump acoustic monitoring system, which indirectly realizes flow monitoring, includes the following steps:

[0063] S1: According to the speed control pump model and its structure, select the appropriate acoustic wave sensor and its installation position on the pump;

[0064] S2: Install this type of pump and its acoustic sensor on the flow calibration experiment platform;

[0065] S3: Debug the speed-regulating pump and its various sensors and the data acquisition system of the flow calibration experiment platform, so as to eliminate the noise interference and acquire the sound wave signal of the qualified sound wave sensor to meet the calibration requirements;

[0066] S4: Debug the pressure sensor before and after the pump of the speed regulating pump, and the flow sensor of the calibration experiment platform to meet the calibration requirements;

[0067] S5: Under the conditions of different pump front pressure, diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com