A three-phase alternating current transferred arc plasma heating and melting method and system

A plasma, three-phase AC technology, applied in lighting and heating equipment, furnace types, furnaces, etc., can solve the problems of high cost, insufficient energy utilization, low heat transfer efficiency, etc., and achieve high material processing rate and service life. And the effect of low cost of use and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] A three-phase alternating current transfer arc plasma heating and melting method of the present invention comprises the following steps:

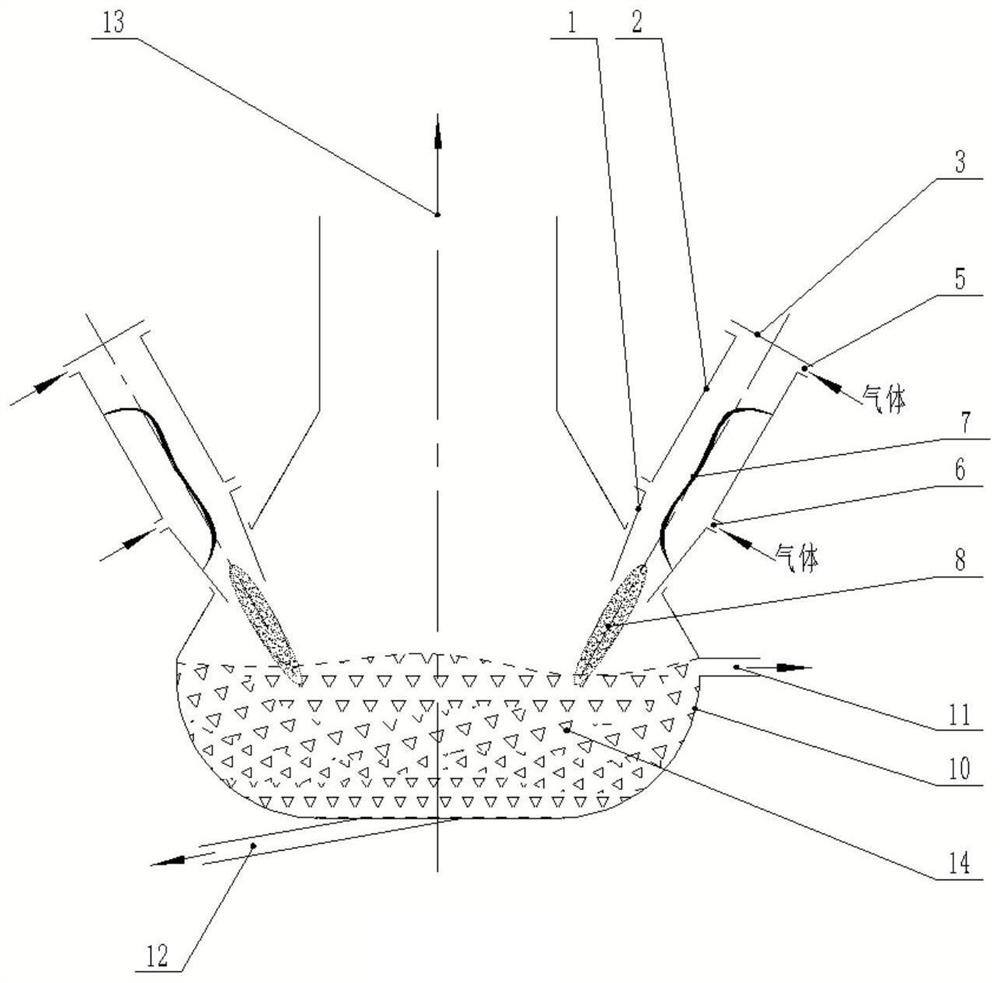

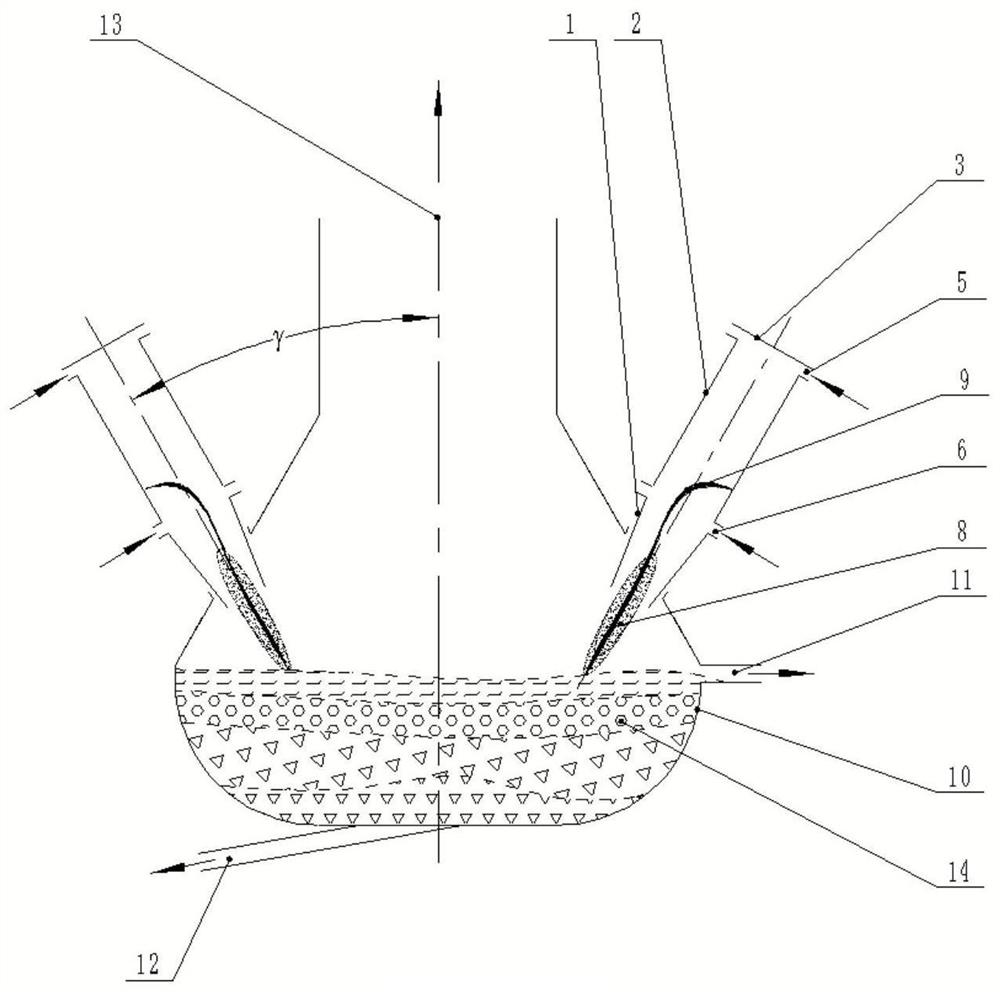

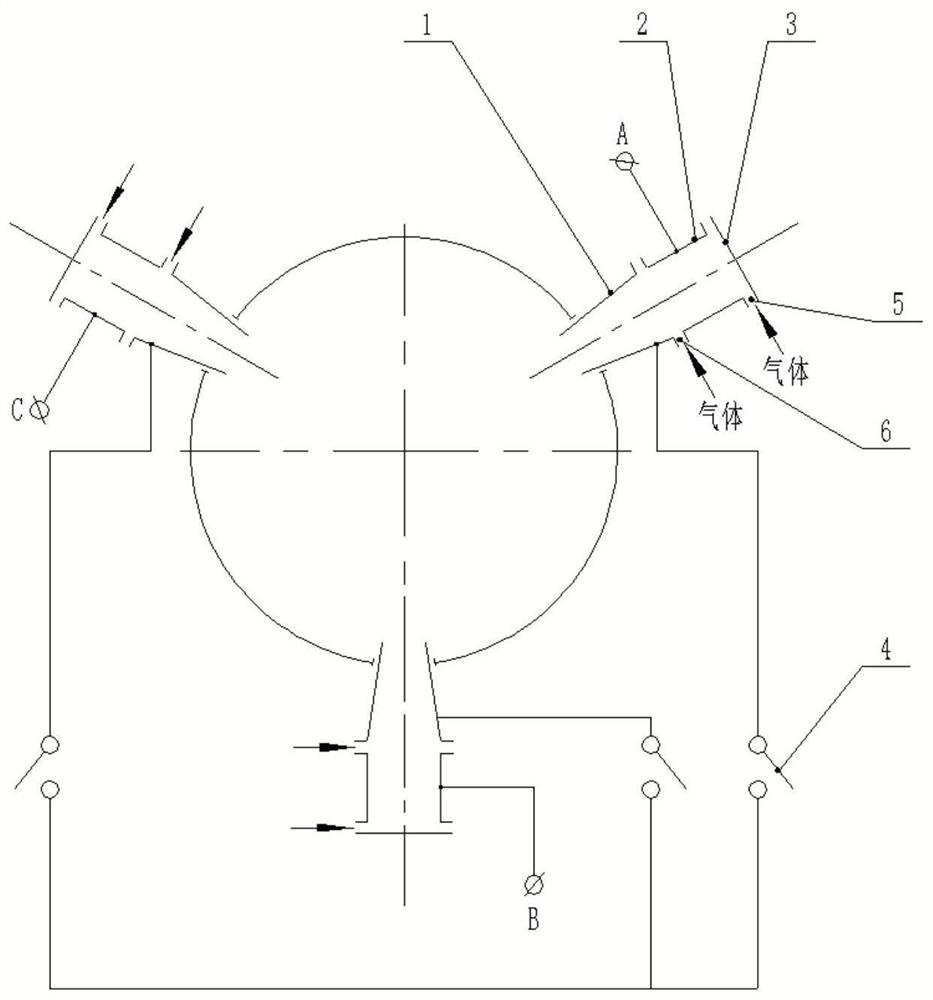

[0022] The three AC arc plasma generator nozzles are connected to each other, and the AC arc electrodes and their corresponding nozzles break down and start arcs. A plasma flame is formed, and the plasma flame is in contact with the surface layer of the material to be processed, so that the surface layer of the material is gradually heated and melted. This step is the pre-melting stage of the non-transfer arc material;

[0023] After the surface layer of the material to be processed is pre-melted into a liquid state, the three nozzles (auxiliary electrodes) are disconnected, and the arc root on the nozzle moves downstream under the action of pneumatic force, extending to the surface of the pre-melted material, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com