Method for producing hydrogenated nitrile rubber and hnbr compositions thereof

A technology of hydrogenated nitrile rubber and nitrile rubber, applied in the field of hydrogenated nitrile rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

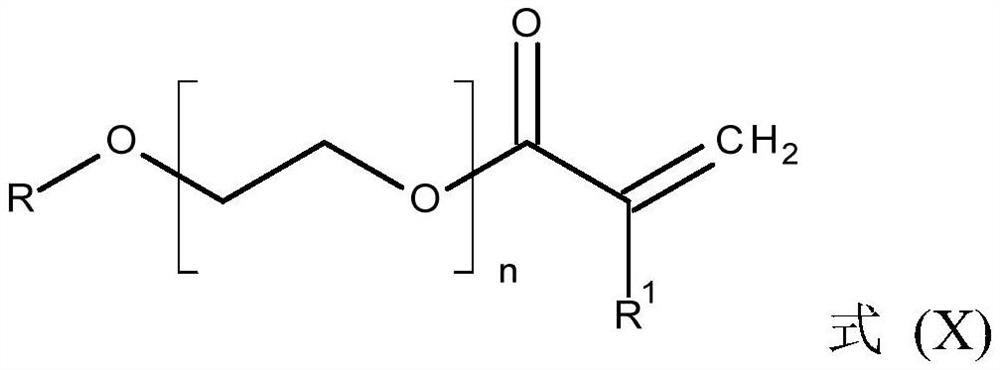

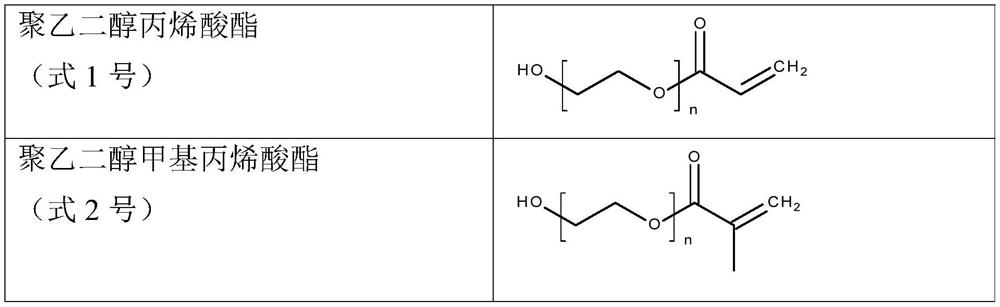

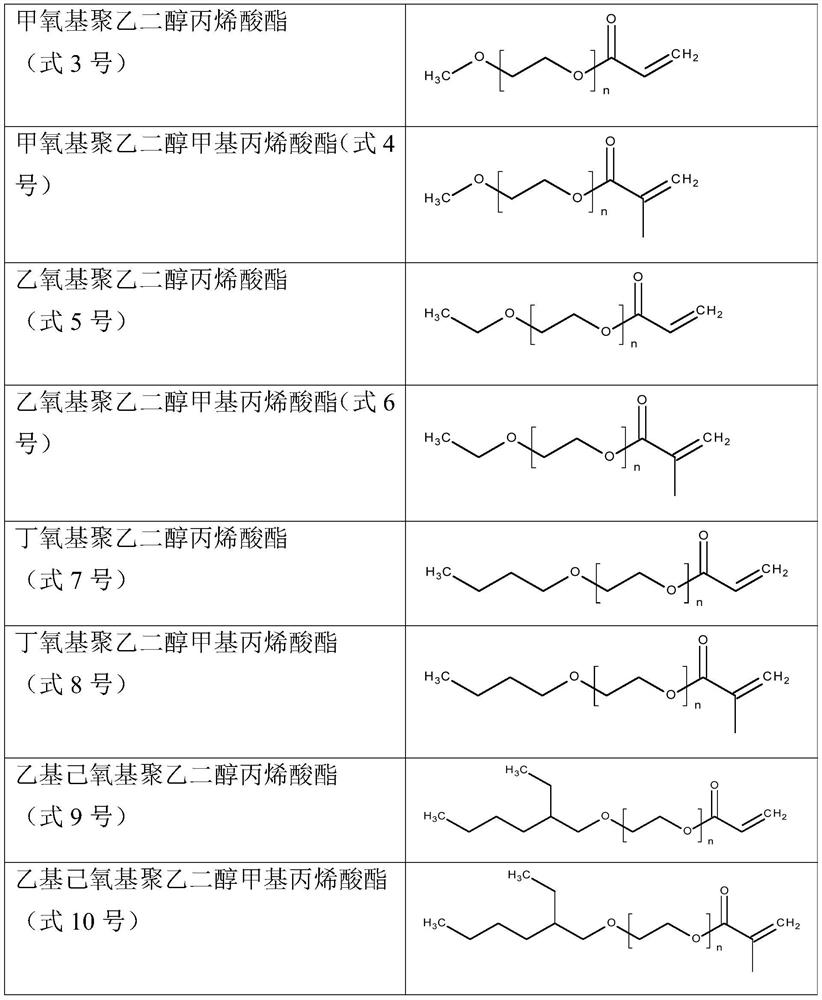

Method used

Image

Examples

example

[0133] materials used

[0134]

[0135] mooney aging

[0136] To assess Mooney aging, the change in Mooney viscosity was measured after an exemplary aging process. The values for the Mooney viscosity (ML1+4 at 100° C.) were determined in each case by means of a shear disc viscometer according to ASTM D1646-07. Two test samples were cut from the rubber. Place the sample to be aged on the intermediate rack in an air-circulating drying oven heated to 140 °C. The samples were kept at 140°C for 4 days in the air circulating drying oven.

[0137] Mooney viscosities were determined from unaged and aged samples. ΔMV is derived from the difference between the measured values of aged and unaged samples.

[0138] gel content

[0139] In about 20 ml of methyl ethyl ketone (MEK), 0.1 g to 0.2 g of polymer is dispersed or the soluble polymer fraction is dissolved. After 18 hours, the insoluble dispersed fraction was precipitated by centrifugation (25 000 rpm), the supernatant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com