Nutritional health-care product for regulating immune function

A technology for nutritional health products and immune regulation, which is applied to the functions of food ingredients, food ingredients, and food drying. It can solve the problems of non-continuous preparation of soybean peptides and troublesome transfer processes, and achieve convenient preparation and improved enzymatic hydrolysis rate. , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

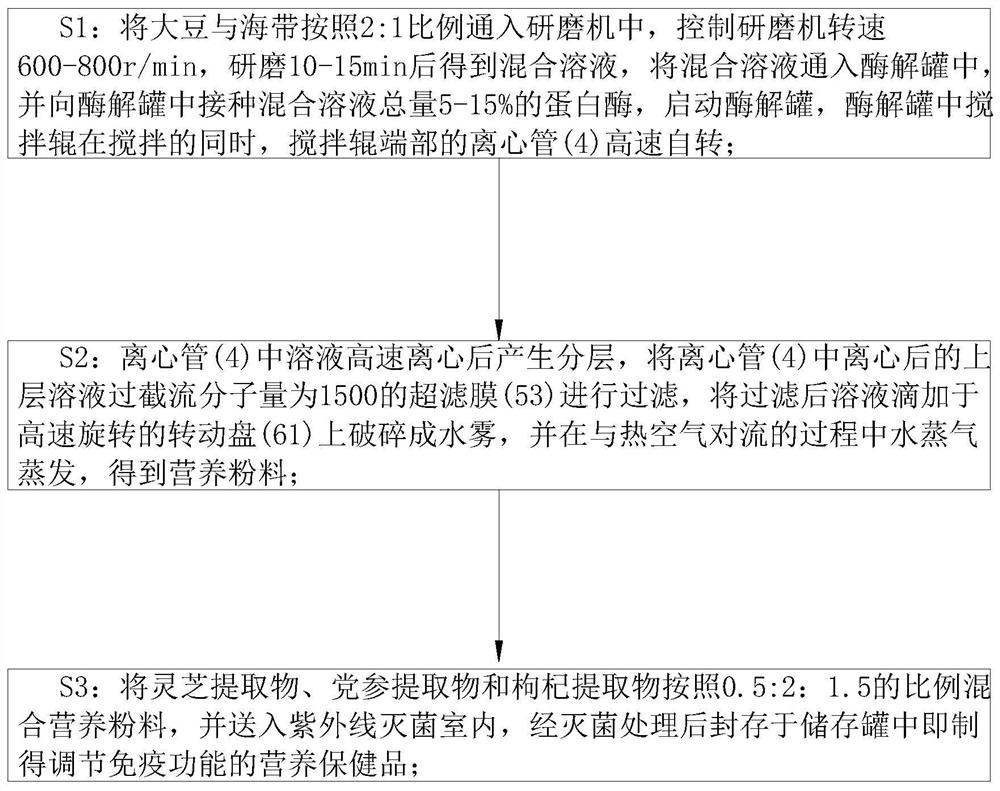

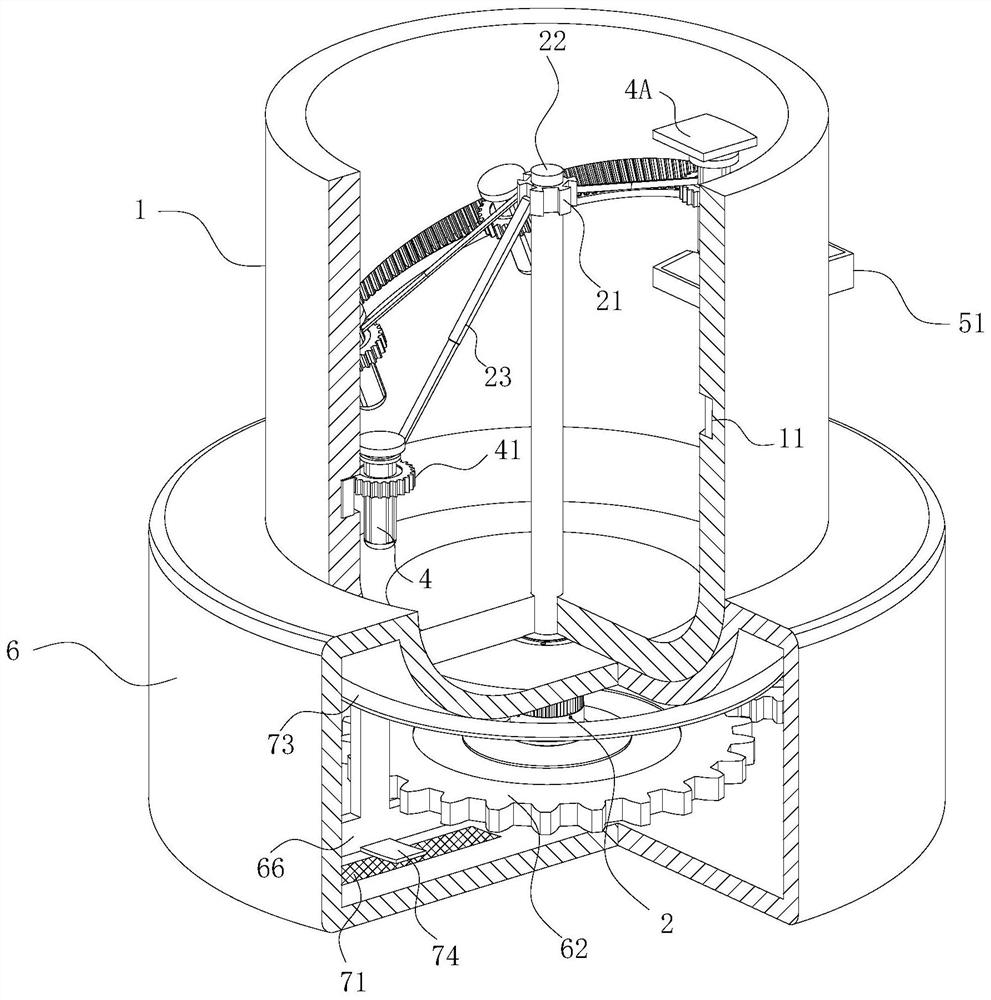

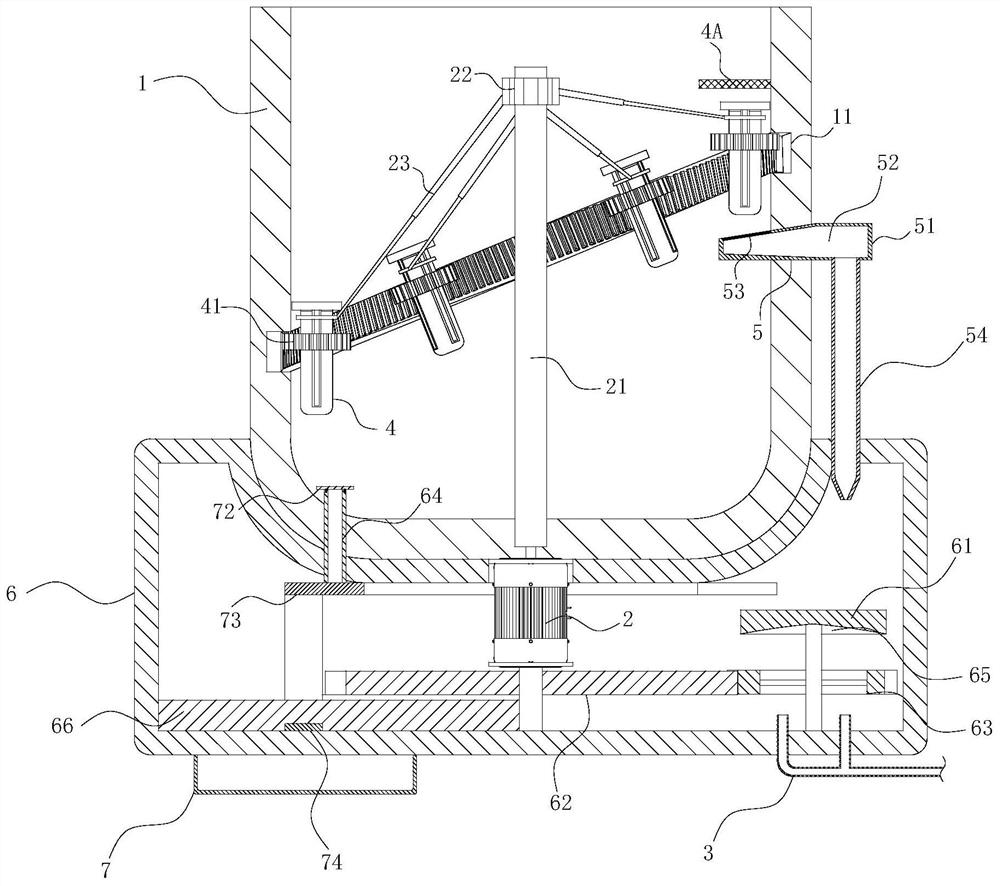

[0027] Such as Figure 1 to 4 As shown, the preparation method of the modulated immune function of the nutritional health product of the modulated immune function includes the following steps:

[0028] S1: In accordance with the 2: 1 proportion of soybeans into the grinder, control the grinding machine speed 600-800r / min, and the mixed solution is obtained, and the mixed solution is introduced into the enzyme, and the enzymatic solution The total amount of the mixed solution in the tank is inoculated with a total amount of 5-15% protease, activation enzyme, and the mixing roll in the enzyme solution tank while stirring, the centrifuge tube of the end portion of the mixing roller is rotated.

[0029] S2: After centrifugation in the centrifuge tube, a layered is produced after centrifugation, and the ultrafiltration membrane having a centrifuge in the centrifuge tube is filtered over the ultrafi molecular weight of 1500, and after filtration, the solution is added to the high-speed...

Embodiment approach

[0034] As an embodiment of the present invention, the first slider 42 "T" shape is designed; the first slide groove 42 "T" shape is closest to the centrifuge tube 4 inner cavity; the sealing cover 44 is close to the centrifuge 4 is fixedly connected with a side extrusion bladder 45; the first chute 42 near the side tube 4 is fixedly connected with a inflatable bladder 46; pressing the bladder 45 and the inflatable bladder 46 through the conduit pipe design; the slide The bottom of the plate 43 is elastically connected to the first slide 42; when operating, when the sealing cover 44 is separated from the centrifuge tube 4, thereby reducing the extrusion cap 45 below the sealing cover 44, which The capping 45 restores the shape of the gas in the expansion bladder 46 to turn the first slide groove 42, when the centrifuge 4 is disengaged from the water surface, the sealing cover 44 off the buoyancy, the slide plate 43 and the sealing cover 44 to the centrifuge tube under the action of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com