Artificial fiberboard drying tail gas treatment system

A treatment system and tail gas drying technology, applied in gas treatment, gaseous effluent wastewater treatment, filtration treatment, etc., can solve the problems of large amount of exhaust gas, low temperature, high humidity, etc., to save water and avoid secondary pollution The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be further described in detail below.

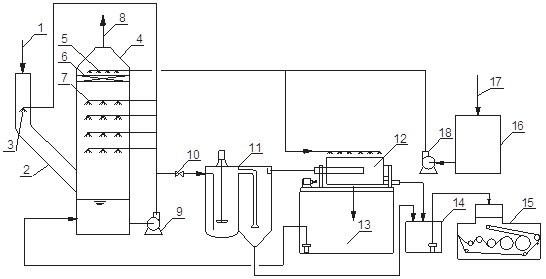

[0027] The present invention deals with the tail gas produced in the production process of wood-based panel glue production. The dry tail gas produced in the process of wood-based panel production contains fine fibers, boiler flue gas dust and volatile free formaldehyde, which cannot be directly discharged. The tail gas treatment system is used to treat the tail gas.

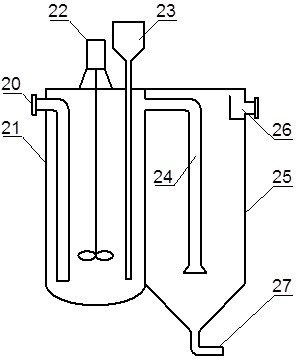

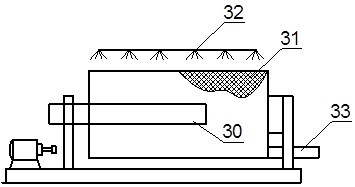

[0028] The man-made fiberboard drying tail gas treatment system of the present invention comprises an absorption tower 4 and a tail gas inlet pipe 2 connected thereto, an inlet pipe cleaning nozzle 3 is arranged in the inlet pipe of the absorption tower, and a multi-layer washing nozzle is arranged in the absorption tower 4 The nozzle and the liquid outlet of the absorption tower are arranged at the bottom of the absorption tower 4 and connected to the inlet of the absorption tower circulation pump 9, the outlet of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com