Czochralski method-based crystal growth interface shape detection method and device

A technology of crystal growth and detection method, applied in the direction of crystal growth, single crystal growth, self-melt pulling method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

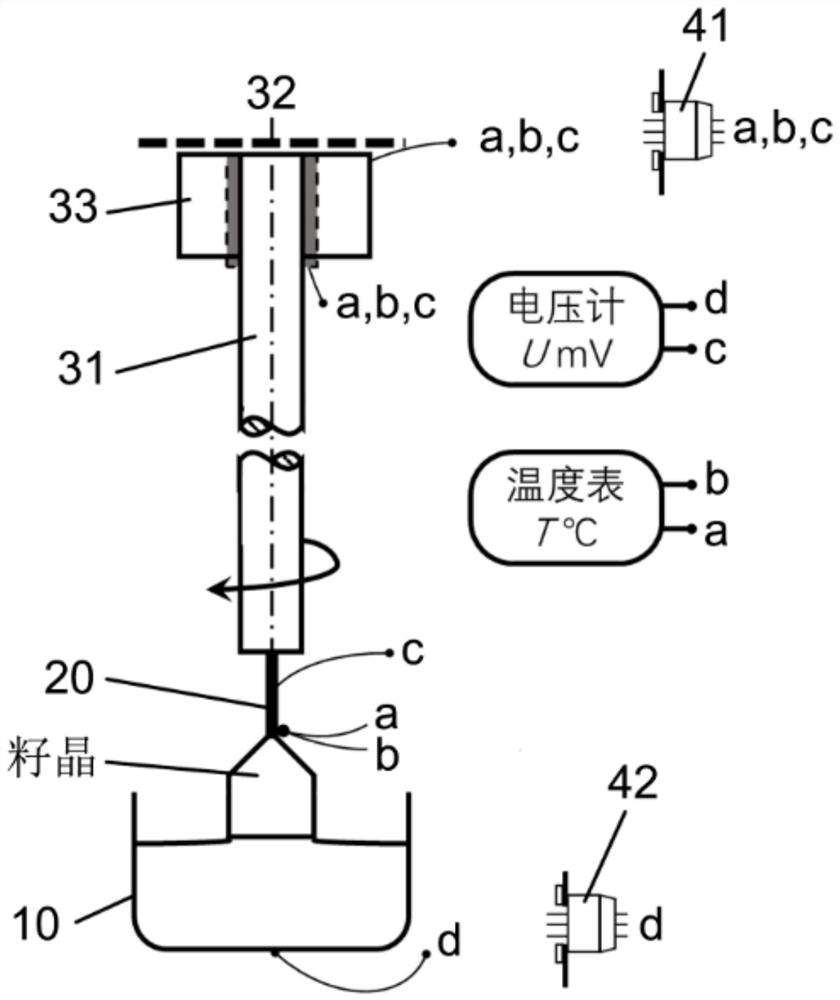

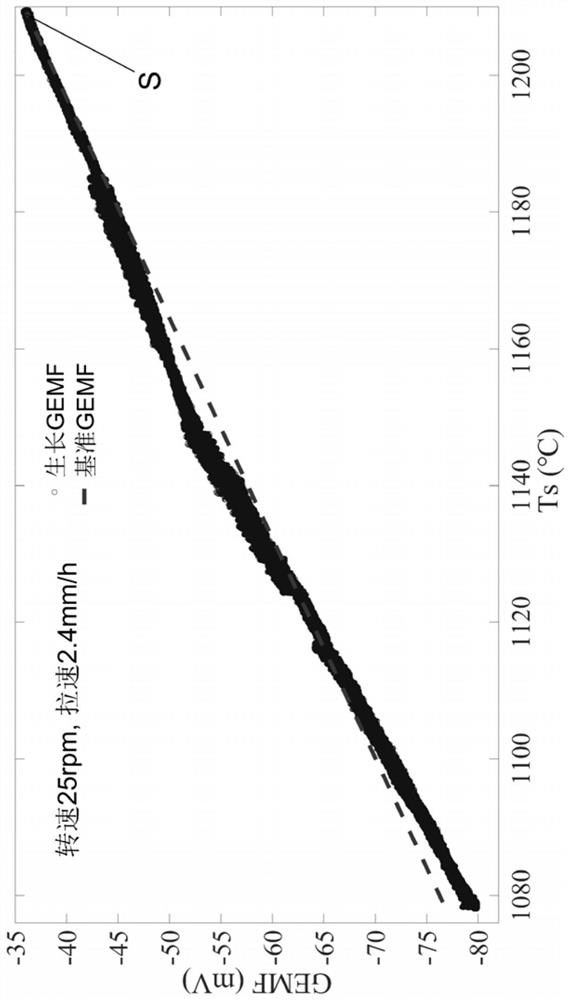

[0048] Using the detection method and device of the present invention, the shape of the growth interface during the growth of lithium niobate crystals can be detected in real time, combined with figure 1 and figure 2 Be explained.

[0049] via figure 1 The four leading wires numbered a, b, c and d shown in the figure lead out the electrical signals of the seed crystal temperature and the interface electromotive force at the end of the constantly rotating and rising high-temperature seed crystal, and display them in the thermometer and voltmeter respectively in real time , record, summarize, plot into figure 2 (with the seed temperature T as the horizontal axis and the interface electromotive force U as the vertical axis) T-U curve. The whole process of crystal growth by the pulling method includes six stages in sequence: heating, crystal dropping, shouldering, equal diameter, pulling off, and cooling. The detection method of the present invention is mainly used in the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com