Device and method for enhancing oxidative degradation of organic waste gas

A technology for organic waste gas and oxidative degradation, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of high cost and low efficiency of organic waste gas degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

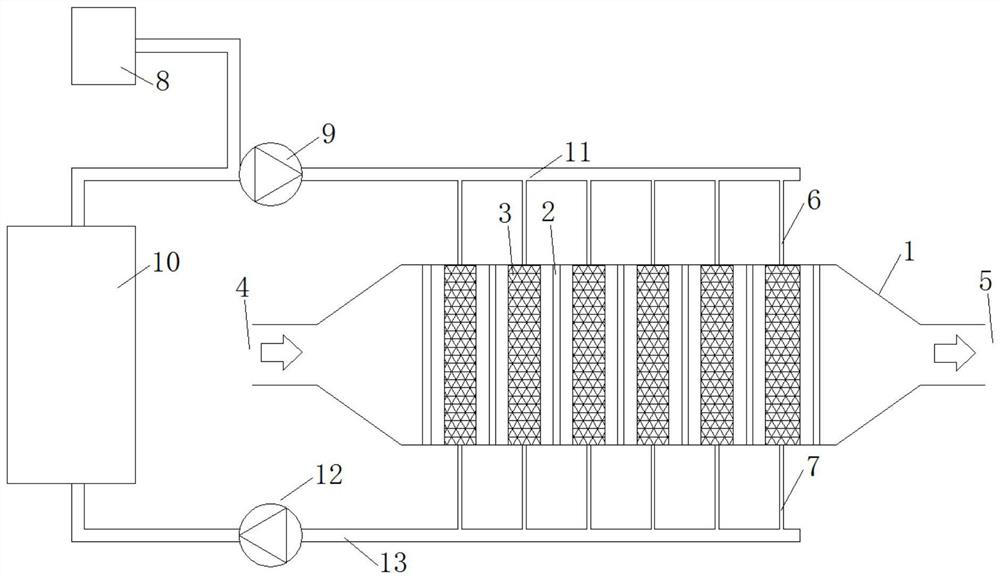

[0023] See attached figure 1 . A device for enhancing the oxidative degradation of organic waste gas, comprising a box body 1, several ultraviolet lamp tubes 2 and several catalytic components 3; one end of the box body 1 is provided with a waste gas inlet 4, and the other end is provided with a waste gas outlet 5; The box body 1 is provided with several catalytic assemblies 3 arranged sequentially along the path from the exhaust gas inlet 4 to the exhaust gas outlet 5; several ultraviolet lamp tubes 2 and several catalytic assemblies 3 are arranged alternately; the top of each catalytic assembly 3 corresponds to An ozone water delivery branch pipe 6 is provided, and an ozone water recovery branch pipe 7 is correspondingly provided at the bottom of each catalytic assembly 3 . It can be seen from the above structure that the organic waste gas enters the box body 1 from the waste gas inlet 4; the ozone water infiltrates the corresponding catalytic assembly 3 from the ozone wate...

Embodiment 2

[0025] See attached figure 1 . A device for enhancing the oxidative degradation of organic waste gas, comprising a box body 1, several ultraviolet lamp tubes 2 and several catalytic components 3; one end of the box body 1 is provided with a waste gas inlet 4, and the other end is provided with a waste gas outlet 5; The box body 1 is provided with several catalytic assemblies 3 arranged sequentially along the path from the exhaust gas inlet 4 to the exhaust gas outlet 5; several ultraviolet lamp tubes 2 and several catalytic assemblies 3 are arranged alternately; the top of each catalytic assembly 3 corresponds to An ozone water delivery branch pipe 6 is provided, and an ozone water recovery branch pipe 7 is correspondingly provided at the bottom of each catalytic assembly 3 . It can be seen from the above structure that the organic waste gas enters the box body 1 from the waste gas inlet 4; the ozone water infiltrates the corresponding catalytic assembly 3 from the ozone wate...

Embodiment 3

[0034] See attached figure 1 . A device for enhancing the oxidative degradation of organic waste gas, comprising a box body 1, several ultraviolet lamp tubes 2 and several catalytic components 3; one end of the box body 1 is provided with a waste gas inlet 4, and the other end is provided with a waste gas outlet 5; The box body 1 is provided with several catalytic assemblies 3 arranged sequentially along the path from the exhaust gas inlet 4 to the exhaust gas outlet 5; several ultraviolet lamp tubes 2 and several catalytic assemblies 3 are arranged alternately; the top of each catalytic assembly 3 corresponds to An ozone water delivery branch pipe 6 is provided, and an ozone water recovery branch pipe 7 is correspondingly provided at the bottom of each catalytic assembly 3 . It can be seen from the above structure that the organic waste gas enters the box body 1 from the waste gas inlet 4; the ozone water infiltrates the corresponding catalytic assembly 3 from the ozone wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com