Triazole modified ferric oxide photocatalyst and preparation method thereof

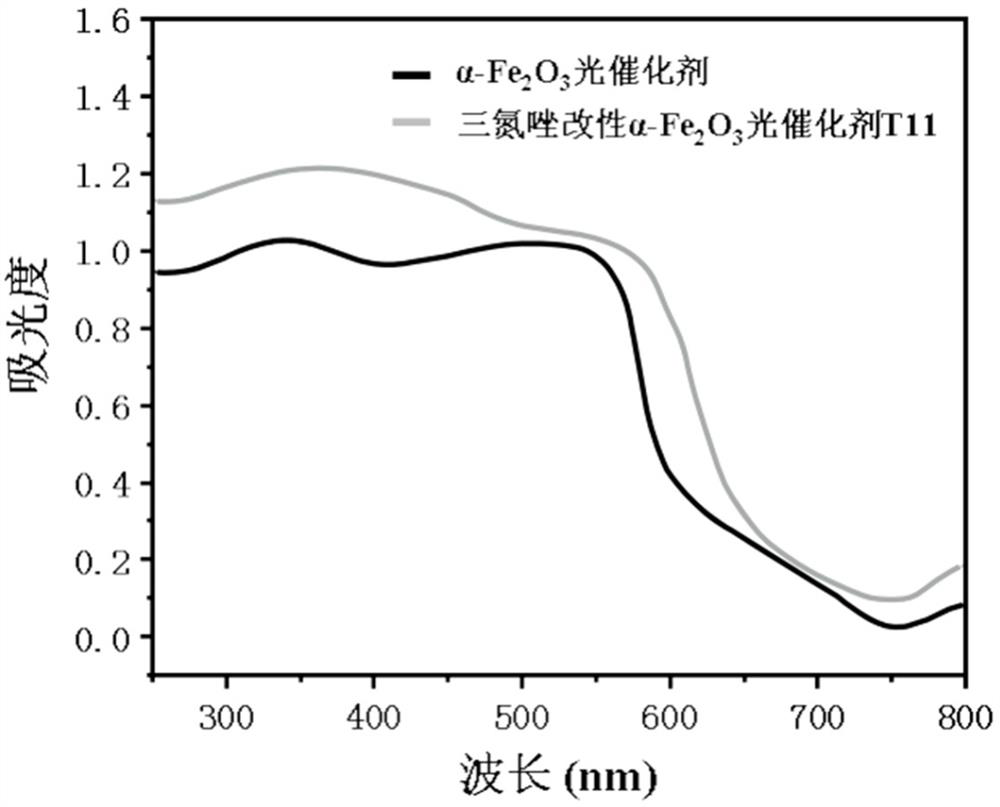

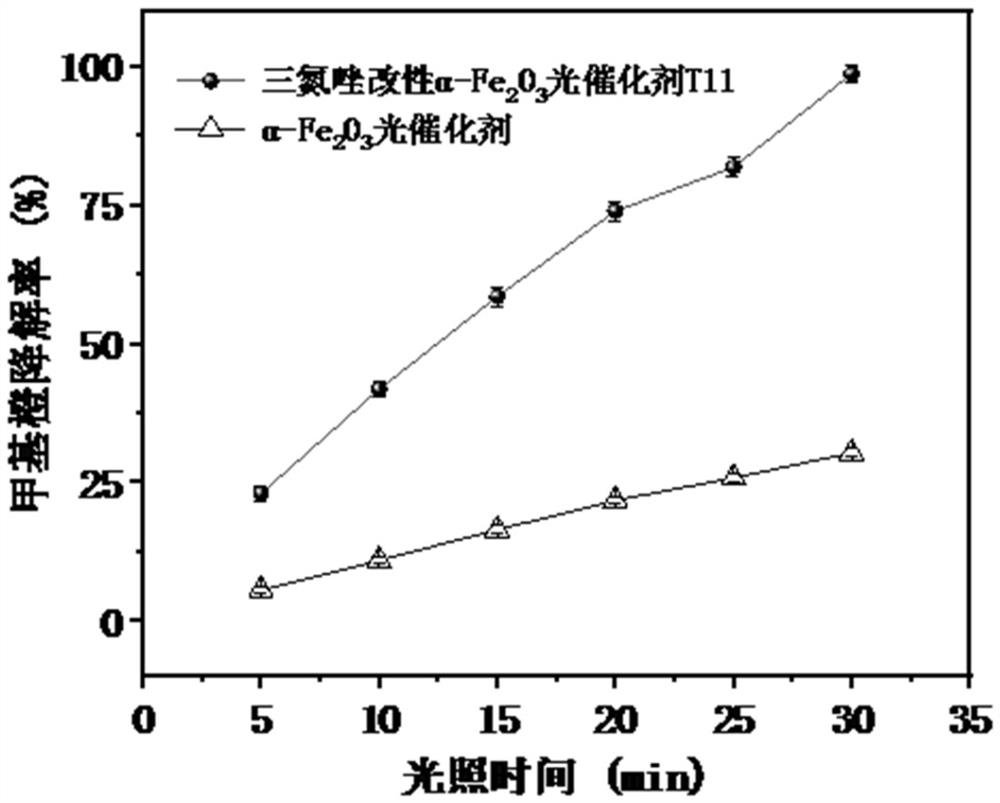

A technology of ferric oxide and photocatalyst, which is applied in the field of environmental treatment and can solve the problems of low utilization rate of ferric oxide photocatalyst and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

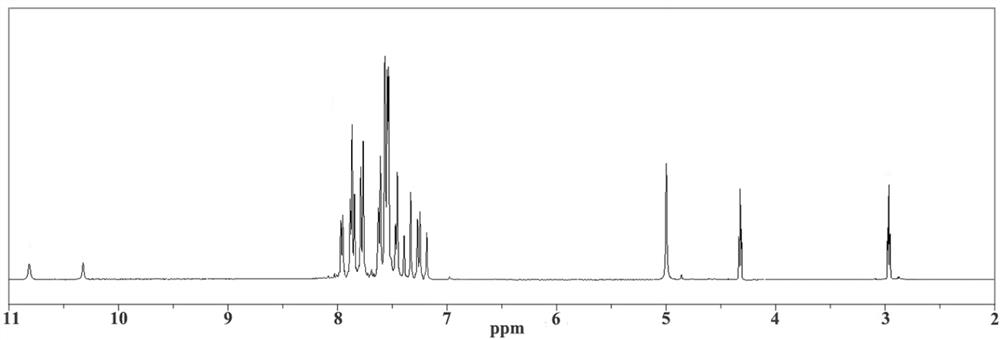

[0040] Preparation of modified triazole-modified ferric oxide photocatalyst T1:

[0041] (1) Add 7.41 g of 2,3-dihydrobenzofuran-5-carbaldehyde, 9.98 g of ethyl nitroacetate, 1.95 g of sodium azide, and 150 mL of DMSO into a round-bottomed flask in sequence, stir evenly, and add 0.67 g g Aluminum trichloride, water bath at 70 °C and stirring, TLC monitoring the reaction, after the reaction is complete, add 80 mL of deionized water and 3 drops of concentrated hydrochloric acid to inhibit AlCl 3 was hydrolyzed, extracted three times with 50 mL of ethyl acetate, and the organic layers were combined, washed with saturated sodium chloride, dried over anhydrous sodium sulfate, removed under reduced pressure for ethyl acetate, and purified by column drying to obtain solid A2.

[0042] (2) 10.74 g of A2 solid and 50 mL of acetonitrile were sequentially added to the three-necked flask and stirred, 5.80 g (0.042 mol) of potassium carbonate was added, and 5.72 g of bromoethane (R) was ...

Embodiment 2

[0052] Preparation of modified triazole-modified ferric oxide photocatalyst T2:

[0053] Substitute 1-chloroisobutane for bromoethane (R 1 X), synthesis of triazole compound C2 modified ferric oxide photocatalyst T2.

Embodiment 3

[0055] Preparation of modified triazole-modified ferric oxide photocatalyst T3:

[0056] Substitute 1-chloro-2-methylbutane for bromoethane (R 1 X), synthesis of triazole compound C3 modified ferric oxide photocatalyst T3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com