Ultra-dry carbon dioxide foam generating device for coiled tubing and application thereof

A foam generating device, carbon dioxide technology, applied in the directions of transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult foaming, difficult to obtain dense and uniform, fast defoaming, etc. The effect of plug flow, improving generation efficiency, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

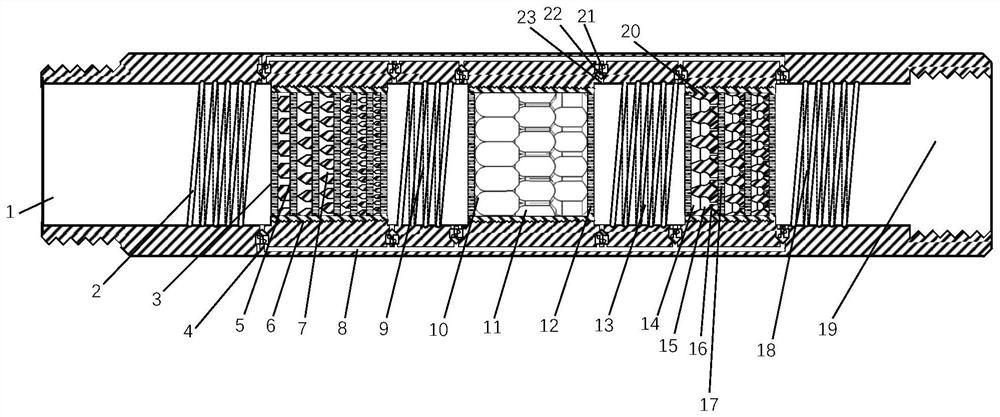

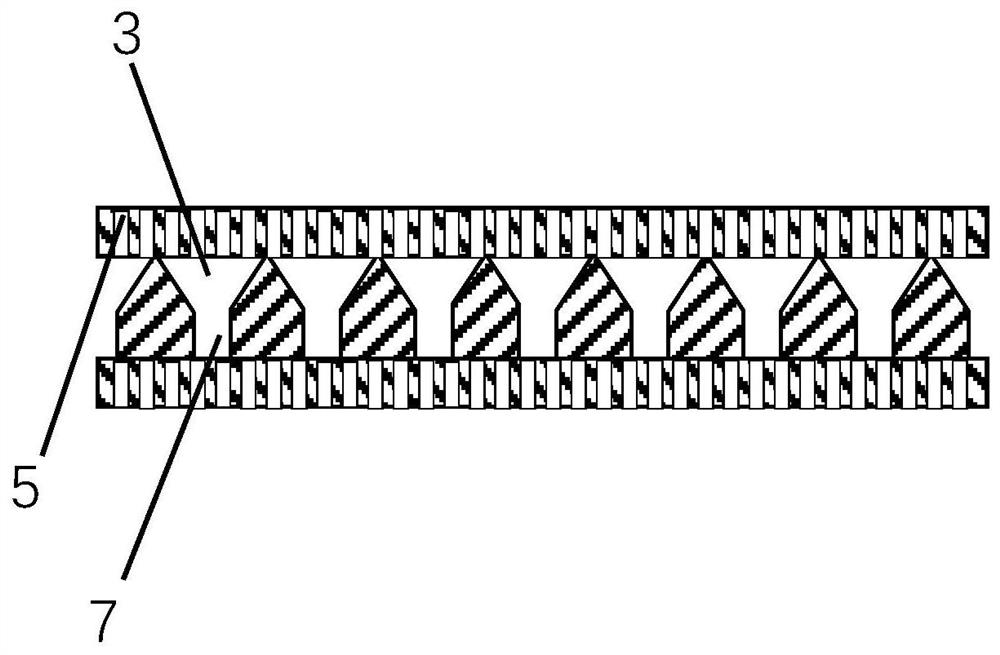

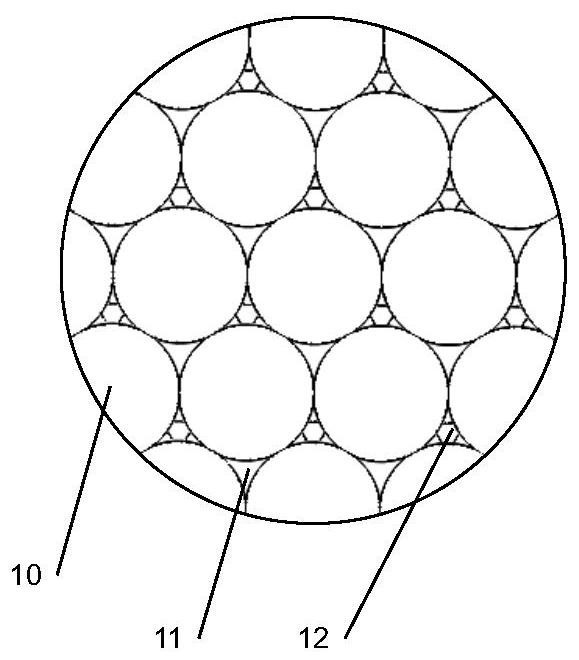

[0068] The ultra-dry carbon dioxide foam generating device for coiled tubing provided by the present invention has a schematic diagram of its overall structure as figure 1 As shown, it includes a water-locking module, a shearing vibration module and a water storage mixing module arranged in a steel pipe. In the steel pipe, a first-stage spiral diversion groove 2, Water-locking module, secondary spiral diversion tank 9 , shear vibration module, third-stage spiral diversion tank 13 , water storage mixing module 20 and fourth-stage spiral diversion tank 18 .

[0069] The injection port 1 of the ultra-dry carbon dioxide foam generating device for coiled tubing of the present invention is connected to the coiled tubing connector through external threads, and the coiled tubing connector is connected to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com