Sorting equipment for filtering small-size garlic

A small size, sorting technology, applied in the direction of filtration, solid separation, vegetable or fruit peeling, etc., can solve the problems of high work efficiency, increase the process, troublesome garlic processing, etc., to achieve high work efficiency and low utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

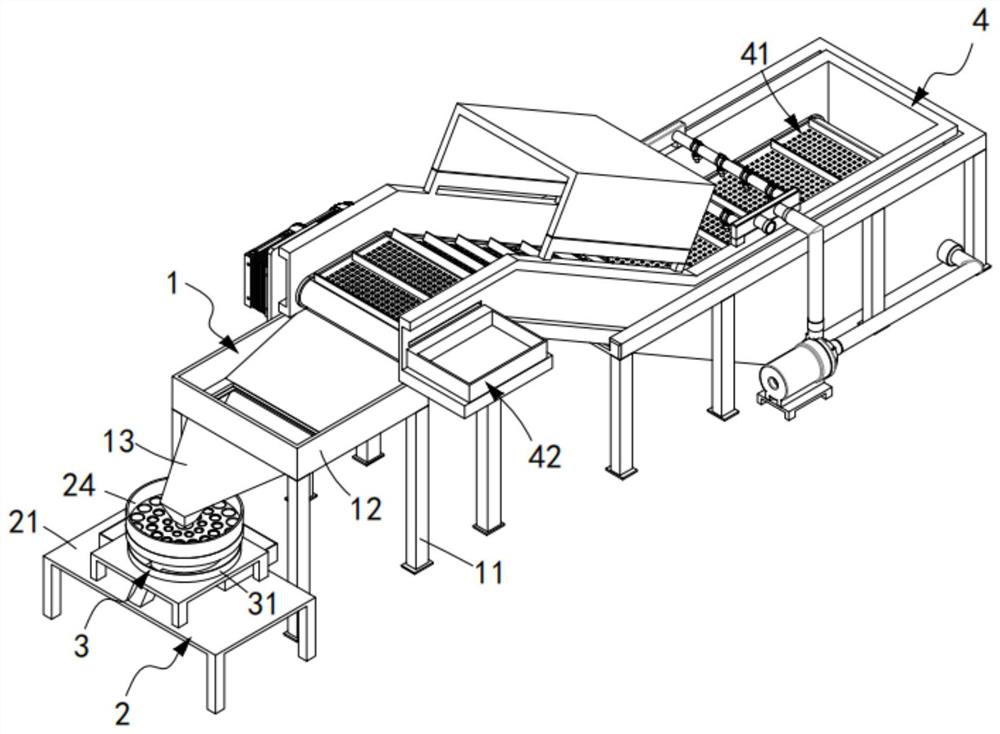

[0054] Such as Figure 1 to Figure 10 Shown, a sorting equipment for filtering small size garlic, comprising:

[0055] Feeding assembly 1, the feeding assembly 1 includes a feeding rack 11, a feeding box 12 placed on the feeding rack 11, and a feeding pipe 13 arranged at the bottom of the feeding box 12;

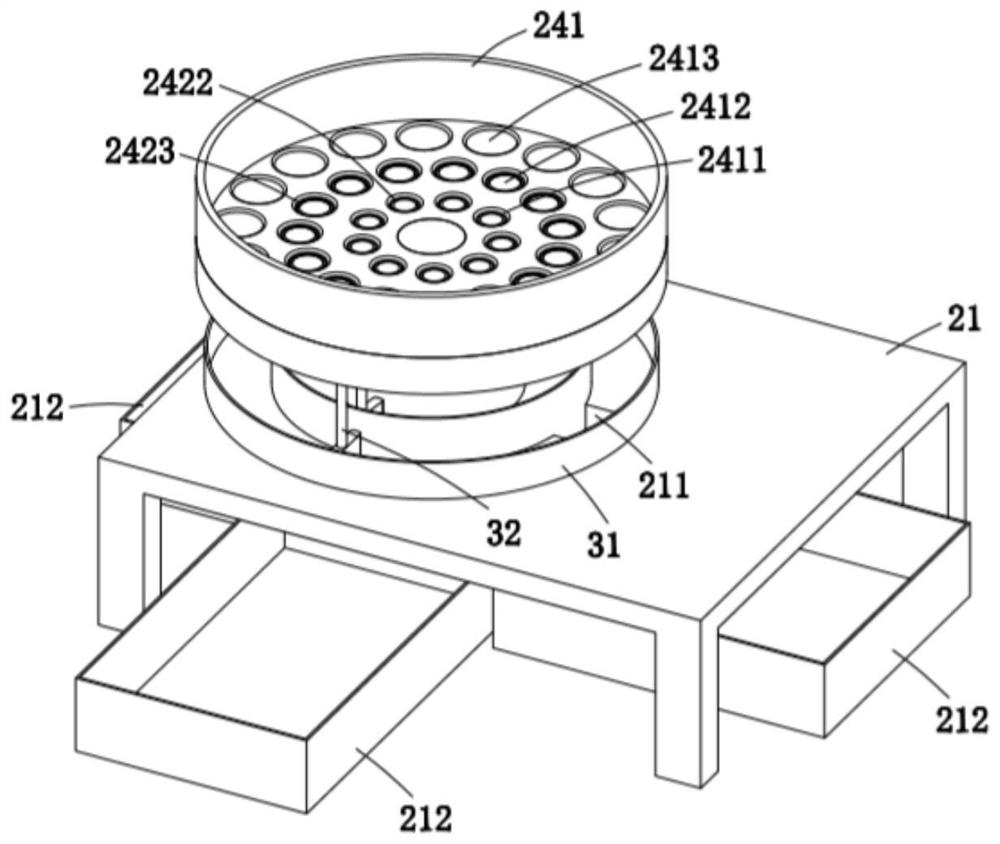

[0056] The sorting part 2, the sorting part 2 is arranged at one end of the feeding assembly 1 and is located below the feeding pipe 13, which includes a workbench 21 and a drive shaft 22 that is rotatably arranged on the workbench 21 , a drive motor 23 located at the bottom of the workbench 21 and disposed at one end of the drive shaft 22, a sorting assembly 24 disposed on the drive shaft 22;

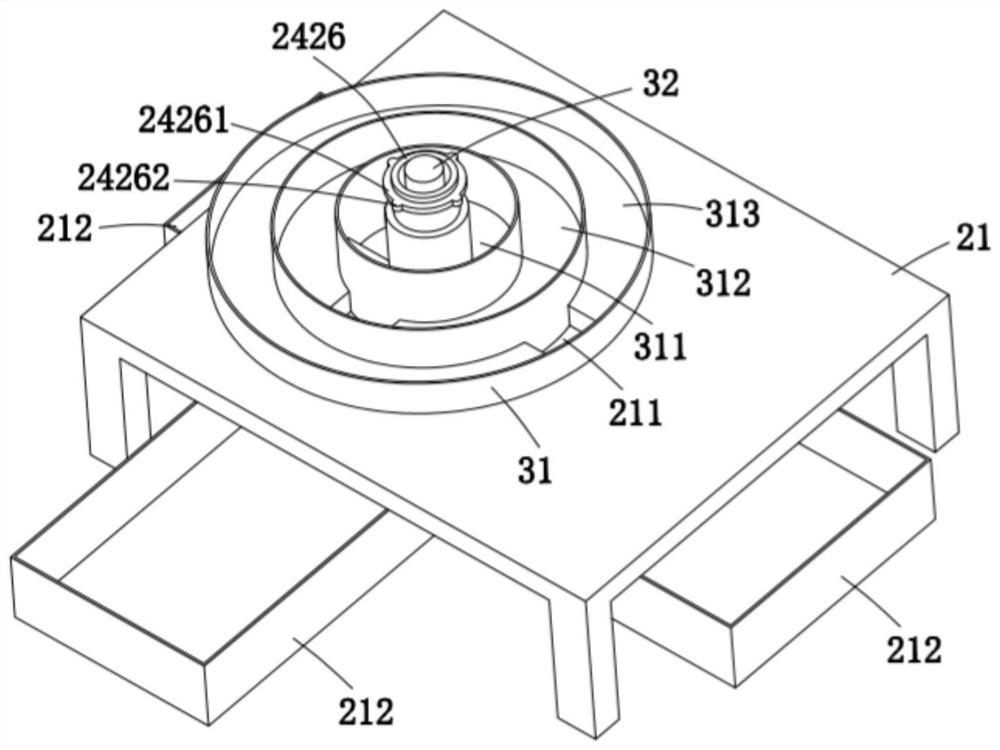

[0057] The blanking assembly 3, the blanking assembly 3 is located below the sorting assembly 24 and is arranged on the workbench 21, which includes the blanking assembly 3 including a blanking frame arranged on the workbench 21 31, and several pushing mechanisms 32, the blanking a...

Embodiment 2

[0077] Such as Figure 11 to Figure 15 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0078] further, such as image 3 As shown, the blanking area a311, the blanking area b312, and the blanking area c313 correspond to the sorting hole a2411, the sorting hole b2412, and the sorting hole c2413 respectively, and the workbench 21 is located on the lower The feeding area a311, the feeding area b312, and the feeding area c313 are also provided with a feeding port 211 respectively. The bottom of the feeding port 211 is provided with a corresponding receiving box 212. The feeding area a311, the feeding area b312 1. The shape of the feeding area c313 is in the shape of an annular groove, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com