Plastic plate deburring device for plastic product processing

A technology for plastic products and plastic plates, which is applied in manufacturing tools, metal processing equipment, grinding/polishing safety devices, etc., can solve problems such as hand stab wounds and poor collection effect of workers, and achieves increased applicability, good use effect, The effect of reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

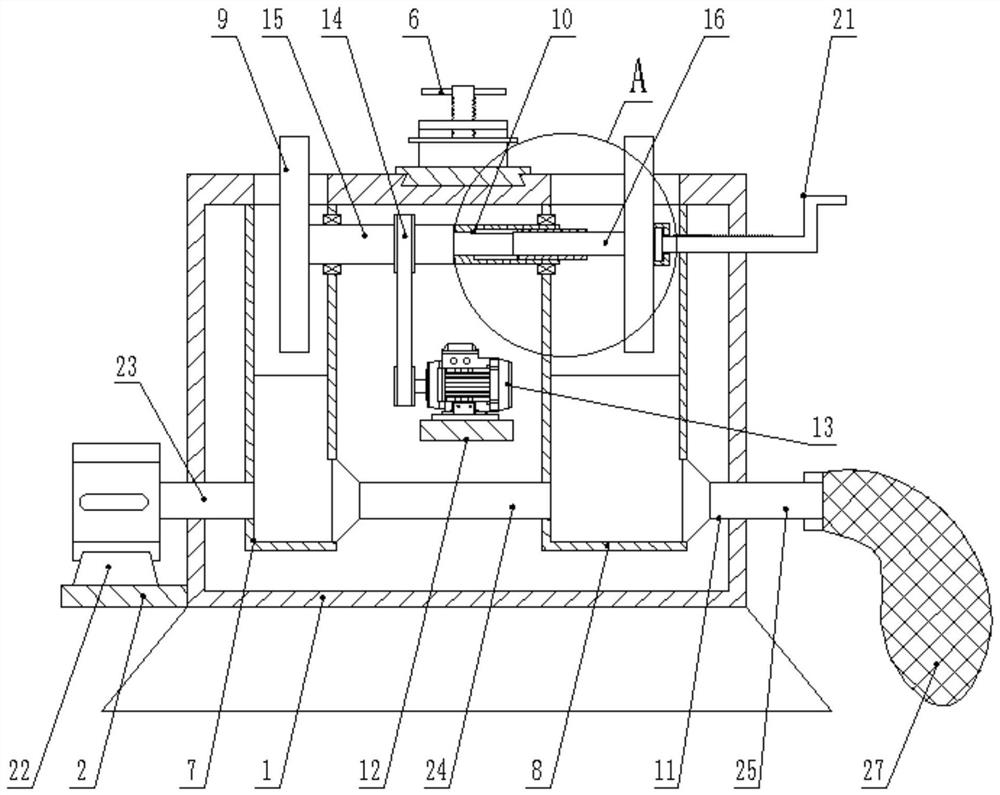

[0030] Example 1: Please refer to figure 1 , a plastic plate deburring device for processing plastic products, comprising a box body 1 and a mounting plate 2, the mounting plate 2 is fixedly welded on the left side of the box body 1;

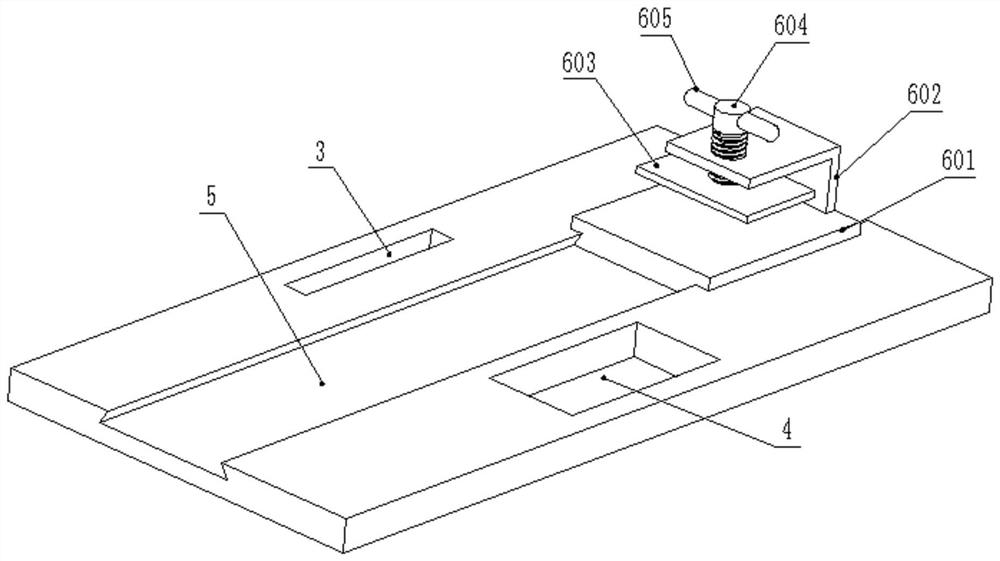

[0031] see figure 2 There is a first rectangular groove 3 on the left side of the upper surface of the box body 1, a second rectangular groove 4 is opened on the right side of the upper surface of the box body 1, and a wedge-shaped groove 5 is opened on the upper surface of the box body 1. Inside the wedge-shaped groove 5 The sliding connection has a clamping mechanism 6;

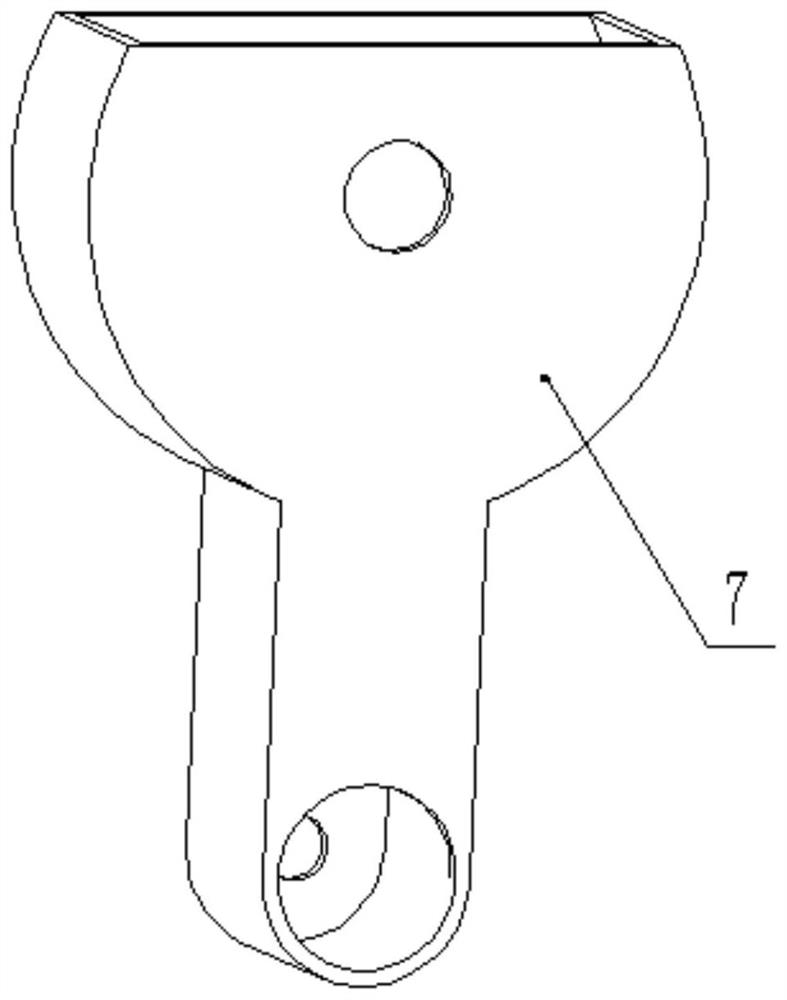

[0032] see figure 1 , the first rectangular slot 3 below the upper side wall of the box body 1 is fixedly connected with the left chip removal channel 7, and the second rectangular slot 4 under the upper side wall of the box body 1 is fixedly connected with the right chip removal channel 8, the left chip removal channel Both the channel 7 and the right chip removal channe...

Embodiment 2

[0045] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the hollow shaft 15 is rotationally connected to the left chip removal channel 7 and the right chip removal channel 8 through bearings.

[0046] The working principle of the present invention is as follows: through the labor-saving handle 605, the pressure bar 604 is rotated, the pressure plate 603 and the slide plate 601 are matched, the clamping mechanism 6 fixes the plastic plate, the motor 13 is started, and the belt transmission group 14 drives the hollow rotating shaft 15 to rotate, and the clamping mechanism 6 fixes the plastic plate. The mutual cooperation between the groove 17 and the limit bar 18 makes the grinding roller 9 on the right side keep rotating synchronously with the grinding roller 9 on the left side. Bar 19 simultaneously grinds and deburrs the left and right sides of the plastic plate; adjusts the lateral position of the right side grinding roller 9 in the right chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com