Synthesis method of nano KFI molecular sieve

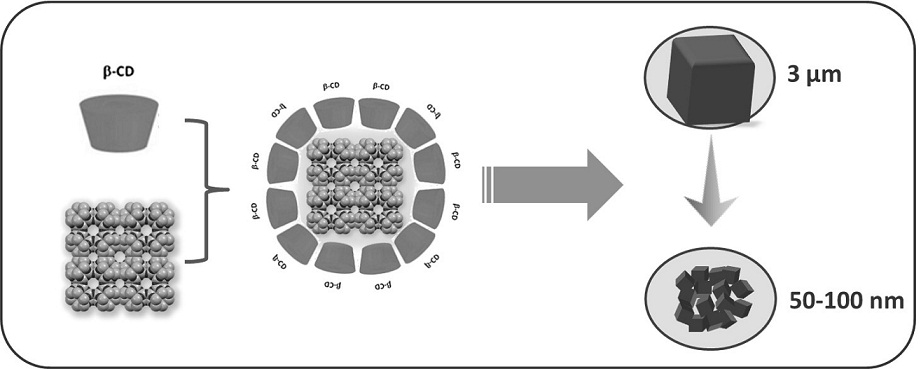

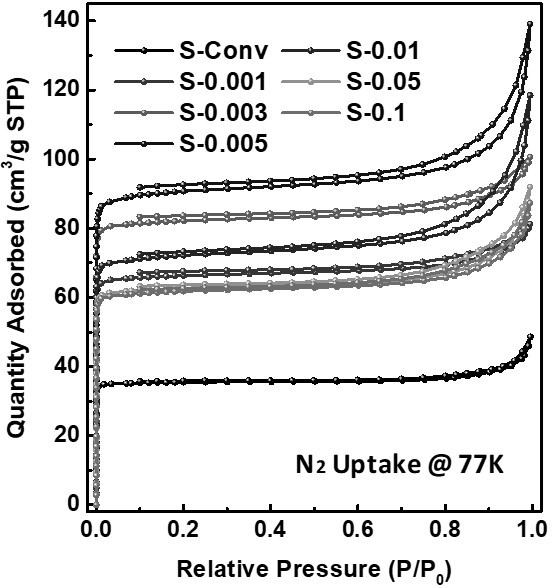

A molecular sieve and nanotechnology, applied in the synthesis field of nano KFI molecular sieve, can solve the problems of expensive template agent, difficult control of sub-nanometer size, large environmental pollution, etc., and achieve the effect of delaying crystal growth, low cost and strong catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

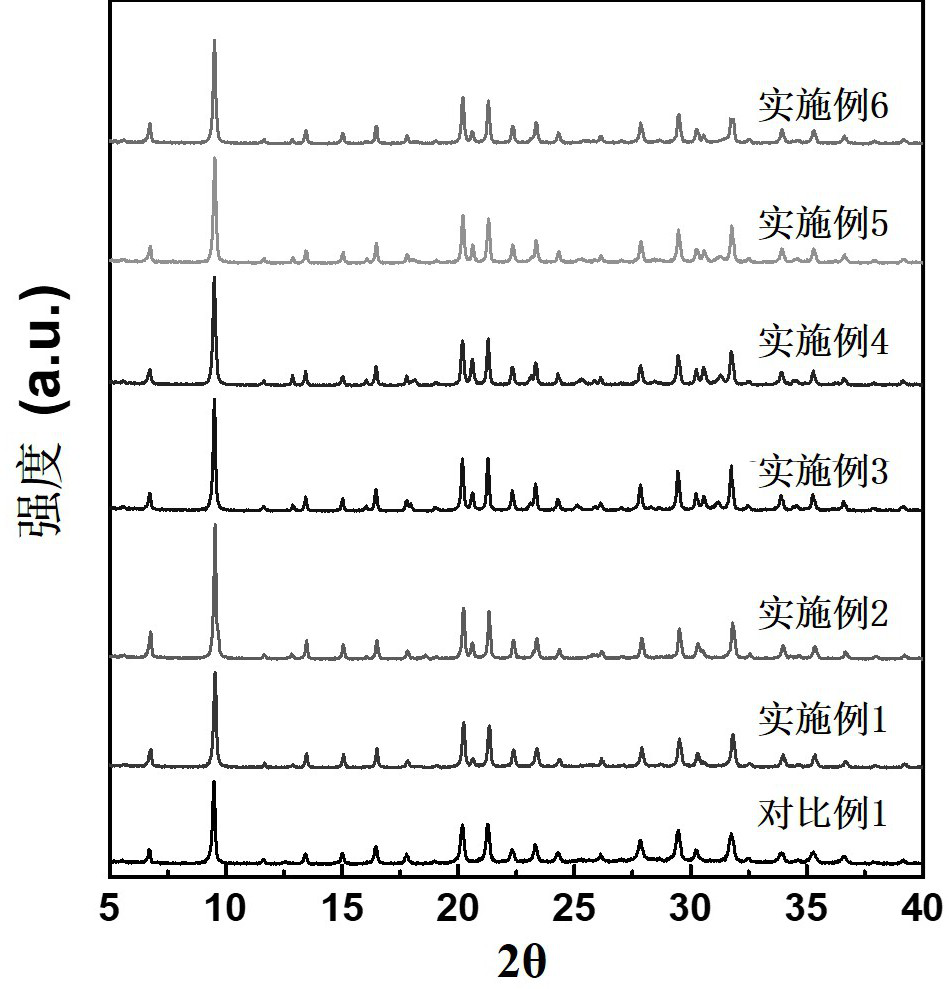

Examples

Embodiment 1

[0033] A method for synthesizing nano KFI molecular sieves, comprising the following steps:

[0034] 1) Preparation of A solution

[0035] Heat and stir the mixture of 0.28g of aluminum hydroxide, 0.36g of potassium hydroxide and 1.3mL of distilled water until clear and transparent, then cool at room temperature to obtain solution A, the heating temperature is 60°C, and the stirring rate is 300 rpm;

[0036]2) Preparation of B solution

[0037] At room temperature, dissolve 0.04g of solid strontium nitrate in 2.0mL of distilled water, then add 0.0002g of β-cyclodextrin and 1.7g of silica sol and stir evenly to obtain solution B;

[0038] 3) Precursor gel preparation

[0039] Take 2.0 mL of solution A and 2.4 mL of solution B and mix thoroughly, and stir to obtain the precursor gel;

[0040] 4) Molecular sieve synthesis

[0041] Transfer the precursor gel prepared in step (3) to a polytetrafluoroethylene-lined stainless steel autoclave, heat it statically in an oven at 150°...

Embodiment 2

[0043] A method for synthesizing nano KFI molecular sieves, comprising the following steps:

[0044] 1) Preparation of A solution

[0045] Heat and stir the mixture of 0.28g of aluminum hydroxide, 0.48g of potassium hydroxide and 2.6mL of distilled water until it becomes clear and transparent, then cool at room temperature to obtain solution A, the heating temperature is 50°C, and the stirring rate is 100 rpm;

[0046] 2) Preparation of B solution

[0047] At room temperature, dissolve 0.04 g of solid strontium nitrate in 3.4 mL of distilled water, then add 0.0006 g of β-cyclodextrin and continue stirring for 25 minutes, and 2.8 g of silica sol and continue stirring for 35 minutes to obtain solution B;

[0048] 3) Precursor gel preparation

[0049] Take 2 mL of solution A and solution B, mix thoroughly, and stir to obtain the precursor gel;

[0050] 4) Molecular sieve synthesis

[0051] The precursor gel prepared in step (3) was transferred to a polytetrafluoroethylene-lin...

Embodiment 3

[0053] A method for synthesizing nano KFI molecular sieves, comprising the following steps:

[0054] 1) Preparation of A solution

[0055] Heat and stir the mixture of 0.28g of aluminum hydroxide, 0.40g of potassium hydroxide and 2mL of distilled water until it becomes clear and transparent, then cool at room temperature to obtain solution A, the heating temperature is 90°C, and the stirring rate is 500 rpm;

[0056] 2) Preparation of B solution

[0057] At room temperature, dissolve 0.04 g of solid strontium nitrate in 3 mL of distilled water, then add 0.001 g of β-cyclodextrin and continue stirring for 30 minutes, then add 2.5 g of silica sol and continue stirring for 25 minutes to obtain solution B;

[0058] 3) Precursor gel preparation

[0059] Take 2 mL of solution A and solution B, mix thoroughly, and stir to obtain the precursor gel;

[0060] 4) Molecular sieve synthesis

[0061] Transfer the precursor gel prepared in step (3) to a polytetrafluoroethylene-lined stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com